3092409

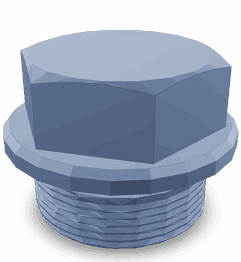

Hexagon Flange Head Cap Screw

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3092409 Hexagon Flange Head Cap Screw is a significant component in heavy-duty truck applications. Designed for commercial trucks, this screw is essential in the assembly and maintenance of various truck components. Cummins, a prominent figure in the automotive industry, ensures this part meets the stringent demands of heavy-duty applications.

Basic Concepts and Functionality

Hexagon Flange Head Cap Screws are based on fundamental mechanical principles. These screws are used for fastening and securing components in truck mechanics. The hexagonal flange head design allows for efficient torque application, ensuring a secure fit. In truck mechanics, these screws are vital in holding together critical components, contributing to the vehicle’s structural integrity and functionality 1.

Purpose and Role in Truck Operation

The 3092409 Hexagon Flange Head Cap Screw serves a specific purpose in truck operation. It secures various components, ensuring they remain firmly in place under dynamic truck operation conditions. This screw’s role is crucial in maintaining the truck’s integrity and performance, as it helps withstand the stresses and vibrations encountered during operation 2.

Key Features

The 3092409 Hexagon Flange Head Cap Screw has several key features that enhance its performance in heavy-duty applications. Its hexagonal flange head design allows for easy and efficient tightening and loosening. The screw’s material composition is tailored to withstand the harsh conditions of truck operation, offering durability and resistance to wear and tear. Additionally, unique attributes such as corrosion resistance or specific thread design further contribute to its effectiveness in commercial truck applications 3.

Benefits

The 3092409 Hexagon Flange Head Cap Screw offers several benefits that contribute to the efficiency and safety of truck operations. These include improved fastening strength, ensuring components remain securely in place, and resistance to vibration, crucial in the dynamic environment of a truck. The ease of installation and removal of this screw also enhances maintenance efficiency, allowing for quick and straightforward component replacements or adjustments.

Installation and Usage Guidelines

Correct installation and usage of the 3092409 Hexagon Flange Head Cap Screw are vital for its optimal performance and longevity. Guidelines recommend specific torque settings to ensure the screw is tightened to the appropriate level without over-tightening, which could lead to damage. Proper alignment during installation is also crucial, as is the use of correct tools and techniques to avoid damaging the screw or the components it secures.

Troubleshooting and Maintenance

Common issues with the 3092409 Hexagon Flange Head Cap Screw, such as loosening or corrosion, can be addressed through regular maintenance. This includes periodic inspections to check for signs of wear or damage, cleaning to remove any debris or corrosive substances, and adhering to replacement schedules to ensure the screw continues to perform effectively. These maintenance practices help prolong the screw’s life and ensure the continued reliability of the truck.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its expertise in diesel engine manufacturing. The company has a history of innovation and commitment to quality, providing reliable components for heavy-duty trucks. Cummins’ role in the industry is marked by its dedication to producing parts that meet the demanding requirements of commercial vehicle applications, ensuring safety, efficiency, and durability in truck operations.

Hexagon Flange Head Cap Screw 3092409 in Cummins Engines

The Cummins part number 3092409, a Hexagon Flange Head Cap Screw, is a critical component in several Cummins engine models. This part is designed to secure various engine components, ensuring structural integrity and operational efficiency. Here’s how it fits into specific Cummins engines:

4B3.9 and 6B5.9 Engines

In the 4B3.9 and 6B5.9 engines, the 3092409 screw is used to fasten components that require a strong and reliable connection. These engines are known for their robust performance, and the screw’s design ensures that critical parts remain securely in place under high stress and varying operational conditions.

B3.3, QSB3.3 CM2150, and QSK19 CM2350 K114 Engines

For the B3.3, QSB3.3 CM2150, and QSK19 CM2350 K114 engines, the 3092409 screw plays a vital role in maintaining the alignment and stability of engine components. These engines are designed for both durability and efficiency, and the screw’s precision engineering is essential for their reliable performance.

QST30 CM552 Engine

In the QST30 CM552 engine, the 3092409 screw is used to secure components that are subject to significant mechanical forces. This engine is engineered for high-performance applications, and the screw’s ability to withstand stress and provide a tight, secure fit is crucial for its operation.

Each of these engines benefits from the use of the 3092409 Hexagon Flange Head Cap Screw, which ensures that all fastened components remain securely in place, contributing to the overall reliability and performance of the engine.

Role of Part 3092409 Hexagon Flange Head Cap Screw in Engine Systems

The part 3092409 Hexagon Flange Head Cap Screw is integral in securing various components within engine systems, ensuring their stability and proper function.

In the cooler system, this screw is used to fasten the cooler to its mounting bracket, ensuring a secure fit that prevents vibrations and maintains the integrity of the cooling process.

Within the engine oil system, the screw plays a role in attaching the engine oil cooler to the engine block or other structural components. This secure attachment is vital for maintaining the cooler’s position and efficiency in dissipating heat from the engine oil.

For the filter components, specifically the full flow oil filter, the screw is employed to connect the filter housing to the engine. This connection is essential for the filter to effectively remove contaminants from the oil, ensuring the engine operates smoothly.

In the lubricating oil system, the screw is utilized in the assembly of the lubricating oil filter (top level assembly) head. It secures the filter head to the filter housing, allowing for a sealed and efficient filtration process that protects the engine’s moving parts.

Similarly, for the lubricating oil filter head and the lubricating oil filter (top level assembly) head, the screw ensures these components are tightly fastened, preventing leaks and ensuring the lubricating oil is effectively filtered before circulating through the engine.

Lastly, in the oil filter cooler head assembly, the screw is critical in attaching the cooler head to the oil filter system. This secure attachment is necessary for the efficient cooling of the oil before it is filtered and circulated, contributing to the overall performance and longevity of the engine.

Conclusion

The Cummins 3092409 Hexagon Flange Head Cap Screw is a vital component in heavy-duty truck and engine applications. Its design and features ensure secure fastening of critical components, contributing to the overall reliability, efficiency, and safety of truck and engine operations. Proper installation, maintenance, and understanding of its role in various engine systems are essential for maximizing its performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.