3094183

Hexagon Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, part number 3094183, manufactured by Cummins, is a critical component in the maintenance and operation of commercial trucks. Cummins, a renowned name in the commercial truck industry, produces a variety of parts aimed at enhancing the reliability and efficiency of truck operations. This part, the 3094183 Hexagon Head Cap Screw, is essential for securing various components within truck systems.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a fastener distinguished by its hexagonal head, facilitating efficient tightening and loosening with a wrench or socket. These screws are extensively used in mechanical assemblies to secure components. Their design ensures a robust grip and resistance to loosening, making them ideal for applications requiring durability and reliability 1.

Purpose of the 3094183 Hexagon Head Cap Screw in Truck Operation

The 3094183 Hexagon Head Cap Screw is employed in the operation and maintenance of commercial trucks to secure components across various truck systems. Its applications include fastening engine parts and securing chassis components, ensuring that critical elements remain firmly in place under operational stress. This screw is vital for maintaining the stability and functionality of the truck, contributing to the integrity of the mechanical assemblies it is part of.

Key Features of the 3094183 Hexagon Head Cap Screw

This Cummins part is designed with specific features that enhance its functionality and durability. It is made from high-quality materials, ensuring resistance to wear and corrosion. The screw features a precise thread type that provides a strong grip, while its head design allows for easy installation and removal using standard tools. These characteristics contribute to the screw’s reliability in demanding truck environments 2.

Benefits of Using the 3094183 Hexagon Head Cap Screw

Utilizing this part offers several advantages. It provides enhanced security for fastened components, reducing the risk of loosening over time. The screw’s design facilitates ease of installation and removal, allowing for efficient maintenance procedures. Additionally, its resistance to loosening ensures that components remain securely fastened, contributing to the safe and reliable operation of the truck.

Installation and Usage Guidelines

Proper installation of the 3094183 Hexagon Head Cap Screw involves several steps to ensure it functions correctly. Begin by selecting the appropriate size and type of screw for the application. Use a torque wrench to tighten the screw to the manufacturer’s specified torque, ensuring it is secure without over-tightening, which could damage the screw or the component it is fastening. Recommended tools for installation include a socket wrench compatible with the screw’s head size.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws, such as stripping or corrosion, can affect their performance. To address stripping, ensure the correct torque is applied during installation to avoid over-tightening. For corrosion, regular inspection and cleaning of the screw and its surroundings can prevent buildup that leads to corrosion. In cases where a screw is damaged, replacement with a new screw of the same specifications is recommended.

Maintenance Tips

Regular maintenance of the 3094183 Hexagon Head Cap Screw is vital for ensuring its longevity and reliable performance. Inspect the screw periodically for signs of wear, corrosion, or loosening. Cleaning the screw and its surrounding area can prevent debris buildup that may lead to corrosion. Following these maintenance practices helps maintain the screw’s integrity and the overall performance of the truck.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance parts, Cummins has established a reputation for excellence. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the efficiency and reliability of commercial trucks. Cummins’ dedication to quality is evident in its parts, including the 3094183 Hexagon Head Cap Screw, which embodies the company’s standards for durability and performance.

Cummins Engine Compatibility with Hexagon Head Cap Screw 3094183

The Cummins Hexagon Head Cap Screw part number 3094183 is a versatile component designed to fit a variety of Cummins engines. This screw is integral in securing various parts within the engine assembly, ensuring stability and reliability. Below is a detailed look at the engines that are compatible with this specific part.

ISB and QSB Series

- ISB CM850

- QSB5.9 CM850

These engines, part of the ISB and QSB series, utilize the 3094183 screw in several critical applications. The screw’s robust design ensures it can withstand the high stresses and vibrations inherent in these engine models.

ISM Series

- ISM CM570/870

- ISM CM876

The ISM series engines benefit from the 3094183 screw in various mounting and fastening applications. Its precision engineering makes it an ideal choice for maintaining the integrity of engine components in these models.

ISX Series

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

The ISX series engines, known for their power and efficiency, incorporate the 3094183 screw in several key areas. This screw’s high strength and durability are essential for the demanding conditions these engines operate under.

ISZ Series

- ISZ13 CM2150 Z105

The ISZ series engine also relies on the 3094183 screw for various fastening needs. Its design ensures that the engine’s components remain securely in place, contributing to the overall performance and longevity of the engine.

QSM and QST Series

- QSM11 CM876

- QST30 CM552

- QSX11.9 CM2250 ECF

These engines, part of the QSM and QST series, use the 3094183 screw in multiple applications. The screw’s precision and strength are crucial for maintaining the structural integrity of these engines.

C GAS PLUS CM556

The C GAS PLUS CM556 engine also incorporates the 3094183 screw in its assembly. This screw’s compatibility with this specific engine model ensures that all components are securely fastened, contributing to the engine’s overall reliability and performance.

By integrating the 3094183 Hexagon Head Cap Screw into these Cummins engines, the manufacturer ensures that each model benefits from a reliable and durable fastening solution. This screw’s compatibility across various engine series highlights its versatility and importance in maintaining engine integrity.

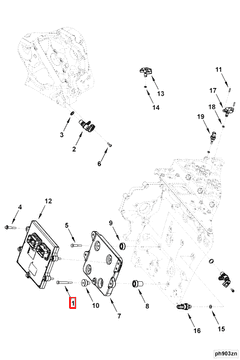

Role of Part 3094183 Hexagon Head Cap Screw in Engine Systems

The part 3094183 Hexagon Head Cap Screw is instrumental in securing various components within engine systems, ensuring their stability and proper function.

In the air cleaner mounting, this screw plays a key role in attaching the air cleaner assembly to the engine, maintaining a secure fit that is essential for efficient air filtration.

For the brake system, it is used in securing brake components, contributing to the overall safety and reliability of the braking mechanism.

Within the engine, the screw is utilized to fasten various engine components, ensuring they remain in place under the high stresses and vibrations typical of engine operation.

In the drive system, it secures components such as drive shafts and couplings, which are vital for transmitting power from the engine to the wheels.

For the fan, the screw is employed to attach the fan to its housing or the engine, ensuring it operates efficiently to cool the engine.

In harness and electronic control module wiring, it secures wiring harnesses and modules, protecting the electrical connections and ensuring reliable operation of the engine’s electronic systems.

Within the housing of various engine components, such as the thermostat housing, the screw ensures a tight seal, preventing leaks and maintaining the integrity of the system.

For the thermostat, it is used to secure the thermostat in place, ensuring it can accurately regulate engine temperature.

In terms of location, the screw is often used to secure sensors and other components in their designated positions within the engine bay.

For the air intake connection, it ensures a secure connection between the air intake system and the engine, which is vital for optimal engine performance.

In the module and engine control, the screw is used to fasten control modules and sensors, ensuring they are correctly positioned and functioning as intended.

Within plumbing systems, such as the engine oil primer and fuel lines, the screw secures fittings and connections, ensuring there are no leaks and the systems operate efficiently.

For the fuel filter, it is used to attach the filter to the fuel line, ensuring it remains in place and functions correctly to clean the fuel before it reaches the engine.

In the primer system, the screw secures components that are essential for priming the engine with oil before start-up, ensuring the engine is properly lubricated.

Within engine lubricating systems, it is used to secure oil passages and fittings, ensuring the lubrication system operates effectively.

Finally, in the water tube bracket, the screw ensures the bracket is securely attached, maintaining the structural integrity of the cooling system.

Conclusion

The 3094183 Hexagon Head Cap Screw by Cummins is a vital component in the maintenance and operation of commercial trucks. Its design and features ensure durability, reliability, and ease of use, making it an essential part for securing various components within truck systems. Proper installation, maintenance, and understanding of its role in engine systems contribute to the overall efficiency and safety of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.