This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Hexagon Head Cap Screw, part number 3093765, is a vital component in the realm of heavy-duty trucks. Cummins, a renowned manufacturer in the automotive industry, produces this screw, which is integral to the fastening systems used in trucks. This part ensures secure and reliable connections, contributing to the overall performance and durability of heavy-duty vehicles.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using standard tools such as wrenches or sockets. The design of the screw includes a threaded shaft that engages with internal threads in the material being fastened, providing a strong and stable connection. These screws are commonly used in various applications where a high degree of security and resistance to loosening is required 1.

Purpose of the Cummins Hexagon Head Cap Screw in Trucks

The Cummins Hexagon Head Cap Screw plays a significant role in the operation and maintenance of heavy-duty trucks. It is utilized in critical applications where secure fastening is necessary to ensure the integrity and safety of the vehicle. This screw is often found in engine components, chassis assemblies, and other structural parts where vibrations and dynamic loads are present. Its purpose is to provide a reliable connection that can withstand the rigors of heavy-duty use 2.

Key Features

The Cummins Hexagon Head Cap Screw boasts several specific features that enhance its performance and reliability. Its hexagonal head design allows for easy engagement with standard tools, facilitating quick and efficient installation and removal. The screw is composed of high-quality materials, typically alloy steel, which offers excellent strength and durability. Additionally, the threading on the screw is precision-machined to ensure a secure and tight fit, reducing the risk of loosening over time 3.

Benefits

Using the Cummins Hexagon Head Cap Screw offers several advantages. Its durable material composition ensures long-lasting performance even under demanding conditions. The screw’s resistance to loosening is enhanced by its precise threading and the secure engagement provided by the hexagonal head. Furthermore, the ease of use with standard tools makes it a convenient choice for both installation and maintenance tasks.

Installation Guidelines

Proper installation of the Cummins Hexagon Head Cap Screw is crucial for ensuring optimal performance and longevity. To install the screw, first, ensure that the mating threads are clean and free of debris. Use a wrench or socket to begin threading the screw into the designated hole. Apply steady, even pressure to avoid cross-threading. Once the screw is engaged, continue tightening until the desired torque specification is achieved, using a torque wrench for accuracy. Finally, double-check the connection to ensure it is secure and properly seated.

Troubleshooting Common Issues

Common issues with Hexagon Head Cap Screws can include loosening, corrosion, or damage to the head. If a screw becomes loose, it should be re-tightened to the specified torque. In cases of corrosion, the affected area should be cleaned, and an appropriate anti-corrosion treatment applied. If the head of the screw is damaged, it may be necessary to replace the screw to ensure a secure connection.

Maintenance Tips

Regular maintenance of the Cummins Hexagon Head Cap Screw can help prevent issues and extend its service life. Periodically check the tightness of the screw and re-torque as necessary. Inspect the screw for signs of corrosion or damage, and apply protective coatings if needed. Keeping the screw and surrounding area clean will also contribute to its longevity and performance.

Cummins: A Brief Overview

Cummins is a well-established manufacturer with a rich history in the automotive industry. The company is known for its commitment to quality and innovation, offering a wide range of products designed to meet the demands of heavy-duty applications. Cummins’ dedication to excellence is evident in their comprehensive product range, which includes engines, powertrains, and various components like the Cummins Hexagon Head Cap Screw. Their focus on reliability and performance makes them a trusted name in the industry.

Cummins Hexagon Head Cap Screw 3093765 in Engine Applications

The Cummins Hexagon Head Cap Screw, part number 3093765, is a critical component in various engine assemblies. This part is engineered to provide robust fastening solutions, ensuring the integrity and stability of engine components. Below are the engines where this screw is utilized, grouped by their respective engine families.

Cummins QST30 CM552 Engines

In the Cummins QST30 CM552 engines, the Cummins Hexagon Head Cap Screw is employed in several key areas. Its primary function is to secure various engine parts, ensuring they remain tightly fastened under operational stresses. This screw is particularly vital in maintaining the alignment and stability of components such as engine mounts, brackets, and covers. The precision and strength of the screw contribute to the overall reliability and performance of the engine.

Cummins QST30 CM552 Group

The Cummins QST30 CM552 engines are part of a broader group of engines that share similar design principles and components. The Cummins Hexagon Head Cap Screw is a common element across this group, facilitating the assembly and maintenance of these engines. Its use in this group underscores the importance of standardized components in ensuring consistency and ease of repair across different engine models.

Application Considerations

When installing the Cummins Hexagon Head Cap Screw in Cummins engines, it is crucial to follow proper torque specifications and use the correct thread lubricants. This ensures that the screw achieves the necessary clamping force without risking damage to the threads or the fastened components. Proper installation is key to maintaining the structural integrity of the engine and preventing potential failures.

Maintenance and Replacement

Regular inspection of the Cummins Hexagon Head Cap Screw is recommended during routine maintenance checks. Ensuring that the screw remains tight and free from corrosion or damage is essential for the longevity and performance of the engine. If any signs of wear or damage are detected, the screw should be replaced promptly to avoid compromising the engine’s structural integrity.

Role of Part 3093765 in Engine Systems

The Cummins Hexagon Head Cap Screw is instrumental in securing various components within engine systems, ensuring stability and performance. Its applications span across multiple critical assemblies, contributing to the overall integrity and functionality of the engine.

Thermostat Housing Assembly

In the thermostat housing assembly, the Cummins Hexagon Head Cap Screw plays a significant role in fastening the housing to the engine block. This secure attachment is essential for maintaining the seal around the thermostat, which regulates coolant flow and ensures the engine operates within optimal temperature ranges. The screw’s hexagonal head allows for efficient tightening and loosening, facilitating easy maintenance and replacement of the thermostat if necessary.

Engine Control Module Mounting

The Cummins Hexagon Head Cap Screw is also utilized in the mounting of the Engine Control Module (ECM). Proper securing of the ECM is vital for its accurate functioning, as it controls various engine parameters and communicates with other vehicle systems. The screw ensures that the ECM remains firmly in place, unaffected by vibrations or movements that could otherwise disrupt its operation.

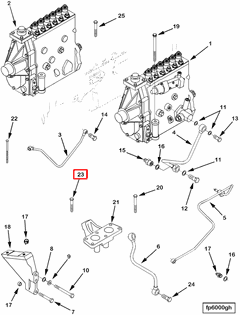

Fuel Injection Pump

In the fuel injection pump system, the Cummins Hexagon Head Cap Screw is employed to fasten components that are subject to high pressure and stress. Its robust design ensures that parts remain securely attached, preventing leaks and maintaining the precision required for fuel delivery. This contributes to the engine’s efficiency and performance, as well as ensuring reliable fuel injection under varying operating conditions.

Auxiliary Cooling System

Within the auxiliary cooling system, the Cummins Hexagon Head Cap Screw is used to secure additional cooling components, such as radiators or intercoolers. These systems are essential for dissipating heat from the engine and other high-temperature areas. The screw’s reliable fastening capability ensures that these components remain in place and function correctly, contributing to the engine’s overall cooling efficiency.

Top-Level Assembly Housing

In top-level assembly housings, such as those for the thermostat, the Cummins Hexagon Head Cap Screw provides the necessary strength to hold together complex assemblies. This is particularly important in environments where components are exposed to significant thermal expansion and contraction. The screw’s design ensures that these housings remain intact, protecting sensitive internal parts and maintaining the structural integrity of the assembly.

General Application in Engine Systems

Across various engine systems, the Cummins Hexagon Head Cap Screw is a versatile fastener that ensures components are securely attached. Whether it’s mounting sensors, securing brackets, or fastening covers, this screw plays a fundamental role in maintaining the structural and functional integrity of the engine. Its widespread use underscores its importance in ensuring that engine systems operate smoothly and reliably.

Conclusion

The Cummins Hexagon Head Cap Screw, part number 3093765, is a critical component in the fastening systems of heavy-duty trucks and engines. Its robust design, precise threading, and ease of use with standard tools make it an essential part for ensuring the reliability and performance of heavy-duty vehicles. Proper installation, regular maintenance, and timely replacement are key to maximizing the longevity and effectiveness of this part in various engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.