3093752

Hexagon Head Cap Screw

Cummins®

AVAILABLE

10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Part #3093752 Hexagon Head Cap Screw is a specialized fastener designed for use in commercial trucks. Its purpose is to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of the vehicle. This screw is commonly applied in engine components, chassis assembly, and other areas where strong and durable fastening is required.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The design of the screw includes external threading that engages with internal threads in the material being fastened, creating a strong and secure connection. In fastening applications, these screws are valued for their ease of use, strength, and resistance to loosening 1.

Role of the 3093752 Hexagon Head Cap Screw in Truck Operation

The 3093752 Hexagon Head Cap Screw plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various critical areas, including engine components where it helps secure parts that are subject to high stress and vibration. In chassis assembly, this screw ensures that structural components remain firmly attached, contributing to the overall stability and safety of the truck. Additionally, it is used in other areas where durable and reliable fastening is necessary to maintain the vehicle’s performance and longevity 2.

Key Features

The 3093752 Hexagon Head Cap Screw boasts several key features that enhance its performance and durability. Its hexagonal head design allows for easy and efficient tightening and loosening, reducing the risk of damage to the screw or surrounding components. The material composition of the screw is selected for its strength and resistance to corrosion, ensuring longevity in harsh operating conditions. The threading of the screw is designed to provide a strong and secure connection, while any unique attributes further contribute to its reliability and performance.

Benefits

Using the 3093752 Hexagon Head Cap Screw offers several benefits. It provides improved fastening strength, ensuring that components remain securely attached even under high stress and vibration. The screw’s design resists loosening, maintaining a tight and reliable connection over time. It is also easy to install and remove, saving time and effort during maintenance procedures. Additionally, its durability in harsh operating conditions contributes to the longevity of the fastener and the components it secures.

Installation and Usage Guidelines

Proper installation and usage of the 3093752 Hexagon Head Cap Screw are vital to ensure a secure and reliable fastening. Follow these step-by-step instructions:

- Select the appropriate wrench or socket that fits the hexagonal head of the screw.

- Align the screw with the designated threading in the material being fastened.

- Begin tightening the screw by hand to ensure proper engagement of the threads.

- Use the wrench or socket to continue tightening the screw until the desired torque is achieved. Refer to the manufacturer’s torque specifications for the correct value.

- Ensure that the screw is fully seated and that the connection is secure.

- Periodically check the tightness of the screw during maintenance procedures to ensure it remains secure.

Troubleshooting and Maintenance

Common issues that may arise with Hexagon Head Cap Screws include loosening, corrosion, or damage. To address these issues and prolong the lifespan of the fastener, follow these troubleshooting and maintenance procedures:

- Regularly inspect the screw for signs of loosening, corrosion, or damage.

- If loosening is detected, re-tighten the screw to the manufacturer’s torque specifications.

- To prevent corrosion, apply a corrosion-resistant coating or lubricant to the screw and surrounding areas.

- If the screw is damaged, replace it with a new one to maintain the integrity of the fastening.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products and services designed to meet the diverse needs of its customers, ensuring reliable and efficient performance in various applications.

Cummins Engine Compatibility with Part 3093752

The Cummins part 3093752, a Hexagon Head Cap Screw, is designed to fit seamlessly within a variety of Cummins engines. This part is integral to the assembly and maintenance of these engines, ensuring secure fastening and reliable operation.

Engines Compatible with Part 3093752

- 4B3.9

- 6B5.9

- B4.5

- QSB3.9 30 CM550

- QSB4.5 CM850 (CM2850)

- QSB5.9 30 CM550

- QST30 CM2350 T101

- QST30 CM552

The Hexagon Head Cap Screw is a critical component in these engines, providing the necessary strength and durability for various applications. Its design ensures a tight and secure fit, which is essential for maintaining the integrity of engine components and ensuring optimal performance.

Grouping of Compatible Engines

-

QSB Series:

- QSB3.9 30 CM550

- QSB4.5 CM850 (CM2850)

- QSB5.9 30 CM550

-

QST Series:

- QST30 CM2350 T101

- QST30 CM552

-

Other Models:

- 4B3.9

- 6B5.9

- B4.5

The Hexagon Head Cap Screw is engineered to meet the specific requirements of each engine model, ensuring compatibility and performance across the board.

Role of Part 3093752 Hexagon Head Cap Screw in Engine Systems

The part 3093752 Hexagon Head Cap Screw is instrumental in securing and maintaining the integrity of various engine components. Its application spans across multiple systems, ensuring that each part functions as intended under operational conditions.

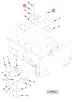

Air Compressor Upfit Kit

In the air compressor upfit kit, the Hexagon Head Cap Screw is used to fasten the compressor to the engine block. This secure attachment is vital for the efficient operation of the compressor, which relies on stable mounting to deliver consistent air pressure.

Camshaft and Gear

For the camshaft and gear assembly, the screw ensures that the camshaft is properly aligned and secured within the engine. This alignment is essential for the precise timing of valve operations, directly influencing engine performance and efficiency.

Connecting Rod and Piston

Within the connecting rod and piston system, the Hexagon Head Cap Screw plays a role in securing the connecting rod to the crankshaft. This connection is fundamental for transmitting the force from the piston to the crankshaft, thereby converting linear motion into rotational motion.

Cylinder Head and Cylinder Head Lifting Fixture

When lifting the cylinder head, the screw is employed in the cylinder head lifting fixture to provide a secure grip. This ensures that the cylinder head can be safely and effectively removed or installed without risk of damage.

Drive Systems

In both the auxiliary pump drive and the front gear train accessory drive, the screw is utilized to fasten components securely. This is important for the reliable transfer of power and the smooth operation of auxiliary systems.

Guard and Support Systems

The front engine guard and support systems utilize the Hexagon Head Cap Screw to attach guards and supports to the engine frame. This not only protects internal components but also provides structural integrity to the engine assembly.

Sensor and Electronic Systems

For the engine speed sensor and the electronic control module wiring harness, the screw ensures that sensors and wiring are firmly attached. This is crucial for accurate data collection and the reliable operation of electronic control systems.

Plumbing and Fluid Systems

In plumbing systems such as the cylinder block, fuel filter, and oil cooler water, the screw is used to secure fittings and connections. This ensures that fluid systems remain leak-free and operate under the correct pressure.

Accessory Drives and Pulleys

The accessory drive pulley system relies on the Hexagon Head Cap Screw to attach pulleys and drives to the engine. This secure attachment is necessary for the efficient operation of accessories like the alternator and air conditioning compressor.

Performance and Package Systems

In performance parts and package systems, the screw is used to secure high-performance components, ensuring they withstand the increased stress and demands of enhanced engine operations.

Vent Tube and Auxiliary Cooling System

Finally, in the vent tube and auxiliary cooling system, the screw is employed to secure components that manage engine ventilation and cooling. This is essential for maintaining optimal engine temperature and preventing overheating.

The Hexagon Head Cap Screw, part 3093752, thus plays a multifaceted role in ensuring the secure and efficient operation of various engine systems. Its application across different components underscores its importance in maintaining engine integrity and performance 3.

Conclusion

The Cummins Part #3093752 Hexagon Head Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure fastening, durability, and resistance to loosening, contributing to the overall performance and longevity of the vehicle. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Rolf Isermann. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5579481.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.