This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

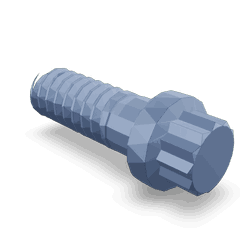

The Twelve Point Cap Screw (Part #3065485) manufactured by Cummins is a specialized fastener designed for commercial truck applications. It plays a significant role in ensuring the structural integrity and performance of truck components. This screw is engineered to withstand the demanding conditions encountered in heavy-duty truck operations, providing reliable fastening solutions that contribute to the overall efficiency and safety of the vehicle 1.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener that features a hexagonal socket with twelve sides instead of the standard six. This design allows for greater torque application and reduces the risk of cam-out, which occurs when the fastener twists in the socket during tightening. The twelve-point design provides a more secure fit and allows for higher torque without damaging the screw head 2. In fastening applications, these screws are used to join components securely, ensuring that they remain fixed under various operational stresses.

Purpose and Role in Truck Operation

The Twelve Point Cap Screw (Part #3065485) serves a specific purpose in commercial trucks by securing critical components that are subject to significant stress and vibration. It contributes to the overall functionality and reliability of truck components by providing a strong and durable fastening solution. This screw is often used in applications where high torque is required, and where the risk of loosening due to vibration is a concern. Its role is vital in maintaining the structural integrity of the truck, ensuring that components remain securely fastened during operation 3.

Key Features

The Twelve Point Cap Screw (Part #3065485) boasts several key features that enhance its performance in heavy-duty applications. Its design includes a twelve-sided socket head, which allows for better torque application and reduced cam-out risk. The screw is made from high-strength materials, typically alloy steel, to ensure durability under demanding conditions. It features a coarse thread type, which provides excellent holding power in various materials. Additionally, the screw may have a zinc-plated or other protective coating to enhance corrosion resistance, making it suitable for use in harsh environments 4.

Benefits

The Twelve Point Cap Screw (Part #3065485) offers several benefits that make it an ideal choice for commercial truck applications. Its design allows for improved torque application, ensuring that components are securely fastened. The reduced risk of cam-out enhances the reliability of the fastening process. The high-strength material composition ensures enhanced durability, even under extreme conditions. Furthermore, the screw’s compatibility with various truck components makes it a versatile fastening solution. The protective coating provides added resistance to corrosion, prolonging the lifespan of the screw in demanding environments 5.

Installation Guidelines

Proper installation of the Twelve Point Cap Screw (Part #3065485) is crucial to ensure secure and reliable fastening. Begin by selecting the appropriate size and type of screw for the application. Use a torque wrench to apply the recommended torque specifications, which can be found in the manufacturer’s guidelines. Ensure that the screw is aligned properly with the mating component to avoid cross-threading. It is recommended to use a socket wrench designed for twelve-point screws to prevent damage to the screw head. Follow best practices by inspecting the installation for proper torque and alignment to ensure a secure fastening 6.

Troubleshooting and Maintenance

Common issues with Twelve Point Cap Screws in truck applications may include loosening due to vibration, corrosion, or damage to the screw head. To troubleshoot these issues, inspect the screw and mating components for signs of wear or corrosion. If loosening is detected, re-tighten the screw to the recommended torque specifications. In cases of corrosion, consider replacing the screw with a new one to ensure continued performance. Regular maintenance practices, such as periodic inspection and re-torquing, can help prolong the lifespan of the screws and ensure optimal performance 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality components for commercial vehicles. The company’s history of innovation and excellence is reflected in its product line, which includes a wide range of components designed to meet the demanding needs of heavy-duty truck applications. Cummins’ commitment to quality and performance ensures that its components, such as the Twelve Point Cap Screw (Part #3065485), deliver reliable and durable solutions for commercial truck operators 8.

Twelve Point Cap Screw 3065485 in Cummins Engines

The Twelve Point Cap Screw 3065485, manufactured by Cummins, is a critical component in several of their engine models. This screw is designed to provide robust fastening capabilities, ensuring secure connections in various engine assemblies.

G8.3 and G855 Engines

In the G8.3 and G855 engines, the 3065485 screw is utilized in several key areas. These engines, known for their reliability and performance, often require precise and strong fastening to maintain structural integrity and operational efficiency. The screw’s twelve-point design allows for better grip and torque application, which is essential in high-stress environments 9.

G855 CM558 and GTA855 CM558 (CM2358) G101 Engines

The G855 CM558 and GTA855 CM558 (CM2358) G101 engines also benefit from the use of the 3065485 screw. These engines, which are part of the advanced CM series, incorporate this screw in critical assemblies where durability and strength are paramount. The screw’s ability to withstand high loads and vibrations makes it an ideal choice for these applications 10.

N14 G Engine

The N14 G engine, another robust Cummins model, utilizes the 3065485 screw in various components. This engine is known for its power and efficiency, and the screw’s design ensures that connections remain tight and secure under demanding conditions 11.

QSK50 CM2150 MCRS Engine

In the QSK50 CM2150 MCRS engine, the 3065485 screw is employed in several strategic locations. This engine, designed for heavy-duty applications, relies on the screw’s strength and precision to maintain the integrity of its assemblies. The twelve-point design facilitates easier and more efficient tightening, which is crucial in complex engine setups 12.

Each of these engines, whether part of the G, GTA, N14, or QSK series, leverages the 3065485 screw to ensure reliable and secure fastening. The screw’s design and material properties make it a versatile and essential component across various Cummins engine models.

Role of Part 3065485 Twelve Point Cap Screw in Engine Systems

The part 3065485 Twelve Point Cap Screw is integral to the assembly and functionality of various engine components. In the motor system, it secures the motor casing to the engine block, ensuring stability and alignment during operation.

In the starting system, this cap screw is used to fasten the starter motor to the engine, providing the necessary torque to initiate engine rotation.

For the pulley system, it plays a role in attaching the pulley to the crankshaft, facilitating the transfer of rotational force to other engine components such as the alternator and water pump.

In the crankshaft assembly, the Twelve Point Cap Screw is employed to secure the crankshaft to the engine block, maintaining the precise alignment required for smooth engine operation.

Within the pump system, it is utilized to attach the fuel pump to the engine, ensuring a secure fit that withstands the pressures and vibrations of fuel delivery.

Lastly, in the vibration damper system, this cap screw is essential for attaching the damper to the crankshaft, helping to absorb and reduce engine vibrations for a smoother running engine 13.

Conclusion

The Twelve Point Cap Screw (Part #3065485) is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its unique design, high-strength material, and corrosion-resistant properties make it an ideal fastening solution for heavy-duty applications. Proper installation and maintenance practices are essential to ensure the longevity and reliability of this part, contributing to the overall performance and safety of the vehicle.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Gas Turbine Engineering Handbook, Second Edition, Meherwan P. Boyce, Gulf Professional Publishing, 2002

↩ -

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ -

Engine: VTA903 CM2250 V105, Bulletin Number: 4332839, Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Gas Turbine Engineering Handbook, Second Edition, Meherwan P. Boyce, Gulf Professional Publishing, 2002

↩ -

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ -

Engine: VTA903 CM2250 V105, Bulletin Number: 4332839, Owners Manual

↩ -

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Gas Turbine Engineering Handbook, Second Edition, Meherwan P. Boyce, Gulf Professional Publishing, 2002

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.