3069113

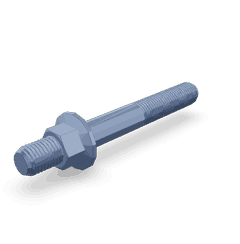

Studded Flange Cap Screw

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Studded flange cap screws are critical components in the assembly and maintenance of commercial trucks. They offer secure fastening solutions that are essential for the integrity and performance of various truck systems. This discussion focuses on the 3069113 studded flange cap screw by Cummins, highlighting its importance in heavy-duty applications.

Basic Concepts

A studded flange cap screw is a type of fastener that includes a threaded stud and a flanged head. The stud extends beyond the nut, allowing for additional components to be attached or aligned. The flange provides a broad surface area that enhances the screw’s resistance to rotation and loosening. In a truck’s mechanical system, these screws are used to secure components that require a high degree of stability and resistance to vibration 1.

Purpose and Function

The 3069113 studded flange cap screw by Cummins is designed for specific applications within a truck’s operational systems. It is used in areas where secure fastening is required to maintain the structural integrity and alignment of components. This screw supports systems that are subject to significant stress and vibration, ensuring that parts remain firmly in place under demanding conditions 2.

Key Features

The 3069113 studded flange cap screw is constructed from high-quality materials that offer durability and resistance to corrosion. It features a specific threading type that ensures a tight and secure fit, reducing the risk of loosening over time. The flange design provides additional surface area for torque application, enhancing the screw’s ability to withstand rotational forces. Unique attributes of this screw may include specialized coatings or treatments that further improve its performance and longevity 3.

Benefits

Using the 3069113 studded flange cap screw offers several advantages. It provides improved fastening security, which is crucial in applications where components are exposed to high levels of stress and vibration. The design of the screw also facilitates ease of installation and removal, which is beneficial during maintenance procedures. Additionally, its resistance to vibration helps maintain the integrity of the fastened components over time.

Troubleshooting and Maintenance

Common issues with studded flange cap screws may include loosening due to vibration or corrosion. To address these problems, regular inspections and tightening may be necessary. Maintenance practices should include checking for signs of wear or damage and replacing screws as needed to ensure continued reliable performance. Proper torque settings during installation are also important to prevent over-tightening, which can lead to screw failure.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins serves a wide range of industries, including commercial trucking. The company is committed to providing reliable and efficient solutions that meet the demanding requirements of its customers.

Compatibility with Cummins Engines

The 3069113 studded flange cap screw is engineered to fit seamlessly with several Cummins engine models, ensuring robust and reliable performance. Here is a detailed look at its compatibility with the specified engines:

N14 CELECT and N14 CELECT PLUS Engines

The 3069113 screw is specifically designed to integrate with the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their advanced electronic controls and high performance. The screw’s design allows for precise and secure fastening of flanges, which is essential for maintaining the integrity of the engine’s cooling and exhaust systems.

N14 MECHANICAL Engine

Similar to the CELECT variants, the N14 MECHANICAL engine also benefits from the use of the 3069113 screw. This engine model relies on mechanical controls and offers a robust solution for heavy-duty applications. The screw’s studded feature provides additional grip and stability, which is crucial for withstanding the mechanical stresses encountered in these engines.

NH/NT 855 Engines

The NH/NT 855 engines are another series where the 3069113 screw proves to be an indispensable component. These engines are designed for versatility and efficiency, often used in agricultural and construction machinery. The screw’s design ensures that flanges are securely fastened, contributing to the overall reliability and durability of the engine.

Role of 3069113 Studded Flange Cap Screw in Engine Systems

The 3069113 studded flange cap screw is instrumental in securing various components within engine systems, ensuring stability and integrity during operation.

Mounting Applications

In mounting applications, this screw is utilized to fasten components securely to the engine block or chassis. It plays a significant role in the assembly of the oil pan, providing a robust connection that withstands the vibrations and stresses encountered during engine operation.

Oil Pan Assembly

Within the oil pan assembly, the 3069113 screw is employed to attach the oil pan to the engine block. This connection is vital for maintaining the structural integrity of the oil pan, which houses the engine’s lubricant. The screw ensures that the oil pan remains firmly in place, preventing oil leaks and ensuring efficient lubrication of engine components.

Noise Reduction Components

In noise reduction applications, such as noise mounting panels, the 3069113 screw helps in securing these panels to the engine or chassis. This is essential for reducing engine noise and vibrations, contributing to a quieter and more comfortable driving experience. The screw’s design allows for a tight and secure fit, which is necessary for the effective functioning of noise reduction components.

Oil Mounting Pans

For oil mounting pans, the 3069113 screw is used to attach the pan to the engine or other supporting structures. This ensures that the pan remains in the correct position, facilitating proper oil flow and distribution within the engine. The secure attachment provided by the screw is essential for the pan’s durability and performance.

General Pan and Panel Attachments

Across various pan and panel attachments, the 3069113 screw offers a reliable solution for securing these components. Whether it’s an oil pan, noise mounting panel, or other similar components, the screw’s studded flange design provides enhanced grip and stability, ensuring that these parts remain firmly in place under operational conditions.

Conclusion

The 3069113 studded flange cap screw by Cummins is a versatile and essential component for various Cummins engine models. Its design ensures secure fastening of flanges, which is critical for maintaining the performance and longevity of these engines. The screw’s high-quality construction, resistance to corrosion, and specialized features make it a reliable choice for heavy-duty applications.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.