This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3062989 Flat Head Cap Screw is a specialized fastener designed for use in commercial trucks. It is engineered to meet the demanding requirements of heavy-duty environments, ensuring durability and performance in critical truck systems 1.

Basic Concepts of Flat Head Cap Screws

Flat head cap screws are characterized by a flat, countersunk head that sits flush with or below the surface of the material being fastened. They are used in applications requiring a smooth surface or where the screw head needs to be concealed. Mechanically, they convert torque into tensile force, clamping joined materials together securely 2.

Purpose of the Cummins 3062989 Flat Head Cap Screw

This Cummins part is utilized in applications where a low-profile, countersunk fastener is needed to ensure a smooth surface or to reduce the risk of damage from protruding screw heads. It is integral in securing components that require a strong, vibration-resistant connection, contributing to the overall reliability and safety of the truck 3.

Key Features

The 3062989 Flat Head Cap Screw is constructed from high-strength materials, ensuring it can withstand heavy-duty use. It features a specific thread type designed for optimal engagement with mating components, providing a secure fit. Its flat head design allows for flush mounting, reducing the risk of damage and improving aesthetics. Additionally, it may include unique attributes such as corrosion-resistant coatings or specialized threading to enhance its functionality in demanding environments.

Benefits

Using this part offers several benefits. It provides improved fastening security, ensuring that components remain firmly in place under various operating conditions. The design of the screw helps resist vibration loosening, a common issue in heavy-duty applications. Furthermore, its compatibility with various truck components makes it a versatile choice for maintenance and repair tasks.

Installation Guidelines

Proper installation of the 3062989 Flat Head Cap Screw is crucial for ensuring its effectiveness and longevity. Begin by selecting the appropriate drill bit to create a countersunk hole that matches the screw’s head diameter. Use a torque wrench to apply the recommended torque specifications, ensuring the screw is tightened to the manufacturer’s guidelines without over-tightening, which could damage the screw or the material. Recommended tools include a torque wrench, a countersunk drill bit, and a suitable screwdriver or socket.

Troubleshooting and Maintenance

Common issues with flat head cap screws include loosening due to vibration and corrosion. To troubleshoot, inspect the screw and surrounding area for signs of wear or damage. Ensure that the screw is properly torqued and that the mating surfaces are clean and free of debris. Regular maintenance practices, such as checking for tightness and applying corrosion-resistant coatings, can help ensure the longevity and reliable performance of the screw.

Safety Considerations

When working with flat head cap screws, it is important to observe several safety practices. Handle the screws carefully to avoid injury from sharp edges. Store them in a dry, organized environment to prevent corrosion and damage. Use the screws within the specified parameters, following torque specifications and manufacturer guidelines to ensure safe and effective use.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation, providing reliable and efficient solutions for a wide range of industries, including automotive and heavy-duty truck applications. The company’s dedication to excellence is evident in its comprehensive product range and ongoing investment in research and development.

Flat Head Cap Screw 3062989 in Cummins Engines

The Cummins Flat Head Cap Screw part number 3062989 is a critical component in various Cummins engine models, including the N14 CELECT and N14 MECHANICAL engines. This screw is integral to the assembly and operation of these engines, ensuring that various parts are securely fastened and aligned.

N14 CELECT Engine

In the N14 CELECT engine, the 3062989 screw is used in several key areas. It plays a vital role in securing the cylinder head to the engine block, ensuring a tight seal and proper alignment. This is crucial for maintaining engine performance and preventing leaks. Additionally, the screw is used in the fuel injection system, where it helps to attach components that are essential for the precise delivery of fuel to the engine.

N14 MECHANICAL Engine

Similarly, in the N14 MECHANICAL engine, the 3062989 screw is employed in securing the cylinder head and other critical components. Its role in the fuel injection system is equally important, as it helps to maintain the integrity of the system, which is vital for the engine’s efficiency and longevity.

Common Usage Across Models

While the specific applications may vary slightly between the N14 CELECT and N14 MECHANICAL engines, the 3062989 screw is a common component in both. Its use in securing the cylinder head and other critical engine parts highlights its importance in ensuring the engine operates smoothly and reliably. The screw’s design and material ensure it can withstand the high stresses and temperatures within the engine, making it a reliable choice for these applications.

Role of Part 3062989 Flat Head Cap Screw in Engine Systems

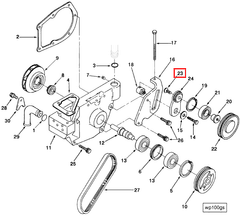

Idler Assembly

In the idler assembly, the 3062989 Flat Head Cap Screw is instrumental in securing the idler pulley to its mounting bracket. This ensures that the pulley remains firmly in place, allowing for smooth and consistent belt tension. Proper tension is essential for the efficient transfer of power from the crankshaft to other engine components, such as the alternator and air conditioning compressor.

Pulley Assembly Support

Within the pulley assembly support, the 3062989 Flat Head Cap Screw plays a significant role in maintaining the structural integrity of the assembly. It secures various pulleys and brackets, ensuring that they remain aligned and stable during engine operation. This alignment is vital for the proper functioning of the serpentine belt, which drives multiple engine accessories.

Water Pump

In the water pump system, the 3062989 Flat Head Cap Screw is used to attach the water pump to the engine block. This secure attachment is necessary for the water pump to operate efficiently, ensuring that coolant is circulated effectively throughout the engine. Proper coolant circulation is essential for maintaining optimal engine temperature and preventing overheating.

Conclusion

The Cummins 3062989 Flat Head Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design, material, and application ensure secure fastening, resistance to vibration loosening, and compatibility with various engine components. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the performance and longevity of this part.

-

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.