This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3031005 Pan Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This Cummins part is significant in the realm of truck maintenance and operation due to its robust design and reliable performance under demanding conditions.

Basic Concepts of Pan Head Cap Screws

Pan Head Cap Screws are a type of fastener characterized by their wide, rounded heads, which distribute pressure more evenly than other screw types. They are commonly used in fastening applications where a countersunk finish is desired, providing both aesthetic and functional benefits. Mechanically, these screws operate by converting torque into tensile force, securing components together through threaded engagement 1.

Purpose of the 3031005 Pan Head Cap Screw in Truck Operations

The 3031005 Pan Head Cap Screw plays a role in the operation and maintenance of commercial trucks by securing various components that are subject to significant stress and vibration. Its applications range from fastening engine components to securing body panels and other critical parts. The screw’s design ensures a secure fit, contributing to the overall integrity and safety of the vehicle 2.

Key Features of the 3031005 Pan Head Cap Screw

The 3031005 Pan Head Cap Screw is distinguished by several key features that enhance its functionality and durability. These include a specific material composition that offers strength and resistance to wear, a thread type optimized for secure fastening, and a head design that facilitates easy installation and removal. These characteristics collectively contribute to the screw’s ability to perform reliably in demanding truck applications 3.

Benefits of Using the 3031005 Pan Head Cap Screw

Utilizing the 3031005 Pan Head Cap Screw offers several advantages. Its strength ensures that it can withstand the high loads and vibrations typical of truck operations. The screw’s corrosion resistance extends its lifespan, even in harsh environments. Additionally, its design allows for ease of installation, reducing maintenance time and costs. These benefits contribute to improved truck performance and longevity.

Installation and Usage Guidelines

Proper installation of the 3031005 Pan Head Cap Screw involves several steps to ensure a secure and lasting fastening solution. It is recommended to use a torque wrench to achieve the specified torque settings, ensuring that the screw is tightened to the manufacturer’s recommendations without over-tightening, which could lead to damage. Following best practices for installation, such as cleaning the fastening area and using the correct tools, is crucial for optimal performance.

Troubleshooting and Maintenance

Common issues with Pan Head Cap Screws, such as loosening or corrosion, can be addressed through regular maintenance practices. Inspecting screws for signs of wear or damage and replacing them as necessary can prolong their lifespan and ensure continued reliable performance. Additionally, applying a corrosion-resistant coating can protect the screws from environmental factors, further enhancing their durability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s extensive product range and commitment to excellence in manufacturing truck components underscore its position as a trusted partner in the automotive sector.

Pan Head Cap Screw 3031005 in Cummins Engines

The 3031005 Pan Head Cap Screw, manufactured by Cummins, is a critical component in several of their engine models. This screw is designed to provide secure fastening in various engine applications, ensuring the integrity and performance of the engine systems.

G855 and NH/NT 855 Engines

In the G855 and NH/NT 855 engines, the 3031005 is utilized in several key areas. It is often employed to secure components that require a robust and reliable fastening solution. This includes securing certain engine covers and housings, ensuring that these parts remain tightly fastened under operational conditions.

N14 CELECT and N14 MECHANICAL Engines

For the N14 CELECT and N14 MECHANICAL engines, the 3031005 plays a vital role in maintaining the structural integrity of the engine. This screw is commonly used in the assembly of various engine components, including the fastening of internal and external parts that are subject to significant mechanical stress. Its design ensures that these parts remain securely fastened, contributing to the overall reliability and performance of the engine.

QSNT14 CM876 N102 Engine

In the QSNT14 CM876 N102 engine, the 3031005 is integral to the assembly and maintenance of several critical engine components. This screw is used to fasten parts that are essential for the engine’s operation, ensuring that these components remain securely in place under varying operational conditions. Its use in this engine model highlights its versatility and importance in maintaining engine integrity.

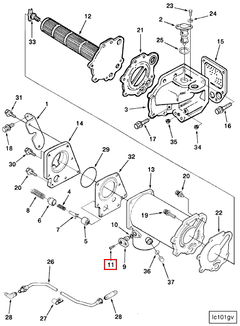

Role of Part 3031005 Pan Head Cap Screw in Engine Systems

The 3031005 Pan Head Cap Screw is integral to the assembly and secure functioning of various engine components. It is commonly used in the fastening of the Engine Oil Cooler and Lubricating Oil Cooler systems, ensuring that these components remain firmly in place under operational conditions.

In the Engine Oil Cooler system, the Pan Head Cap Screw secures the cooler to the engine block or other structural components, maintaining the integrity of the cooling circuit. This is essential for the efficient transfer of heat away from the engine oil, which in turn helps in maintaining optimal engine temperature.

For the Lubricating Oil Cooler and Lubricating Oil Filter / Cooler, the screw plays a similar role. It ensures that these components are tightly fastened, preventing any leaks or misalignments that could disrupt the flow of lubricating oil. This is particularly important in high-performance engines where precise lubrication is required to reduce friction and wear.

Additionally, the Pan Head Cap Screw is used in the assembly of the Filter & Cooler Assy and the Lubricating Oil Filter Head. Here, it secures the filter elements and cooler components, ensuring that they function as intended without any risk of detachment or failure.

In the context of the Full Flow Oil Filter and Lubricating Oil Filter (Top Level Assembly) Head, the screw helps in maintaining the structural integrity of the filter housing. This is vital for the effective filtration of contaminants from the engine oil, which is crucial for prolonging engine life and ensuring smooth operation.

Furthermore, the screw is employed in the mounting of the Pressure Sensing Switch and Sending Unit Mounting. These components rely on secure fastening to accurately monitor and report engine conditions, such as oil pressure and temperature, to the engine control unit.

Overall, the 3031005 Pan Head Cap Screw is a fundamental component in the secure assembly and reliable operation of various engine oil and lubricating oil systems, contributing to the overall efficiency and durability of the engine.

Conclusion

The 3031005 Pan Head Cap Screw is a critical component in the maintenance and operation of commercial trucks, particularly in Cummins engines. Its robust design, reliable performance, and ease of installation make it an essential part for securing various engine components. Regular maintenance and proper installation practices are key to ensuring the longevity and efficiency of this Cummins part in demanding truck applications.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.