This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3093733 Hexagon Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. This part plays a role in securing various components within the truck’s mechanical assemblies. Cummins, a well-regarded manufacturer in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications.

Basic Concepts of Hexagon Head Cap Screws

A Hexagon Head Cap Screw is a type of fastener characterized by its hexagonal head, which allows for efficient tightening and loosening using a wrench or socket. The structure of these screws typically includes a threaded shaft and a head designed to distribute clamping force evenly. In mechanical assemblies, cap screws serve to join components securely, ensuring structural integrity and proper function 1.

Purpose and Role in Truck Operation

The 3093733 is specifically designed for use in commercial trucks, where it plays a role in securing critical components. This screw contributes to the overall operation and maintenance of truck components by providing a reliable fastening solution that can withstand the rigors of heavy-duty use. Its application ensures that parts remain securely attached, which is vital for the safe and efficient operation of the vehicle.

Key Features

The 3093733 features a hexagonal head design, which facilitates easy installation and removal using standard tools. It is composed of high-quality materials that offer durability and resistance to corrosion. The threading specifications of this screw are tailored to provide a strong grip and secure fastening. These features enhance its functionality and reliability in demanding applications.

Benefits

Using the 3093733 offers several benefits, including enhanced durability, resistance to loosening, and ease of installation and removal. Compared to other types of fasteners, this screw provides a more secure and lasting solution for heavy-duty applications. Its design and material composition contribute to its superior performance in commercial truck environments.

Installation and Usage

Proper installation of the 3093733 involves adhering to torque specifications to ensure a secure fastening solution. Recommended tools for installation include wrenches or sockets that fit the hexagonal head. Best practices for installation include cleaning the fastening area, using the correct torque settings, and periodically checking the screw to ensure it remains secure.

Troubleshooting and Maintenance

Common issues associated with Hexagon Head Cap Screws include loosening over time and corrosion. Troubleshooting these issues involves checking for proper torque, ensuring the screw is made of corrosion-resistant material, and reapplying torque if necessary. Maintenance tips to prolong the life of the screw include regular inspection for signs of wear or corrosion and retightening as needed to maintain a secure fastening solution.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer with a strong reputation for producing high-quality automotive components. The company has a history of innovation and commitment to customer satisfaction, which is reflected in their product line, including the 3093733. Cummins’ expertise in manufacturing ensures that their components meet the high standards required for commercial truck applications 2.

Integration of Hexagon Head Cap Screw Part 3093733 in Cummins Engines

The Cummins-manufactured 3093733 is a critical component in various Cummins engine models, including the ISBE CM800. This screw is integral to the assembly and maintenance of these engines, ensuring structural integrity and operational efficiency.

Application in ISBE CM800 Engines

In the ISBE CM800 engines, the 3093733 is utilized in several key areas. Its primary function is to secure various engine components, ensuring that they remain tightly fastened and properly aligned. This is crucial for maintaining the engine’s performance and longevity. The screw’s design, featuring a hexagonal head, allows for efficient torque application using standard tools, facilitating ease of installation and removal during maintenance procedures.

Versatility Across Cummins Engine Models

The versatility of the 3093733 extends beyond the ISBE CM800. Cummins employs this part in a range of their engine models, leveraging its robust design and reliable performance. The screw’s application in these engines underscores its importance in the overall assembly and maintenance process, contributing to the engines’ operational efficiency and durability.

Importance in Engine Assembly

The use of the 3093733 in Cummins engines highlights its critical role in engine assembly. By providing a secure fastening solution, this screw helps to maintain the structural integrity of the engine, ensuring that all components are properly aligned and secured. This is essential for the engine’s performance and longevity, as any misalignment or looseness can lead to operational issues and potential failures.

Maintenance and Reliability

During maintenance procedures, the 3093733 proves to be a reliable component. Its design allows for easy installation and removal, facilitating efficient maintenance and repair processes. This reliability is crucial for ensuring that the engine can be serviced quickly and effectively, minimizing downtime and maintaining operational efficiency.

Role of Part 3093733 Hexagon Head Cap Screw in Engine Systems

The 3093733 is integral to the assembly and securement of various components within engine systems. Its robust design ensures reliable fastening, which is essential for the proper functioning and safety of the engine.

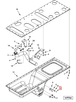

Fuel System Integration

In the fuel system, the 3093733 is used to attach the fuel plumbing bracket. This bracket supports the fuel supply tube, ensuring it remains in the correct position and alignment. The secure fastening provided by the screw is vital for maintaining the integrity of the fuel delivery system, preventing leaks and ensuring consistent fuel flow to the engine.

Injector Plumbing Assembly

The screw also plays a significant role in the injector plumbing assembly. It is employed to fasten components that connect the fuel injectors to the fuel rail. This secure connection is necessary to maintain the precise fuel injection timing and pressure, which are critical for engine performance and efficiency.

Oil Pan and Plumbing Connections

In the oil system, the 3093733 is utilized to attach the oil pan to the engine block. This connection is essential for maintaining the structural integrity of the oil pan and ensuring it remains securely in place. Additionally, the screw is used in the oil pan plumbing to fasten tubes and fittings, ensuring there are no leaks in the oil circulation system. This is important for maintaining proper lubrication of engine components, which is essential for reducing wear and tear.

General Plumbing Applications

Beyond specific components, the 3093733 is widely used throughout various plumbing applications within the engine. It secures hoses, tubes, and fittings, ensuring that all fluid systems—whether for fuel, oil, or coolant—remain intact and function as intended. This widespread use underscores the screw’s versatility and importance in maintaining the overall reliability of the engine system.

Conclusion

The 3093733 Hexagon Head Cap Screw is a vital component in the assembly and maintenance of commercial truck engines, particularly those manufactured by Cummins. Its robust design, ease of installation, and reliable performance make it an essential part for ensuring the structural integrity and operational efficiency of engine systems. Proper installation, maintenance, and periodic checks are crucial for maximizing the screw’s effectiveness and longevity in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.