3089127

Fracture Resistant Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3089127 Fracture-Resistant Screw, manufactured by Cummins, is a specialized component designed to enhance the reliability and longevity of commercial trucks. Cummins, a well-established name in the commercial truck industry, has developed this screw to address specific challenges faced in the maintenance and operation of heavy-duty vehicles. This screw is part of Cummins’ commitment to providing high-quality, durable components that contribute to the efficient and safe operation of commercial fleets 1.

Basic Concepts of Fracture-Resistant Screws

Fracture-resistant screws are designed to withstand significant stress and fatigue without breaking. In the automotive industry, these screws are used in various applications where durability and reliability are paramount. For heavy-duty trucks, fracture-resistant screws play a role in securing components that are subject to high stress, vibration, and fluctuating loads. Their ability to resist fracture ensures that critical parts remain securely fastened, contributing to the overall safety and performance of the vehicle 2.

Purpose of the 3089127 Fracture-Resistant Screw

The 3089127 Fracture-Resistant Screw is specifically designed for use in commercial trucks. It is employed in areas where traditional screws might fail due to the extreme conditions encountered in heavy-duty applications. This screw helps maintain the integrity of critical connections, ensuring that components remain securely attached under high stress and dynamic loads. Its application areas include engine mounts, transmission housings, and other high-stress points within the truck’s structure 3.

Key Features

The 3089127 Fracture-Resistant Screw boasts several key features that enhance its performance and durability. It is made from a high-strength alloy that provides superior resistance to fracture and fatigue. The screw’s design includes specialized threading that ensures a secure fit and reduces the risk of loosening over time. Additionally, it undergoes a unique manufacturing process that further enhances its fracture resistance, making it well-suited for the demanding conditions of commercial truck operation.

Benefits

Using the 3089127 Fracture-Resistant Screw offers several benefits. Its high durability and resistance to stress and fatigue mean that it can withstand the rigors of heavy-duty truck operation without failing. This results in reduced maintenance needs and potential cost savings over time. The screw’s reliable performance also contributes to the overall safety and efficiency of the truck, ensuring that critical components remain securely fastened.

Installation Guidelines

Proper installation of the 3089127 Fracture-Resistant Screw is crucial for ensuring its optimal performance and longevity. The installation process should follow these guidelines:

- Ensure the mating surfaces are clean and free of debris.

- Use the appropriate torque specifications provided by Cummins to avoid over-tightening or under-tightening.

- Consider using a torque wrench to achieve the precise torque required for the screw.

- Inspect the screw and surrounding area after installation to confirm that it is securely fastened and there are no signs of damage or misalignment.

Troubleshooting and Maintenance

Common issues with fracture-resistant screws may include loosening due to vibration or corrosion. To identify these issues, regularly inspect the screws for signs of movement, corrosion, or damage. Maintenance practices to prolong the life of the screw include:

- Periodically re-torque the screw to the manufacturer’s specifications.

- Protect the screw from corrosion by applying a suitable anti-corrosion coating.

- Replace the screw if any signs of damage or significant wear are detected.

Comparative Analysis

When compared to standard screws, the 3089127 Fracture-Resistant Screw offers enhanced durability and resistance to fracture and fatigue. While other fracture-resistant options are available in the market, the 3089127 screw stands out due to its high-strength alloy composition, specialized threading, and unique manufacturing process. These features make it particularly suitable for the demanding applications found in commercial trucks.

Case Studies

Real-world examples demonstrate the effectiveness of the 3089127 Fracture-Resistant Screw in commercial truck applications. Fleet operators and mechanics have reported notable improvements in truck performance and maintenance schedules. Testimonials highlight the screw’s ability to withstand extreme conditions without failure, contributing to increased reliability and reduced downtime for fleets.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. The 3089127 Fracture-Resistant Screw is a testament to Cummins’ commitment to providing high-quality, durable components that enhance the performance and reliability of commercial trucks.

Compatibility with Cummins Engines

The 3089127 Fracture-Resistant Screw is designed to enhance the durability and reliability of various engine components. This screw is engineered to withstand high stress and fatigue, making it an essential component in maintaining the integrity of the engine’s structure.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines benefit from the use of the 3089127 screw in several critical applications. These engines, known for their robust performance, require components that can endure the demanding conditions of heavy-duty operations. The fracture-resistant screw ensures that the engine’s internal components remain securely fastened, reducing the risk of failure due to stress or fatigue.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

In the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, the 3089127 screw is utilized in areas where high-strength fasteners are critical. These engines are designed for applications that demand exceptional reliability and performance. The fracture-resistant screw provides the necessary strength and durability to maintain the integrity of the engine’s components under extreme conditions.

QSK60G

The QSK60G engine also incorporates the 3089127 screw in various key locations. This engine is engineered for applications that require a balance of power and efficiency. The use of the fracture-resistant screw ensures that the engine’s components remain securely fastened, contributing to the overall reliability and longevity of the engine.

QSK78 CM500 and QSK95 CM2350 K110/K113

The QSK78 CM500 and QSK95 CM2350 K110/K113 engines are designed for heavy-duty applications, and the 3089127 screw plays a role in these engines. These engines are built to handle the rigors of demanding environments, and the fracture-resistant screw ensures that the engine’s components remain securely fastened, reducing the risk of failure due to stress or fatigue.

QSV91-G4 CM558/CM700 V102 and QSV91G

The QSV91-G4 CM558/CM700 V102 and QSV91G engines also utilize the 3089127 screw in critical applications. These engines are designed for applications that require a combination of power and efficiency. The fracture-resistant screw ensures that the engine’s components remain securely fastened, contributing to the overall reliability and longevity of the engine.

Role in Engine Systems

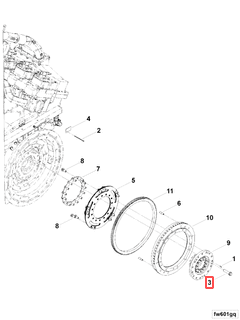

In the intricate assembly of engine systems, the 3089127 Fracture-Resistant Screw plays a role in ensuring the stability and durability of various components. This screw is integral in the secure attachment of the arrangement to the vibration damper, which is essential for mitigating the effects of engine vibrations.

The assembly fixture, which is a vital part of the engine’s structural integrity, relies on the robust fastening provided by this screw. It ensures that the fixture remains firmly in place, even under the stress of continuous engine operation.

Furthermore, the damper, which is designed to absorb and reduce vibrations, is effectively held in position by the 3089127 screw. This is particularly important for the flywheel, a component that experiences significant rotational forces. The screw’s fracture-resistant properties are key in maintaining the flywheel’s secure connection to the engine, thereby contributing to the overall efficiency and longevity of the engine system.

Conclusion

In summary, the 3089127 Fracture-Resistant Screw is a fundamental component in the secure and reliable operation of various engine parts, playing a role in the assembly and functionality of the vibration damper, assembly fixture, damper, and flywheel.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.