This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3094389 Banjo Connector Screw, manufactured by Cummins, is a component used in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts designed to enhance the efficiency and reliability of truck systems. This Cummins part is integral to the fluid systems within these vehicles, ensuring the smooth operation of hydraulic and fuel systems.

Basic Concepts of Banjo Connector Screws

A Banjo Connector Screw is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with an integrated banjo fitting, which allows for the secure attachment of hoses. In the context of a truck’s hydraulic or fuel system, the Banjo Connector Screw facilitates the transfer of fluids under pressure, ensuring that the system operates efficiently and without leaks 1.

Purpose of the 3094389 Banjo Connector Screw

This part plays a specific role in the operation of a truck by connecting hoses or pipes to fittings within the hydraulic or fuel system. This connection is vital for maintaining the integrity of the system, as it ensures that fluids are transferred smoothly and without interruption. The screw’s design allows for a secure fit, which is crucial for preventing leaks and maintaining system pressure 2.

Key Features

The 3094389 Banjo Connector Screw is designed with several features that enhance its performance and durability. It is constructed from high-quality materials, typically steel or stainless steel, which provide resistance to corrosion and wear. The thread type is standardized to ensure compatibility with various fittings, and the design includes features that facilitate easy installation and removal. Additionally, the screw may have unique attributes such as a sealing washer integrated into the design to improve sealing capabilities 3.

Benefits

Using the 3094389 Banjo Connector Screw offers several advantages. Its design contributes to improved sealing capabilities, which helps prevent leaks in the system. The material composition provides resistance to corrosion, ensuring longevity even in harsh operating conditions. Furthermore, the screw is designed for ease of installation and removal, which simplifies maintenance procedures and reduces downtime for commercial trucks.

Installation Process

Proper installation of the 3094389 Banjo Connector Screw involves several steps to ensure a secure and leak-free connection. Begin by cleaning the fitting and the hose end to remove any debris or contaminants. Apply a compatible thread sealant to the threads of the screw to enhance the seal. Using the appropriate tools, screw the Banjo Connector into the fitting until it is hand-tight, then use a torque wrench to achieve the manufacturer’s specified torque setting. Finally, check for leaks by pressurizing the system and inspecting the connection.

Troubleshooting and Maintenance

Common issues with Banjo Connector Screws include leaks and connection failures. To diagnose these problems, inspect the connection for signs of wear, corrosion, or damage. Ensure that the screw is properly torqued and that the sealing washer is in good condition. Regular maintenance involves checking the connection for tightness and inspecting the screw and fittings for signs of wear. Replacing worn components promptly can help prolong the lifespan of the system.

Safety Considerations

When working with the 3094389 Banjo Connector Screw, it is important to observe several safety guidelines. Ensure that the system is depressurized before beginning any work to prevent injury from pressurized fluid. Use the correct tools and follow the manufacturer’s torque specifications to avoid over-tightening, which can damage the fitting or screw. Additionally, perform system pressure checks after installation to ensure that the connection is secure and leak-free.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance engine and power generation equipment. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial truck operations. Cummins’ reputation for excellence is built on its dedication to engineering excellence and customer satisfaction.

Cummins Engine Compatibility with Part 3094389

The Banjo Connector Screw, part number 3094389, manufactured by Cummins, is a critical component in the fuel and hydraulic systems of various Cummins engines. This part is designed to ensure a secure and leak-free connection between the banjo fitting and the fuel line or hydraulic hose.

ISX CM870 and QSB3.3 CM2250 EC

The ISX CM870 and QSB3.3 CM2250 EC engines both utilize the Banjo Connector Screw in their fuel systems. The ISX CM870, known for its robust performance in heavy-duty applications, and the QSB3.3 CM2250 EC, which is often found in agricultural and industrial machinery, both benefit from the reliability and precision of this component. The screw ensures that the connections remain tight and secure, preventing any potential leaks that could compromise engine performance.

QST30 CM2350 T101 and QST30 CM552

The QST30 CM2350 T101 and QST30 CM552 engines also incorporate the Banjo Connector Screw in their hydraulic systems. These engines, which are typically used in construction and mining equipment, rely on the integrity of hydraulic connections to maintain operational efficiency and safety. The screw’s design allows for easy installation and removal, facilitating maintenance and repairs.

Role of Part 3094389 Banjo Connector Screw in Engine Systems

The 3094389 Banjo Connector Screw is an essential component in various engine systems, facilitating the secure connection of fluid lines to critical engine components. Its role is significant in ensuring the efficient operation and reliability of these systems.

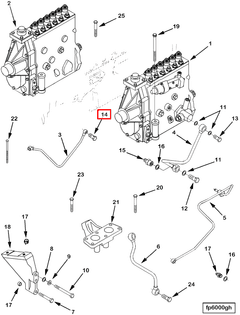

Fuel Injection Pump

In the fuel injection pump system, the 3094389 Banjo Connector Screw is used to connect the high-pressure fuel lines to the injectors. This connection ensures that fuel is delivered under precise pressure to the combustion chambers, enhancing fuel efficiency and engine performance. The secure fitting provided by the banjo connector screw prevents leaks, which is vital for maintaining the integrity of the fuel delivery system.

Fuel Pump

Within the fuel pump system, the 3094389 Banjo Connector Screw plays a role in connecting the fuel lines to the pump. This ensures a consistent flow of fuel from the tank to the engine. The reliable connection is essential for maintaining the pump’s efficiency and preventing fuel starvation, which could lead to engine misfires or stalling.

General Pump Systems

In broader pump systems, including those used for lubrication or cooling, the 3094389 Banjo Connector Screw is employed to connect fluid lines to the pump inlets and outlets. This ensures that the pump can effectively circulate fluids throughout the engine, maintaining optimal operating temperatures and reducing wear on moving parts.

Fuel Recirculation

For fuel recirculation systems, the 3094389 Banjo Connector Screw is used to connect the recirculation lines back to the fuel tank or to the intake side of the fuel pump. This helps in managing fuel pressure and temperature, ensuring that excess fuel is properly returned to the system without causing leaks or pressure drops.

Exhaust System

In some exhaust systems, particularly those involving emissions control components like Exhaust Gas Recirculation (EGR) valves, the 3094389 Banjo Connector Screw is used to connect the gas lines. This ensures that exhaust gases are accurately metered and recirculated back into the intake system, helping to reduce nitrogen oxides (NOx) emissions and comply with environmental regulations.

Conclusion

The 3094389 Banjo Connector Screw, through its applications in these various engine systems, plays a significant role in maintaining the efficiency, reliability, and performance of the engine. Its design and features contribute to secure and leak-free connections, which are essential for the optimal operation of hydraulic and fuel systems in commercial trucks.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367317.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.