This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Head Cap Screw, part number 3093904, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces a range of components that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part plays a significant role in securing various parts within the truck’s structure.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the cap screw includes a threaded shaft that engages with the internal threads of a nut or a tapped hole, providing a secure connection. Cap screws are commonly used in various industries for their strength and reliability in fastening applications 1.

Purpose and Role in Truck Operation

This part serves a specific purpose in the context of commercial trucks. It is utilized to secure critical components, ensuring they remain firmly in place under the demanding conditions of heavy-duty operations. This screw contributes to the overall operation and maintenance of truck components by providing a robust fastening solution that can withstand significant stress and vibration 2.

Key Features

The 3093904 Hexagon Head Cap Screw boasts several key features that enhance its performance in heavy-duty applications. It is composed of high-strength materials, typically alloy steel, which provides durability and resistance to wear. The screw features a coarse thread type, which allows for quick and secure fastening. Its hexagonal head design ensures easy installation and removal using standard tools. Additionally, the screw may include unique attributes such as a corrosion-resistant coating to enhance its performance in various environments 3.

Benefits

Using the 3093904 Hexagon Head Cap Screw offers several benefits. Its high-strength material composition ensures durability, making it suitable for heavy-duty applications. The screw’s design resists loosening, which is crucial in environments where vibrations are common. Furthermore, the hexagonal head allows for ease of installation and removal, reducing downtime during maintenance procedures 4.

Installation and Usage Guidelines

Proper installation of the 3093904 Hexagon Head Cap Screw is vital to ensure its effectiveness. It is recommended to use a torque wrench to achieve the specified torque settings, which can be found in the manufacturer’s guidelines. The use of the correct tools, such as a socket wrench, ensures that the screw is tightened to the appropriate level without over-tightening, which could lead to damage.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening due to vibration and corrosion. To troubleshoot these issues, regular inspections should be conducted to ensure the screws remain tight and free from corrosion. Maintenance tips include applying a thread locker to prevent loosening and using a corrosion-resistant lubricant to protect the screw from environmental factors.

Compatibility and Applications

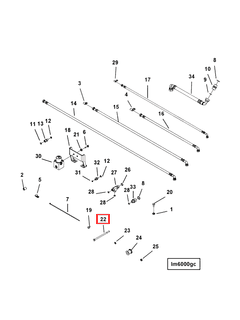

The 3093904 Hexagon Head Cap Screw is typically used in various applications within commercial trucks, securing components such as engine mounts, chassis parts, and other critical assemblies. Its design and material make it suitable for a range of fastening needs within the truck industry.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a range of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality, reliable components for the commercial truck industry. The company’s product range includes engines, filtration systems, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications.

Cummins Engine Part 3093904: Hexagon Head Cap Screw

The Cummins part number 3093904, a Hexagon Head Cap Screw, is a critical component in the assembly and maintenance of several Cummins engines. This part is designed to provide secure fastening in various applications within the engine systems.

QST30 CM2350 T101 and QST30 CM552

The Hexagon Head Cap Screw (3093904) is integral to the QST30 CM2350 T101 and QST30 CM552 engines. These engines, while differing in specific configurations and applications, share common design elements that necessitate the use of this particular screw.

In the QST30 CM2350 T101 engine, the 3093904 screw is often used in the assembly of engine blocks, cylinder heads, and other critical components. Its robust design ensures that these parts remain securely fastened under the high stress and varying temperatures typical of engine operation.

Similarly, in the QST30 CM552 engine, the Hexagon Head Cap Screw plays a vital role in maintaining the integrity of the engine’s structure. This screw is typically employed in areas where precise alignment and secure fastening are paramount, such as in the mounting of engine accessories and the fastening of various engine covers and panels.

The use of the 3093904 screw in both engines underscores its importance in ensuring the reliability and performance of Cummins engines. Its design and material properties make it suitable for the demanding conditions encountered in engine environments, providing a dependable solution for securing engine components.

Role of Part 3093904 Hexagon Head Cap Screw in Engine Systems

The part 3093904 Hexagon Head Cap Screw is integral to the assembly and functionality of various engine components. Its robust design ensures secure fastening, which is essential for maintaining the integrity and performance of the engine system.

Aftercooler

In the aftercooler system, the 3093904 screw is used to fasten components that facilitate the cooling of compressed air. This ensures that the air temperature is optimal before it enters the engine, enhancing efficiency and performance.

Connection

For engine connections, the 3093904 screw plays a key role in securing hoses, pipes, and other conduits. This is vital for maintaining a sealed and efficient flow of fluids and gases throughout the engine system.

Air Crossover

In the air crossover system, the screw is employed to fasten components that direct airflow between different parts of the engine. This ensures uniform air distribution, which is essential for balanced combustion and engine performance.

Filter

Within the filter assembly, the 3093904 screw is used to secure filter housings and elements. This maintains the structural integrity of the filter, ensuring it effectively captures contaminants and protects the engine from damage.

Oil Bypass

In the oil bypass system, the screw is crucial for fastening components that regulate oil flow. This ensures that the engine receives a consistent supply of lubricant, which is essential for reducing friction and wear on moving parts.

Manifold

The manifold system utilizes the 3093904 screw to secure intake and exhaust manifolds. This is important for maintaining the structural integrity of the manifold, ensuring efficient air and exhaust flow.

Lubricating Oil Access

Finally, in the lubricating oil access system, the screw is used to fasten components that provide access to the engine’s lubrication system. This ensures that the engine can be properly maintained and lubricated, which is essential for its longevity and performance.

Conclusion

The 3093904 Hexagon Head Cap Screw is a vital component in the assembly and maintenance of Cummins engines and commercial trucks. Its robust design, high-strength material, and resistance to loosening make it an ideal choice for securing critical components in heavy-duty applications. Proper installation and maintenance of this part are essential to ensure the reliability and performance of the engine system.

-

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding (Cengage Learning, 2019).

↩ -

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines (The MIT Press, 2010).

↩ -

A. J. Wharton, Diesel Engines (Butterworth-Heinemann Ltd, 1991).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.