The 3093760 Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-respected name in the industry, produces this screw to meet the demanding requirements of heavy-duty truck operations. This screw is integral to ensuring the secure assembly of various components within commercial trucks, contributing to both the functionality and safety of the vehicle.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. These screws are commonly used in mechanical assemblies to secure components together. They function by converting rotational force into axial force, which clamps the components securely in place. The hexagonal shape of the head provides a firm grip, reducing the risk of slippage during installation or removal 1.

Purpose and Role in Truck Operation

The 3093760 Hexagon Head Cap Screw plays a specific role in the operation of commercial trucks. It is designed to secure critical components within the truck’s engine and chassis. By providing a reliable fastening solution, this screw helps maintain the structural integrity of the truck, ensuring that parts remain securely in place under various operating conditions. This contributes to the overall functionality and safety of the vehicle, as loose components can lead to mechanical failures or accidents 2.

Key Features

The 3093760 Hexagon Head Cap Screw boasts several key features that enhance its performance in heavy-duty applications. Its design includes a hexagonal head for easy installation and removal, and it is made from high-quality materials to ensure durability and resistance to wear. The screw’s thread pitch and length are optimized for the specific applications it is intended for, providing a secure and lasting connection. Additionally, the screw may feature coatings or treatments to improve corrosion resistance, further enhancing its reliability in demanding environments.

Benefits

Using the 3093760 Hexagon Head Cap Screw offers several benefits. Its durable construction ensures long-lasting performance, even under the strenuous conditions typical of commercial truck operations. The screw’s design resists loosening, which is crucial for maintaining secure fastenings over time. Additionally, the hexagonal head allows for easy installation and removal, saving time and effort during maintenance procedures.

Installation Guidelines

Proper installation of the 3093760 Hexagon Head Cap Screw is vital to ensure secure fastening. Begin by cleaning the mating surfaces to remove any debris or contaminants. Use a wrench or socket that fits the hexagonal head to tighten the screw to the specified torque. It is important to follow the torque specifications provided by Cummins to avoid over-tightening, which can damage the screw or the components being fastened, or under-tightening, which can lead to insecure connections. Always use the correct tools and follow best practices to ensure a secure and reliable installation.

Troubleshooting and Maintenance

Common issues with Hexagon Head Cap Screws include loosening over time and corrosion. To troubleshoot these issues, regularly inspect the screws for signs of wear or damage. If a screw appears loose, tighten it to the specified torque. If corrosion is present, consider replacing the screw to prevent further degradation. Maintenance tips include keeping the screws and surrounding areas clean and dry, and applying a corrosion-resistant coating if necessary to prolong the lifespan of the screw and ensure continued reliable performance.

Cummins: Manufacturer Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has built a reputation for producing high-quality, reliable components for the commercial truck industry. Their extensive product range includes engines, filtration systems, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to innovation, quality, and customer satisfaction makes them a trusted source for truck components, including the 3093760 Hexagon Head Cap Screw.

Hexagon Head Cap Screw 3093760 in Cummins Engines

The Cummins Hexagon Head Cap Screw part number 3093760 is a critical component in several Cummins engine models. This part is integral to the assembly and maintenance of the QSK60 CM500 and QSK60 CM850 MCRS engines.

In the QSK60 CM500 engine, the 3093760 screw is utilized in various applications where secure fastening is essential. Its design ensures that it can withstand the operational stresses and environmental conditions within the engine compartment.

Similarly, in the QSK60 CM850 MCRS engine, the 3093760 screw plays a pivotal role in maintaining the structural integrity of the engine. Given the robust nature of the MCRS variant, this screw is subjected to higher loads and stresses, making its reliability and durability crucial.

Both engines benefit from the precision engineering of the 3093760 screw, ensuring that it fits seamlessly into the engine’s design. This screw is a testament to Cummins’ commitment to quality and performance, providing a reliable fastening solution across different engine configurations.

Role of Part 3093760 Hexagon Head Cap Screw in Engine Systems

The part 3093760 Hexagon Head Cap Screw is integral to the assembly and securement of various engine components, ensuring stability and proper function throughout the engine’s operation.

Base Rail

In the assembly of the base rail, the 3093760 screw is used to fasten the rail to the engine block or frame. This securement is essential for maintaining the structural integrity of the base rail, which supports other engine components and contributes to the overall stability of the engine.

Engine Mounting Plate

The engine mounting plate is another area where the 3093760 screw plays a significant role. It is employed to attach the mounting plate to the engine block, ensuring a firm and vibration-resistant connection. This is vital for the engine’s secure placement within the vehicle’s chassis and for absorbing the dynamic forces generated during operation.

Flexplate

When it comes to the flexplate, the 3093760 screw is utilized to secure the flexplate to the crankshaft. This connection is fundamental for transmitting torque from the engine to the transmission, facilitating the transfer of power to the vehicle’s wheels.

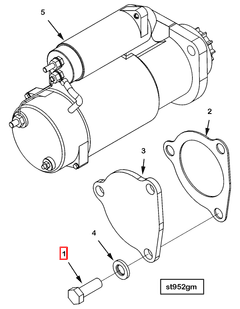

Starting Motor

In the starting motor assembly, the 3093760 screw is instrumental in attaching the motor to its mounting bracket. This ensures that the starting motor is held in place securely, allowing it to engage with the flexplate effectively and start the engine without any misalignment or undue stress on the components.

Starting Motor Mounting

Lastly, for the starting motor mounting, the 3093760 screw is used to fasten the mounting bracket to the engine block or transmission housing. This secure attachment is necessary for the starting motor to function correctly, providing the necessary force to turn the engine over during startup while withstanding the mechanical stresses involved.

Conclusion

The 3093760 Hexagon Head Cap Screw is a critical component in the assembly and maintenance of Cummins engines, particularly the QSK60 CM500 and QSK60 CM850 MCRS models. Its robust design and reliable performance ensure the secure fastening of various engine components, contributing to the overall stability and functionality of the engine. Proper installation and maintenance of this screw are essential to ensure the longevity and reliability of the engine systems in which it is used.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.