This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

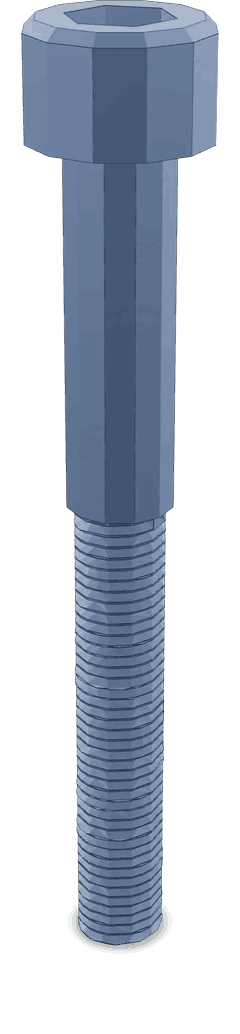

The Socket Head Cap Screw Part #3071940, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces this screw to meet the demanding requirements of heavy-duty applications. This screw is integral to various truck systems, ensuring secure and reliable fastening of components.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. These screws are commonly used in mechanical applications where high strength and precision are required. They function by providing a strong, permanent connection between components, distributing load evenly and resisting loosening over time 1.

Purpose of the 3071940 Socket Head Cap Screw in Truck Operation

The 3071940 Socket Head Cap Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck systems, including engine components, transmission assemblies, and chassis structures. This screw ensures that critical parts remain securely fastened, contributing to the overall stability and performance of the vehicle. Its application in these systems highlights its importance in maintaining the integrity and functionality of the truck 2.

Key Features

The 3071940 Socket Head Cap Screw boasts several key features that enhance its performance in heavy-duty applications. Its design includes a robust hexagonal socket head, which allows for precise and efficient tightening. The screw is composed of high-strength materials, ensuring durability under demanding conditions. Additionally, it may feature unique attributes such as corrosion-resistant coatings or specialized threading to improve grip and reliability.

Benefits

Using the 3071940 Socket Head Cap Screw offers several benefits. It provides improved reliability in fastening applications, ensuring that components remain securely attached under various operating conditions. The screw’s design facilitates ease of installation, reducing the time and effort required during maintenance procedures. Furthermore, its resistance to wear and corrosion enhances the longevity of the fastener, contributing to the overall durability of the truck 3.

Installation Guidelines

Proper installation of the 3071940 Socket Head Cap Screw is crucial for optimal performance. To install, use a hex key to drive the screw into the designated location. It is recommended to follow specific torque settings provided by the manufacturer to ensure the screw is tightened to the appropriate level without over-tightening, which could damage the screw or the surrounding components. Special considerations may include using thread lockers or anti-seize compounds to enhance performance and prevent loosening.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws may include loosening, corrosion, or damage from wear. Regular inspection and maintenance can help identify these issues early. Signs of wear or damage, such as stripped threads or a weakened head, may indicate the need for replacement. Proper maintenance, including cleaning and applying protective coatings, can prolong the lifespan of the screw and ensure continued reliable performance.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality products and innovative solutions. With a rich history of providing reliable and efficient components, Cummins has established a strong reputation for excellence. The company’s product range includes engines, transmissions, and various aftermarket parts, all designed to meet the rigorous demands of commercial trucking. The 3071940 Socket Head Cap Screw is a testament to Cummins’ commitment to quality and reliability in heavy-duty applications.

Socket Head Cap Screw 3071940 in Cummins Engines

The Socket Head Cap Screw 3071940, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to provide secure fastening in high-stress environments, ensuring the integrity and performance of the engine.

QSK19 CM850 MCRS and QSK60 CM850 MCRS

In the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines, the Socket Head Cap Screw 3071940 is used to secure various components, including engine mounts and brackets. Its design allows for precise torque application, which is essential for maintaining the alignment and stability of these components under operational stress.

QSK50 CM2150 K107 and QSK50 CM2150 MCRS

For the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, the Socket Head Cap Screw 3071940 plays a crucial role in fastening internal components. This includes securing parts of the engine block and other critical assemblies. The screw’s robust construction ensures that these components remain tightly fastened, even under the high pressures and temperatures typical of these engines.

VTA903 CM2250 V105

In the VTA903 CM2250 V105 engine, the Socket Head Cap Screw 3071940 is utilized to secure various engine components, including those related to the exhaust system and other critical assemblies. Its design provides the necessary strength and durability to withstand the operational stresses of this engine model.

Each of these engines benefits from the use of the Socket Head Cap Screw 3071940, ensuring that all fastened components remain securely in place, contributing to the overall reliability and performance of the engine.

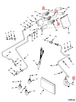

Role of Part 3071940 Socket Head Cap Screw in Various Engine Systems

The 3071940 Socket Head Cap Screw is a versatile fastener utilized across multiple engine systems to ensure secure and reliable connections. Its application spans various components, contributing to the overall functionality and safety of the engine.

Accessories

In the realm of engine accessories, the 3071940 Socket Head Cap Screw is often employed to mount and secure components such as the electric starting system. This ensures that the starting mechanism is firmly attached, reducing the risk of detachment during operation.

Fuel System

Within the fuel system, this screw plays a significant role in securing fuel lines and connectors. Its precise threading and robust design help maintain the integrity of fuel delivery, preventing leaks and ensuring consistent fuel flow to the engine.

Starting Aids

For starting aids like the air heater starting aid and injection starting aid, the 3071940 Socket Head Cap Screw is used to attach critical components. This includes securing the hotstart start kit and ensuring that the pressure relief valve is correctly installed, which is essential for safe and efficient engine start-up.

Alarm Systems

In alarm systems, particularly those integrated with dump valve assemblies and dump valve kits, this screw is utilized to secure sensor brackets and other critical components. This ensures that the alarm system functions correctly, providing timely warnings in case of malfunctions.

Engine Monitoring Systems

The 3071940 Socket Head Cap Screw is also integral in engine monitoring systems. It is used to attach various sensors and brackets that monitor engine performance. This includes securing components that measure pressure, temperature, and other vital parameters, ensuring accurate data collection and system reliability.

Overall, the 3071940 Socket Head Cap Screw is a fundamental component in maintaining the structural integrity and operational efficiency of various engine systems. Its reliable performance across different applications underscores its importance in engine design and maintenance.

Conclusion

The 3071940 Socket Head Cap Screw is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its robust design, high-strength materials, and precise threading ensure secure and reliable fastening of critical components across various engine systems. Proper installation and maintenance of this screw are essential for the overall stability, performance, and longevity of the vehicle.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.