This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 3089288 and manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this screw to meet the demanding requirements of truck assembly and maintenance. This Cummins part is utilized in various applications where secure fastening is required, ensuring components remain firmly in place under significant stress and vibration.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and flanged base. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from pulling through the material. In mechanical systems, these screws are commonly used for fastening and securing components, offering a balance of strength and ease of installation.

Role in Truck Operation

This part plays a significant role in the operation and maintenance of heavy-duty trucks. It is employed in applications where components need to be securely fastened, such as in the assembly of engine parts, chassis components, and various structural elements. By providing a reliable fastening solution, this screw contributes to the overall integrity and performance of the truck, ensuring that critical components remain in place during operation.

Key Features

The 3089288 boasts several key features that enhance its performance and reliability. Its hexagonal head design allows for straightforward and efficient torque application, while the flange provides additional stability and load distribution. The screw is crafted from high-quality materials, ensuring durability under heavy-duty conditions. These features collectively contribute to the screw’s ability to withstand significant stress and vibration, making it suitable for demanding truck applications.

Benefits

This Cummins part offers several benefits that make it an ideal choice for heavy-duty truck applications. Its design allows for improved torque application, ensuring that components are securely fastened. The flange characteristic provides resistance to loosening, maintaining the integrity of the fastening over time. Additionally, the screw’s durable material properties ensure longevity and reliable performance under demanding conditions.

Installation and Usage

Proper installation of the 3089288 is crucial for ensuring optimal performance. It is recommended to follow torque specifications provided by the manufacturer to achieve the correct fastening tension. Best practices include using the appropriate tools for installation and ensuring that the screw is aligned correctly with the component being fastened. Common applications within truck maintenance and repair include securing engine components, chassis parts, and structural elements.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the 3089288, regular maintenance and troubleshooting are recommended. Common issues such as loosening or corrosion can be addressed by periodically checking the fastening tension and applying appropriate lubricants or coatings. Ensuring that the screw and surrounding components are clean and free from debris will also contribute to its reliable performance.

Cummins Overview

Cummins Inc. is a globally recognized leader in the design, manufacturing, and distribution of diesel and natural gas engines, as well as related technologies. With a rich history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its extensive product range, which includes a variety of components designed to meet the rigorous demands of heavy-duty applications.

Hexagon Flange Head Cap Screw 3089288 in Cummins Engines

The Hexagon Flange Head Cap Screw part number 3089288, manufactured by Cummins, is a critical component in various Cummins engine models. This screw is designed to provide secure fastening in applications where high strength and durability are essential. Its flange head design allows for easy access and tightening with standard tools, making it a practical choice for maintenance and assembly tasks.

Application in Cummins Engines

QSC8.3 CM850 (CM2850)

The 3089288 screw is utilized in the QSC8.3 CM850 (CM2850) engine, where it ensures the secure attachment of various engine components. Its robust construction is well-suited for the demanding conditions within this engine.

QSG12 CM2880 G112, QSG12/X12 CM2350 G110

In the QSG12 CM2880 G112 and QSG12/X12 CM2350 G110 engines, the 3089288 screw is used to fasten parts that require a reliable and tight connection. Its flange head design facilitates efficient assembly and disassembly, crucial for maintaining the engine’s integrity.

QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G, QSK78 CM500

The 3089288 screw is also integral to the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G, and QSK78 CM500 engines. These engines benefit from the screw’s ability to withstand high stress and provide a secure fastening solution for critical engine components.

QSK95 CM2350 K111, QSK95 CM2350 K113

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the 3089288 screw ensures that parts are held firmly in place, contributing to the overall reliability and performance of the engine.

QSM11 CM570

The QSM11 CM570 engine incorporates the 3089288 screw to secure various parts, leveraging its strength and ease of use in maintenance procedures.

QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G

In the QSV81G, QSV91-G4 CM558/CM700 V102, and QSV91G engines, the 3089288 screw is used to fasten components that require a dependable and long-lasting connection.

X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, X13 CM2670 X122B

The X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, and X13 CM2670 X122B engines also utilize the 3089288 screw. This screw’s design is ideal for the specific fastening needs of these engines, ensuring that components are securely held together.

6C8.3, ISG11 CM2880 G108, ISG12 CM2880 G107, ISG12 G CMOH6.0 G111

Finally, the 3089288 screw is used in the 6C8.3, ISG11 CM2880 G108, ISG12 CM2880 G107, and ISG12 G CMOH6.0 G111 engines. Its application in these engines highlights its versatility and effectiveness in providing secure fastening solutions across a range of engine types.

Role of Part 3089288 Hexagon Flange Head Cap Screw in Engine Systems

The part 3089288 Hexagon Flange Head Cap Screw is integral to the assembly and operation of various engine systems. Its primary function is to provide a secure fastening mechanism that ensures components remain firmly in place under operational stress.

Aftercooler and Compressor Systems

In aftercooler and compressor systems, the Hexagon Flange Head Cap Screw is used to attach critical components such as the housing and front gear module. This ensures that the assembly remains intact, allowing for efficient cooling of compressed air and maintaining the structural integrity of the compressor.

Engine Block and Cylinder Assembly

Within the engine block and cylinder assembly, these screws are employed to secure the cylinder to the block. This connection is vital for maintaining the alignment and stability of the cylinder, which is essential for the proper functioning of the engine’s combustion process.

Refrigerant and Cooler Systems

For refrigerant and cooler systems, the Hexagon Flange Head Cap Screw plays a role in attaching the cooler to the refrigerant system. This secure attachment is necessary to prevent leaks and ensure that the cooling process is efficient and reliable.

Oil and Fuel Systems

In oil and fuel systems, these screws are used to fasten components such as the oil pan, fuel pump, and lubricating oil pump. This secure attachment ensures that these components remain in place, allowing for the smooth flow of oil and fuel throughout the engine.

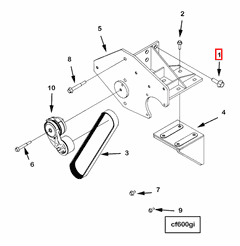

Drive and Barring Systems

For drive and barring systems, the Hexagon Flange Head Cap Screw is utilized to attach the drive components to the engine. This secure connection is essential for the proper rotation and operation of the engine during startup and maintenance procedures.

Mounting and Support Structures

In mounting and support structures, these screws are crucial for attaching the base, rail, and support components to the front engine and power train system. This ensures that the engine is securely mounted and supported, which is vital for the overall stability and performance of the engine.

Auxiliary Cooling and Alarm Systems

Finally, in auxiliary cooling and alarm systems, the Hexagon Flange Head Cap Screw is used to attach the cooler and alarm components to the engine. This secure attachment ensures that these systems function correctly, providing necessary cooling and alerts during engine operation.

Conclusion

The 3089288 Hexagon Flange Head Cap Screw is a critical component in the assembly and maintenance of heavy-duty trucks and Cummins engines. Its design, featuring a hexagonal head and flanged base, provides efficient torque application and enhanced stability. The screw’s robust construction and durable materials ensure reliable performance under demanding conditions, making it an essential part for securing various engine components. Proper installation, regular maintenance, and troubleshooting are key to maximizing the longevity and effectiveness of this part in heavy-duty applications.

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer. Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International. Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy. Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.