3082427

Fracture Resistant Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Fracture Resistant Screw, part number 3082427, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins is recognized for producing high-quality parts that enhance the performance and reliability of commercial vehicles. This screw is significant due to its role in ensuring the structural integrity and longevity of various truck components.

Purpose and Function

The Fracture Resistant Screw, part number 3082427, plays a role in securing and maintaining the alignment of components within commercial trucks. It is utilized in various truck systems, including the engine, transmission, and chassis. By providing a secure fastening solution, this screw helps in maintaining the operational efficiency and safety of the vehicle. Its application extends to critical areas where vibration and stress are common, ensuring that components remain firmly in place under demanding conditions 1.

Key Features

The Fracture Resistant Screw is characterized by several key attributes that enhance its performance. It is made from a high-strength alloy, which provides superior resistance to fracture under stress. The design includes features such as a hexagonal socket for easy installation and removal, and a threaded shank that ensures a tight and secure fit. Additionally, the screw undergoes a unique manufacturing process that includes heat treatment to further increase its durability and resistance to corrosion 2.

Benefits

Using the Fracture Resistant Screw in truck maintenance and operation offers several advantages. Its high strength and fracture resistance contribute to improved durability, reducing the likelihood of failure under stress. This results in reduced maintenance frequency, as the screw is less likely to require replacement due to breakage. Enhanced safety is another benefit, as the secure fastening provided by this screw helps prevent component misalignment or detachment, which could lead to hazardous situations on the road 3.

Installation and Usage

Proper installation of the Fracture Resistant Screw is vital to ensure its effectiveness. It is recommended to use a torque wrench to achieve the correct tightening specification, which varies depending on the application. Specific tools, such as a socket driver compatible with the screw’s hexagonal socket, may be required for installation. The screw is applicable to a wide range of truck models and components, making it a versatile choice for maintenance and repair tasks 4.

Troubleshooting and Maintenance

Identifying common issues with the Fracture Resistant Screw, such as loosening or corrosion, is important for maintaining truck performance. Regular inspections during maintenance checks can help detect these issues early. To prolong the lifespan of the screw, it is advisable to protect it from exposure to corrosive substances and to ensure it is tightened to the manufacturer’s specified torque. In cases where replacement or repair is necessary, following the correct procedures will help maintain the integrity of the fastening and the overall system.

Manufacturer - Cummins

Cummins is a reputable manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance parts, Cummins has established a strong reputation among truck operators and maintenance professionals. The company’s portfolio includes a wide range of products designed to enhance the efficiency, reliability, and safety of commercial vehicles.

Cummins Fracture Resistant Screw 3082427 Compatibility

The Cummins Fracture Resistant Screw, part number 3082427, is designed to enhance the reliability and durability of various engine models. This component is particularly crucial in maintaining the structural integrity of the engines, ensuring that they can withstand the rigors of continuous operation.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines benefit from the use of the 3082427 screw in several critical applications. These engines, known for their robust performance, require components that can endure high stress and frequent operational cycles. The fracture-resistant screw is integral in securing various parts within the engine, providing a fail-safe mechanism that prevents catastrophic failures due to screw fracture.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

In the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, the 3082427 screw plays a pivotal role in maintaining the integrity of the engine’s internal components. These engines are designed for heavy-duty applications, and the fracture-resistant screw ensures that the engine can operate under extreme conditions without compromising on safety or performance.

QSK60G

The QSK60G engine also relies on the 3082427 screw for critical fastening applications. This engine model is engineered for high-performance and durability, and the fracture-resistant screw is a key component in achieving these goals. By preventing screw failure, this part contributes to the overall reliability and longevity of the engine.

QSK78 CM500 and QSK95 CM2350 K110/K113

The QSK78 CM500 and QSK95 CM2350 K110/K113 engines are designed for demanding industrial applications. The 3082427 screw is used in these engines to secure components that are subjected to significant mechanical stress. Its fracture-resistant properties ensure that the engine can maintain its operational integrity, even in the most challenging environments.

Role of Part 3082427 Fracture Resistant Screw in Engine Systems

In the intricate assembly of engine systems, the 3082427 Fracture Resistant Screw plays a significant role in ensuring the stability and integrity of various components. This screw is instrumental in securing the Air Compressor Bracket, which supports the Air Compressor Kit. The secure attachment of these components is essential for the efficient operation of the air compressor, which in turn supports the engine’s cooling and lubrication systems.

Moving to the core of the engine, the 3082427 screw is used in the assembly of the Block and Cylinder. These components are the heart of the engine, where combustion occurs, and power is generated. The screw ensures that these parts remain aligned and intact under the high pressures and temperatures of engine operation.

In the valve train mechanism, the 3082427 screw is employed to fasten the Cam Follower Lever. This lever is a pivotal part of the valve actuation system, controlling the opening and closing of the engine’s valves in sync with the piston’s movement.

The screw also finds its application in the Crankshaft and Bearings assembly. Here, it helps in maintaining the precise alignment and secure fitting of the crankshaft within the engine block, which is vital for the smooth rotation and balance of the crankshaft.

In the Cylinder Block, the 3082427 screw is used to secure various internal components, ensuring that the block remains a solid, unified structure capable of withstanding the forces generated during engine operation.

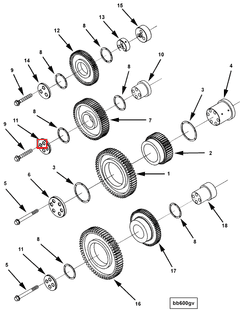

The Gear Housing and Front Gear are other areas where this screw is utilized. In these components, the screw ensures that the gears are held in place with the required precision, allowing for the efficient transfer of power from the crankshaft to other parts of the engine.

Lastly, in the Housing components, the 3082427 screw plays a role in securing various housings that encase moving parts, protecting them and ensuring their proper function.

Overall, the 3082427 Fracture Resistant Screw is a key element in the assembly and operation of these engine components, contributing to the overall reliability and performance of the engine system.

Conclusion

The Cummins Fracture Resistant Screw, part number 3082427, is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its high-strength design, resistance to fracture, and secure fastening capabilities contribute to the durability, safety, and efficiency of the vehicles it is used in. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing the benefits of this part.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Wharton, A. J. Diesel Engines. Butterworth-Heinemann Ltd, 1991.

↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.