This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3044498 Socket Set Screw is a specialized fastener designed for use in commercial trucks. Its primary function is to secure various components within the truck’s mechanical assemblies, ensuring they remain firmly in place under operational conditions. This screw is integral to maintaining the structural integrity and efficient operation of truck systems.

Basic Concepts of Socket Set Screws

Socket set screws are a type of fastener used to secure objects or components within a mechanical assembly. They feature a hexagonal socket in the head, allowing for easy installation and removal using a hex key. These screws function by being driven into a threaded hole, where they exert pressure against another surface to hold components in place. Their applications span various industries, including automotive, aerospace, and manufacturing, where precise and secure fastening is required 3.

Purpose of the 3044498 Socket Set Screw in Truck Operation

In the context of commercial trucks, the 3044498 Socket Set Screw plays a specific role in securing components such as pulleys, gears, and other rotating parts. By ensuring these components remain fixed in position, the screw contributes to the overall structural integrity of the truck. This is particularly important in environments where vibrations and dynamic loads are common, as it helps prevent component misalignment and potential failure 1.

Key Features

The Cummins 3044498 Socket Set Screw is characterized by several key features that enhance its functionality and durability. These include a specific material composition designed to withstand the stresses of truck operation, a threading type that provides secure fastening, and a design that allows for easy installation and adjustment. These features collectively ensure the screw can perform reliably in demanding conditions 2.

Benefits of Using Socket Set Screws

Socket set screws offer several advantages in mechanical assemblies. They provide improved fastening strength compared to other types of fasteners, making them ideal for applications where components must remain securely in place. Additionally, their design allows for easy installation and removal, facilitating maintenance and repair processes. Socket set screws also exhibit resistance to vibration and loosening, which is crucial in dynamic environments like those found in commercial trucks 3.

Installation and Usage Guidelines

Proper installation of the 3044498 Socket Set Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate size and type of screw for the application. Use a hex key to drive the screw into the threaded hole until it makes contact with the component to be secured. Apply the specified torque to ensure the screw is tightened to the correct level without over-tightening, which could damage the screw or the component. Regular checks should be performed to ensure the screw remains securely in place 1.

Troubleshooting Common Issues

Common issues with socket set screws include stripping and cross-threading. Stripping can occur if the screw is over-tightened or if it is not the correct size for the application. To address this, ensure the screw is the appropriate size and apply the correct torque during installation. Cross-threading can happen if the screw is not aligned properly with the threaded hole. To prevent this, carefully align the screw with the hole before driving it in. If cross-threading occurs, remove the screw and clean the threads before attempting to reinstall it 2.

Maintenance Tips

Regular maintenance of socket set screws is important to prolong their lifespan and ensure continued reliable performance. Inspect screws periodically for signs of wear, corrosion, or loosening. Replace any screws that show signs of damage or failure. Additionally, ensure that all components secured by the screws are in good condition and properly aligned to prevent undue stress on the fasteners 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles, ensuring reliable performance and efficiency. Cummins’ dedication to excellence is evident in its comprehensive product line and ongoing investment in research and development.

Socket Set Screw (Part 3044498) in Cummins Engines

The Socket Set Screw, identified by part number 3044498, is a crucial component in the assembly and operation of several Cummins engines. This part is designed to secure various engine parts, ensuring they remain tightly fastened and properly aligned during operation.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the Socket Set Screw plays a vital role in maintaining the integrity of the engine’s internal components. These engines, known for their robust performance and reliability, benefit from the precision and durability of the Socket Set Screw.

-

N14 CELECT: This engine variant utilizes the Socket Set Screw to secure components in its electronically controlled system. The precision of this screw is essential for the smooth operation of the engine’s electronic controls and fuel injection system.

-

N14 MECHANICAL: In the mechanical version, the Socket Set Screw is used to fasten parts that are critical for the engine’s mechanical functions. Its role in maintaining the alignment and tightness of these parts is crucial for the engine’s overall performance and longevity.

The Socket Set Screw’s design ensures it can withstand the high stresses and temperatures encountered in engine environments, making it an indispensable part in both the N14 CELECT and N14 MECHANICAL engines.

Role of Part 3044498 Socket Set Screw in Engine Systems

The part 3044498 Socket Set Screw is integral to the secure assembly and operation of various components within engine systems. Its application ensures the stability and precise functioning of critical elements.

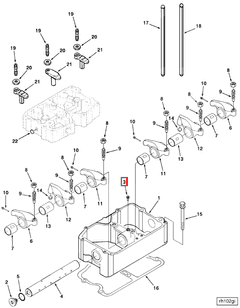

EBM-Lever and Rocker Mechanisms

In the EBM-Lever and Rocker systems, the Socket Set Screw plays a significant role in maintaining the alignment and integrity of the components. It secures the EBM-Lever to the Rocker, ensuring that the mechanical advantage provided by the lever is effectively transmitted to the rocker. This precise attachment is essential for the consistent operation of the engine brake system, which relies on the accurate movement of these components to modulate engine performance.

Engine Brake and Lever Assemblies

When integrated into Engine Brake and Lever Assemblies, the Socket Set Screw ensures that the lever remains firmly attached to the rocker. This secure connection is vital for the reliable actuation of the engine brake, which is used to control engine speed and provide additional braking power. The screw’s ability to withstand vibrational forces within the engine environment is key to maintaining the durability and effectiveness of the brake system.

Rocker Housing and Rocker Lever Housing

In the context of Rocker Housing and Rocker Lever Housing, the Socket Set Screw is used to fasten the rocker lever securely within its housing. This ensures that the rocker lever operates within its designed parameters, contributing to the overall stability and performance of the engine. The screw’s role in preventing any lateral or rotational movement of the rocker lever is essential for the precise timing and efficiency of the engine’s valve operation.

Overall System Integration

Across these applications, the Socket Set Screw’s function extends beyond simple fastening. It contributes to the overall system integration by ensuring that each component operates in harmony with the others. This interdependence is fundamental to the engine’s performance, efficiency, and longevity. The screw’s design and material properties are tailored to meet the demanding conditions within engine systems, providing a reliable solution for component attachment and securement.

Conclusion

The Cummins 3044498 Socket Set Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and features ensure secure fastening of components, contributing to the overall structural integrity and efficiency of the systems it is part of. Proper installation, maintenance, and understanding of its role in various engine systems are essential for maximizing its performance and longevity.

-

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.