This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Socket Head Cap Screw, specifically Part #3073999 by Cummins, is a vital component in the maintenance and operation of commercial trucks. Cummins, a well-established manufacturer in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications. This screw is designed to provide reliable fastening solutions, ensuring the integrity and efficiency of truck components.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for easy installation and removal using a hex key. These screws are widely used in the automotive industry for their strength, precision fit, and resistance to loosening. They function by securely joining components together, distributing load evenly, and maintaining structural integrity under various conditions 1.

Purpose of the 3073999 Socket Head Cap Screw in Truck Operation

The 3073999 Socket Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in applications where high strength and resistance to vibration are required. This screw helps in securing critical components, ensuring they remain firmly in place during operation, thereby contributing to the overall safety and performance of the truck.

Key Features of the 3073999 Socket Head Cap Screw

The 3073999 Socket Head Cap Screw is distinguished by several key features. Its design includes a hexagonal socket head, which allows for efficient tightening and loosening using a hex key. The screw is made from high-quality materials, ensuring durability and resistance to corrosion. Additionally, it features a fully threaded design, providing a strong and secure fastening solution.

Benefits of Using the 3073999 Socket Head Cap Screw

Utilizing the 3073999 Socket Head Cap Screw offers several advantages. Its durable construction ensures long-lasting performance, even under demanding conditions. The ease of installation, thanks to the hexagonal socket, reduces the time required for maintenance tasks. Furthermore, its resistance to wear and tear contributes to the overall reliability of the truck’s components.

Installation and Usage Guidelines

To ensure optimal performance and longevity, the 3073999 Socket Head Cap Screw should be installed following specific guidelines. Begin by cleaning the installation area to remove any debris or contaminants. Use a hex key to insert and tighten the screw, ensuring it is securely fastened without over-tightening, which could damage the threads. Regularly inspect the screw for signs of wear or loosening to maintain its effectiveness.

Troubleshooting Common Issues

Frequent problems associated with Socket Head Cap Screws include loosening due to vibration and corrosion. To address these issues, ensure the screw is properly tightened during installation and consider using a thread locker for added security. Regularly inspect the screw and surrounding components for signs of corrosion, and apply a suitable protective coating if necessary.

Maintenance Tips

Regular maintenance of the 3073999 Socket Head Cap Screw is essential to prolong its service life and maintain truck efficiency. Periodically check the screw for signs of wear, corrosion, or loosening. Clean the installation area regularly to prevent the buildup of debris, which can affect the screw’s performance. Replace the screw if it shows significant wear or damage to ensure continued reliability.

Safety Considerations

When handling and installing the 3073999 Socket Head Cap Screw, it is important to observe several safety practices. Use the appropriate tools to avoid damaging the screw or the surrounding components. Wear protective gear, such as gloves and safety glasses, to prevent injuries. Ensure the truck is securely parked and the engine is off during installation to prevent accidents.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications 2.

Socket Head Cap Screw 3073999 in Cummins Engines

The Socket Head Cap Screw part number 3073999, manufactured by Cummins, is a critical component used in various Cummins engine models. This part is integral in securing and stabilizing different engine components, ensuring the engine operates efficiently and reliably.

6B5.9

In the 6B5.9 engine, the 3073999 screw is utilized in several key areas, including the attachment of engine mounts and securing the cylinder head to the engine block. Its design ensures a tight and secure fit, which is essential for maintaining engine integrity under high stress and vibration conditions.

K19, K38, K50

The K19, K38, and K50 engines also incorporate the 3073999 Socket Head Cap Screw in their construction. These engines, known for their robust performance, use this screw to fasten various parts such as the intake manifold, exhaust manifold, and other critical assemblies. The screw’s precision and strength are vital for these engines, which often operate in demanding environments.

M11 CELECT PLUS, M11 MECHANICAL

For the M11 CELECT PLUS and M11 MECHANICAL engines, the 3073999 screw plays a crucial role in securing the engine’s electronic control module (ECM) and other sensitive components. Its use in these engines highlights its importance in maintaining the delicate balance between electronic and mechanical systems.

N14 MECHANICAL

In the N14 MECHANICAL engine, the 3073999 screw is employed in fastening the turbocharger and other high-stress components. The durability and reliability of this screw are essential for the engine’s performance, especially in heavy-duty applications.

NH/NT 855

The NH/NT 855 engines also benefit from the use of the 3073999 Socket Head Cap Screw. This part is used in securing various engine components, ensuring that the engine maintains its structural integrity and operational efficiency. The screw’s precision and strength are critical for the reliable performance of these engines.

Each of these engines relies on the 3073999 Socket Head Cap Screw for its structural and operational integrity, demonstrating the importance of this component in Cummins’ engine designs.

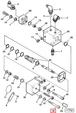

Role of Part 3073999 Socket Head Cap Screw in Various Engine Components

The part 3073999 Socket Head Cap Screw is integral to the assembly and functionality of several key engine components. Its application spans across various parts, ensuring secure fastening and reliable operation.

Aftercooler Core

In the aftercooler core, the Socket Head Cap Screw is used to secure the core to its mounting bracket. This ensures that the core remains stable during operation, allowing for efficient cooling of the compressed air before it enters the engine.

Base Parts

For base parts, the Socket Head Cap Screw plays a role in attaching the base to the engine block. This secure attachment is vital for the structural integrity of the engine, providing a stable foundation for other components.

Cam Follower Housing

Within the cam follower housing, the Socket Head Cap Screw is employed to fasten the housing to the engine block. This secures the housing in place, allowing for smooth operation of the cam followers and reducing wear on the camshaft.

Camshaft and Gear

The Socket Head Cap Screw is utilized in the assembly of the camshaft and gear. It ensures that the camshaft is properly aligned and secured, which is essential for the precise timing of valve operations.

Check Valve

In the check valve assembly, the Socket Head Cap Screw is used to secure the valve in place. This ensures that the valve functions correctly, allowing fluid to flow in one direction while preventing backflow.

Connecting Rod and Piston

For the connecting rod and piston assembly, the Socket Head Cap Screw is crucial in securing the components together. This ensures that the piston moves smoothly within the cylinder, contributing to the engine’s overall efficiency.

Cylinder Head

The Socket Head Cap Screw is used in the cylinder head to secure various components, such as the valve cover and intake manifold. This ensures a tight seal, preventing leaks and maintaining optimal combustion conditions.

EBM: Performance Parts

In EBM performance parts, the Socket Head Cap Screw is used to secure upgraded components, such as high-performance cams or valve springs. This ensures that these parts are firmly in place, allowing for enhanced engine performance.

Hydro Mechanical Step

For the hydro mechanical step, the Socket Head Cap Screw is used to secure the step mechanism. This ensures that the step functions correctly, contributing to the overall efficiency of the engine’s variable valve timing system.

Injector

In the injector assembly, the Socket Head Cap Screw is used to secure the injector to the engine block. This ensures that the injector is properly aligned, allowing for precise fuel delivery.

Oil Control (Top Level Assembly) Valve

The Socket Head Cap Screw is utilized in the oil control top level assembly valve to secure the valve in place. This ensures that the valve operates correctly, managing oil flow to various engine components.

Oil Manifold

In the oil manifold, the Socket Head Cap Screw is used to secure the manifold to the engine block. This ensures that the manifold is properly aligned, allowing for efficient distribution of oil throughout the engine.

Performance Parts

For various performance parts, the Socket Head Cap Screw is used to secure upgraded components, such as turbochargers or intercoolers. This ensures that these parts are firmly in place, allowing for enhanced engine performance.

Protective Cover

The Socket Head Cap Screw is used to secure the protective cover in place. This ensures that the cover remains in position, protecting sensitive engine components from damage.

Step Oil Control Valve

In the step oil control valve, the Socket Head Cap Screw is used to secure the valve in place. This ensures that the valve operates correctly, managing oil flow to the variable valve timing system.

Step White Smoke Kit

For the step white smoke kit, the Socket Head Cap Screw is used to secure the kit components. This ensures that the kit functions correctly, reducing white smoke emissions from the engine.

Timing Control Valve

The Socket Head Cap Screw is utilized in the timing control valve to secure the valve in place. This ensures that the valve operates correctly, contributing to the precise timing of engine operations.

Viscosity Sensor

In the viscosity sensor assembly, the Socket Head Cap Screw is used to secure the sensor in place. This ensures that the sensor functions correctly, providing accurate readings of oil viscosity for optimal engine performance.

Conclusion

The 3073999 Socket Head Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks and various Cummins engine models. Its robust design, ease of installation, and resistance to wear and corrosion make it an essential part for ensuring the reliability and efficiency of truck and engine components. Regular maintenance and proper installation practices are crucial to maximize the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.