This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

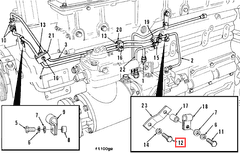

The Injector Stop Screw 3053771, manufactured by Cummins, is a component integral to the management of diesel engines. Cummins, a well-established name in the commercial vehicle industry, produces a wide range of diesel engines and related components designed for durability and efficiency. This Cummins part plays a significant role in the precise control of fuel delivery and engine shutdown procedures, contributing to the overall performance and reliability of diesel engines.

Function and Operation

The Injector Stop Screw 3053771 operates within the fuel injection system of diesel engines. Its primary function is to regulate the fuel delivery to the injectors, ensuring that the engine receives the correct amount of fuel for optimal performance. When the engine is shut down, the screw helps in stopping the fuel supply to the injectors, facilitating a smooth and controlled shutdown process. This component works in conjunction with other parts of the fuel system to maintain precise fuel control, which is vital for engine efficiency and emission control 1.

Key Features

The Injector Stop Screw 3053771 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the harsh conditions within a diesel engine. The screw features precise threading, which ensures a secure fit and reliable operation. Additionally, its design includes attributes that facilitate easy installation and maintenance, contributing to its overall effectiveness in the fuel injection system.

Role in Truck Operation

In the operation of a commercial truck, the Injector Stop Screw 3053771 contributes to several key aspects. It plays a role in maintaining fuel efficiency by ensuring that the engine receives the correct amount of fuel. This precise fuel control also enhances engine performance, allowing the truck to operate smoothly under various conditions. Furthermore, by regulating fuel delivery, the screw aids in emission control, helping the truck meet environmental standards. Its reliable operation is crucial for the consistent performance of the truck’s diesel engine.

Benefits

The Injector Stop Screw 3053771 offers several advantages. One of the primary benefits is its ability to provide precise fuel control, which is essential for the efficient operation of diesel engines. Its robust construction ensures reliability even in harsh operating conditions, reducing the likelihood of failures. Additionally, the screw is designed for ease of maintenance, allowing for straightforward diagnostic and repair procedures, which contributes to its longevity and cost-effectiveness.

Troubleshooting and Maintenance

Common issues associated with Injector Stop Screws can include wear and tear, improper fitting, or contamination. Regular inspection and maintenance are recommended to ensure optimal performance. Diagnostic procedures may involve checking for proper seating, examining the threading for damage, and ensuring there is no debris or contamination in the fuel system. Maintenance practices should include periodic cleaning and, if necessary, replacement of the screw to prevent issues that could affect engine performance 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability in the commercial vehicle industry. The company’s product range includes engines, filtration systems, emissions solutions, and powertrain-related components, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Injector Stop Screw (Part 3053771) in Cummins Engines

The Injector Stop Screw, identified by the part number 3053771, is a critical component in the operation of certain Cummins engines. This screw plays a pivotal role in the precise control of fuel injection, ensuring that the engine operates efficiently and reliably.

N14 Mechanical Engine

In the N14 Mechanical engine, the Injector Stop Screw is integral to the fuel injection system. It is used to adjust the timing of the fuel injectors, ensuring that they open and close at the correct moments during the engine’s operation. This adjustment is crucial for maintaining optimal engine performance and fuel efficiency.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Injector Stop Screw functions in the same capacity. It is employed to fine-tune the fuel injection timing, which is essential for the engine’s overall performance. The screw allows for precise adjustments, ensuring that the fuel injectors operate within the specified parameters, thereby contributing to the engine’s efficiency and longevity.

Compatibility and Importance

The Injector Stop Screw is designed to be compatible with both the N14 Mechanical and NH/NT 855 engines, making it a versatile component in Cummins’ engine lineup. Its importance cannot be overstated, as it directly impacts the engine’s performance and efficiency. Proper adjustment and maintenance of this screw are essential for ensuring that the engine runs smoothly and efficiently.

Role of Part 3053771 Injector Stop Screw in Engine Systems

The injector stop screw, identified by part number 3053771, is an essential component in the regulation and optimization of fuel injection systems within various engine setups. This component works in conjunction with the injector to ensure precise control over the fuel delivery process, which is fundamental for the engine’s performance and efficiency.

Fuel Injection Regulation

In fuel injection systems, the injector stop screw plays a significant role in setting the maximum fuel delivery limit. By adjusting the screw, technicians can fine-tune the amount of fuel that the injector is allowed to dispense during each cycle. This adjustment is vital for maintaining the desired air-fuel ratio, which directly impacts the engine’s performance, emissions, and fuel economy.

Integration with Performance Parts

When upgrading to performance parts, the injector stop screw becomes even more relevant. High-performance injectors often require meticulous calibration to ensure they operate within safe and efficient parameters. The injector stop screw allows for this calibration, enabling engineers and mechanics to maximize the potential of performance injectors without risking engine damage or inefficient fuel usage.

Impact on Engine Performance

The precise functioning of the injector stop screw influences several aspects of engine performance. It helps in achieving smoother idle, more responsive throttle, and overall better drivability. Additionally, in high-performance applications, it ensures that the engine can handle increased fuel demands during acceleration and under load, contributing to enhanced power output and reliability.

Maintenance and Adjustment

Regular maintenance and periodic adjustment of the injector stop screw are necessary to adapt to changes in fuel quality, engine wear, and the installation of aftermarket performance parts. Proper adjustment ensures that the engine continues to perform optimally and meets emissions standards.

Conclusion

The Injector Stop Screw 3053771 is a key component in the intricate dance of fuel delivery and engine performance. Its role in regulating fuel injection, integrating with performance parts, and impacting overall engine performance underscores its importance in both standard and high-performance engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.