This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3043140 Socket Set Screw is a specialized fastener designed for use in commercial truck maintenance and operation. This component is integral to ensuring the secure assembly of various mechanical parts within the truck’s systems. Its role is significant in maintaining the structural integrity and operational efficiency of commercial trucks.

Basic Concepts of Socket Set Screws

A Socket Set Screw is a type of fastener used to secure an object within or against another object, typically to prevent relative motion. It functions by being driven into a pre-drilled hole until it contacts the surface of the mating part, creating a frictional grip. These screws are widely used in mechanical assemblies for their ability to provide a secure hold without the need for a nut 1.

Purpose of the 3043140 Socket Set Screw in Truck Operation

The 3043140 Socket Set Screw plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various mechanical systems where secure fastening is required. This includes applications in engine components, transmission systems, and other critical areas where parts need to be held firmly in place to ensure optimal performance and safety 2.

Key Features

The Cummins 3043140 Socket Set Screw is characterized by several key features that enhance its functionality and durability. It is made from high-quality materials, ensuring resistance to wear and corrosion. The design includes a socket head that allows for easy installation and removal using a suitable tool. Additionally, it may feature unique attributes such as a specific thread pitch or coating to improve performance in demanding environments 3.

Benefits of Using the 3043140 Socket Set Screw

Incorporating the 3043140 Socket Set Screw in truck assemblies offers several advantages. These include improved reliability due to its secure fastening capabilities, ease of installation which reduces downtime during maintenance, and enhanced maintenance efficiency as it allows for quick adjustments or replacements when necessary.

Installation Guidelines

Proper installation of the 3043140 Socket Set Screw involves several steps to ensure optimal performance and longevity. The process requires specific tools, such as a socket wrench, to drive the screw into the pre-drilled hole. Best practices include ensuring the hole is clean and free of debris, using the correct torque specifications to avoid over-tightening, and verifying that the screw is fully seated to achieve the desired grip.

Troubleshooting Common Issues

Common problems associated with Socket Set Screws include wear, corrosion, and improper installation. Signs of these issues may include loosening of the fastener, visible corrosion, or damage to the mating surface. Practical solutions involve regular inspection, proper cleaning and maintenance, and ensuring correct installation techniques are followed to mitigate these problems.

Maintenance Tips

Regular maintenance of the 3043140 Socket Set Screw is vital to ensure continued performance and longevity. This includes routine inspections for signs of wear or corrosion, cleaning the screw and surrounding areas to prevent buildup, and replacing the screw if it shows significant signs of damage or if it becomes loose. Adhering to these maintenance practices helps in maintaining the integrity of the truck’s mechanical systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is committed to advancing technology and sustainability in the commercial truck industry, providing reliable and efficient solutions for its customers.

Socket Set Screw 3043140 in Cummins Engines

The Socket Set Screw 3043140, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of the engines, ensuring that certain parts remain securely fastened.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Socket Set Screw 3043140 plays a vital role in securing various components. Its precise fit and function are essential for maintaining the structural integrity and operational efficiency of the engine.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Socket Set Screw 3043140 is used to fasten and secure parts that are crucial for the engine’s performance. This screw ensures that these parts remain in place under the operational stresses and conditions these engines experience.

The Socket Set Screw 3043140 is designed to meet the rigorous standards required for Cummins engines, ensuring reliability and durability in demanding environments.

Role of Part 3043140 Socket Set Screw in Various Engine Systems

The part 3043140 Socket Set Screw is an integral component in several engine systems, ensuring secure and reliable connections across various assemblies. Its application spans multiple components, contributing to the overall functionality and stability of the engine.

Brake Systems

In brake systems, the Socket Set Screw is utilized to fasten components such as the brake mounting kit and the C-brake kit. It ensures that the brake components remain firmly in place, which is essential for consistent braking performance. The screw is also found in the C-brake (444) kit, where it secures the brake assembly to the vehicle’s frame, enhancing safety and reliability.

Engine and Brake Assemblies

For engine and brake assemblies, the Socket Set Screw plays a significant role in maintaining the integrity of the engine brake mounting kit and the engine group brake. It secures the engine brake to the engine block, ensuring that the braking system operates efficiently without any unwanted movement. This is particularly important in high-stress environments where vibrations and thermal expansion can loosen components.

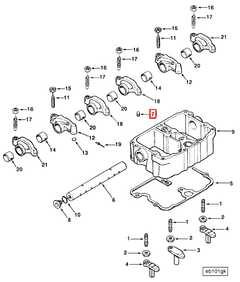

Rocker Housing and Lever Housing

In the rocker housing and rocker lever housing, the Socket Set Screw is employed to secure the housing to the engine block. This is vital for maintaining the precise alignment of the rocker arms, which are responsible for transferring motion from the camshaft to the valves. Proper securing of the rocker housing ensures optimal valve operation, contributing to the engine’s performance and longevity.

Combined Systems

For combined systems such as the brake and engine group, the Socket Set Screw is used to fasten multiple components together, ensuring a cohesive and stable assembly. This is evident in the engine, brake, and rocker lever housing assembly, where the screw helps in maintaining the structural integrity of the entire system.

Specific Applications

- Brake and Mounting: The screw secures the brake components to the mounting points, ensuring stability during operation.

- Brake Engine and Cable: It fastens the brake cable to the engine brake, maintaining tension and alignment.

- Engine Brake Kit: The screw is used to assemble the engine brake kit, ensuring all components are securely in place.

- Rocker Housing Assembly: It secures the rocker housing to the engine, maintaining the alignment of the rocker arms.

The Socket Set Screw’s role in these systems underscores its importance in ensuring that engine and brake components function as intended, contributing to the overall reliability and performance of the vehicle.

Conclusion

The Cummins 3043140 Socket Set Screw is a critical component in the maintenance and operation of commercial trucks. Its role in securing various mechanical parts ensures the structural integrity and operational efficiency of the truck’s systems. Proper installation, regular maintenance, and understanding its applications in different engine systems are essential for maximizing the performance and longevity of this Cummins part.

-

Diesel Emissions and Their Control: Second Edition, Addy Majewski and Hannu Jaskelainen, SAE International, 2023

↩ -

Engineering Mechanics: Statics, Libby Osgood, Gayla Cameron, and Emma Christensen, Creative Commons, 2024

↩ -

Engineering Fundamentals of the Internal Combustion Engine, Willard W. Pulkrabek, Pearson Education, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.