3070131

Socket Head Cap Screw

Cummins®

IN STOCK

5 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3070131 Socket Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this screw to meet the rigorous demands of truck operation and maintenance. This part is integral to various components within commercial trucks, ensuring secure and reliable fastening solutions.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for torque application using a hex key. They are widely used in mechanical applications due to their strength, precision fit, and ease of installation. These screws function by providing a secure connection between parts, distributing load evenly, and resisting loosening under vibration and dynamic loads 1.

Purpose of Socket Head Cap Screw 3070131 in Truck Operation

The 3070131 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in areas where high strength and resistance to loosening are required. This screw helps in securing critical components, ensuring that parts remain firmly in place under the demanding conditions of truck operation. Its application contributes to the overall reliability and safety of the vehicle.

Key Features

The 3070131 is distinguished by several key features. Its design includes a hexagonal socket head, which allows for efficient torque application and reduces the risk of cam-out during tightening. The screw is made from high-quality materials, ensuring durability and resistance to corrosion. Additionally, it may feature a unique thread profile or coating that enhances its functionality in specific applications.

Benefits of Using Socket Head Cap Screw 3070131

Employing the 3070131 in truck maintenance and assembly offers several advantages. Its high strength and resistance to loosening make it suitable for applications where vibrations and dynamic loads are present. The ease of installation, thanks to its hexagonal socket, allows for quick and efficient fastening. Moreover, its reliability and durability contribute to the longevity of the truck’s components.

Installation Guidelines

Proper installation of the 3070131 involves several steps. Begin by ensuring the mating surfaces are clean and free of debris. Use a hex key of the appropriate size to drive the screw into the pre-drilled hole. Apply steady, even pressure to avoid cross-threading. Tighten the screw to the manufacturer’s specified torque setting to ensure a secure fit without over-tightening, which could damage the screw or the component.

Troubleshooting Common Issues

Frequent problems with Socket Head Cap Screws can include loosening, corrosion, or damage. Loosening may occur due to insufficient torque during installation or dynamic loads during operation. To address this, re-tighten the screw to the specified torque and consider using a thread locker. Corrosion can be mitigated by selecting screws with a corrosion-resistant coating. Damaged screws should be replaced to maintain the integrity of the fastening 2.

Maintenance Tips

Regular maintenance of Socket Head Cap Screws involves periodic inspection for signs of loosening, corrosion, or damage. Screws should be re-tightened as necessary and replaced if they show signs of wear or failure. Keeping the mating surfaces clean and free of contaminants will also contribute to the longevity and optimal performance of the screws.

Safety Considerations

When working with Socket Head Cap Screws, it is important to observe several safety practices. Use personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that tools are in good condition and appropriate for the task. Follow all manufacturer guidelines for torque settings and installation procedures to avoid damage to the screw or the component being fastened.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Socket Head Cap Screw 3070131 in Cummins Engines

The 3070131, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of these engines, ensuring proper fastening and structural integrity.

X12 CM2350 and X119B Engines

In the X12 CM2350 and X119B engines, the 3070131 is used in several key areas. It is typically employed in securing engine components, such as the cylinder head, to the engine block. This ensures that the engine operates smoothly and efficiently by maintaining the correct alignment and pressure between these parts.

Common Applications

- Cylinder Head Fastening: The screw is often used to fasten the cylinder head to the engine block, ensuring a tight seal and preventing leaks.

- Engine Block Assembly: It is also used in various points of the engine block assembly, securing different parts together to maintain the engine’s structural integrity.

- Accessory Mounting: The screw can be found in mounting points for engine accessories, ensuring these components are securely attached and properly aligned.

Importance of the Socket Head Cap Screw

The 3070131 is crucial for the longevity and performance of the engines. Its design allows for easy installation and removal, which is essential during maintenance and repair processes. The screw’s material and construction ensure it can withstand the high stresses and temperatures typical in engine environments.

Role of Part 3070131 Socket Head Cap Screw in Engine Systems

The 3070131 is integral in securing various components within engine systems, ensuring optimal performance and reliability.

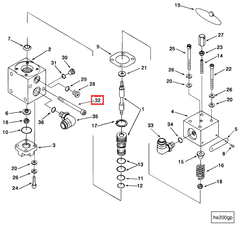

In fuel injection systems, this screw is often used to fasten injector components, providing a secure connection that withstands the high pressures and temperatures within the system. Its precise fit and strong holding power are essential for maintaining the integrity of the injector assembly, which directly influences fuel delivery and engine performance.

Within fuel pumps, the Socket Head Cap Screw plays a significant role in attaching critical parts such as the pump housing or internal components. This ensures that the pump operates efficiently, delivering the necessary fuel pressure to the engine. The screw’s design allows for easy adjustment and maintenance, which is vital for the longevity and performance of the fuel pump.

In performance parts, such as high-flow fuel systems or aftermarket injectors, the Socket Head Cap Screw is used to secure enhancements that improve engine efficiency and power output. Its reliability under stress is key to maintaining the performance gains these parts offer.

Overall, the 3070131 is a fundamental component in ensuring that engine systems operate smoothly and efficiently, contributing to the overall performance and durability of the engine 3.

Conclusion

The 3070131 Socket Head Cap Screw by Cummins is a vital component in the maintenance and operation of commercial trucks and engines. Its design, featuring a hexagonal socket head, allows for efficient torque application and reduces the risk of cam-out during tightening. Made from high-quality materials, this screw ensures durability and resistance to corrosion, making it suitable for applications under high stress and dynamic loads. Proper installation, regular maintenance, and adherence to safety practices are essential to maximize the screw’s performance and longevity. Cummins’ reputation for producing reliable, high-performance components is upheld by the 3070131, which plays a critical role in securing various engine components, ensuring optimal performance and reliability.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016)

↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety (SAE International, 2023)

↩ -

Angelina Eret, Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves (Springer Nature, 2024)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.