This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3022583 Flat Head Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications. This screw is integral to the assembly and maintenance of various truck components, ensuring secure and reliable fastening in critical areas.

Basic Concepts of Flat Head Cap Screws

Flat head cap screws are a type of fastener characterized by a flat, countersunk head that sits flush with or below the surface of the material being fastened. They are commonly used in applications where a smooth surface is required or where the screw head needs to be concealed. Mechanically, these screws function by converting torque applied to the head into tensile force along the screw’s axis, which clamps the joined materials together 1.

Purpose of the 3022583 Flat Head Cap Screw in Truck Operation

This Cummins part plays a role in the assembly and maintenance of commercial trucks by providing secure fastening in various components. It is often used in applications where a low-profile head is necessary to avoid interference with other parts or to maintain aerodynamic efficiency. This screw is employed in critical areas such as engine mounts, chassis components, and body panels, ensuring that these parts remain firmly attached under the rigors of heavy-duty use 2.

Key Features of the 3022583 Flat Head Cap Screw

The 3022583 is designed with several key features that enhance its performance in commercial truck applications. It boasts a robust thread type that provides excellent grip and resistance to loosening. The flat, countersunk head design allows it to sit flush with the surface, reducing the risk of damage to adjacent parts. Additionally, the screw may feature special coatings or treatments to improve corrosion resistance and durability in harsh environments 3.

Benefits of Using the 3022583 Flat Head Cap Screw

Using this part offers several advantages. Its design provides improved fastening strength, ensuring that critical components remain securely attached. The screw’s resistance to loosening helps maintain the integrity of the assembly over time, even under vibration and dynamic loads. Furthermore, its compatibility with high-stress environments makes it an ideal choice for commercial truck applications where reliability is paramount.

Installation Guidelines

Proper installation of the 3022583 is vital to ensure optimal performance. Begin by selecting the appropriate drill bit to create a countersunk hole that matches the screw’s head diameter. Use a torque wrench to apply the specified torque, ensuring that the screw is tightened to the manufacturer’s recommendations without over-tightening, which could damage the screw or the material. Recommended tools include a magnetic screw holder and a socket wrench for precise application.

Troubleshooting Common Issues

Common issues with flat head cap screws include stripping and corrosion. Stripping can occur if the screw is over-tightened or if the material being fastened is too soft. To prevent this, always use the correct torque specifications and ensure the material is suitable for the screw’s thread type. Corrosion can be mitigated by selecting screws with appropriate coatings or treatments for the environment in which they will be used. Regular inspection and maintenance can help identify and address these issues early.

Maintenance Tips

Regular inspection and maintenance of the 3022583 are recommended to ensure longevity and reliable performance. Inspect the screws periodically for signs of loosening, corrosion, or damage. Re-torque screws as necessary to maintain proper clamping force. In environments where corrosion is a concern, consider applying a protective coating or lubricant to the screws and surrounding areas. Keeping screws clean and free of debris will also contribute to their longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to innovation and quality has made it a trusted name in the industry.

Part 3022583 Flat Head Cap Screw Component Usage

This part is integral to the assembly and securement of various engine components, ensuring stability and reliability in operation.

Engine Mounts

In engine mounts, the flat head cap screw is used to fasten the mount brackets to the engine block and the chassis. This securement is essential for maintaining the proper alignment and positioning of the engine within the vehicle. The screw’s design allows for a flush surface, reducing the risk of damage to adjacent components and improving the overall aesthetic of the engine bay.

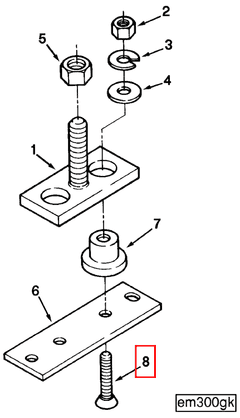

Vibration Isolator Kit

Within the vibration isolator kit, the flat head cap screw plays a significant role in attaching the isolators to the engine and transmission. These isolators are designed to minimize the transmission of engine vibrations to the vehicle’s chassis, enhancing ride comfort and reducing wear on both the engine and chassis components. The screw’s robust construction ensures that the isolators remain firmly in place, even under the dynamic loads experienced during vehicle operation.

The use of the flat head cap screw in these applications underscores its importance in maintaining the integrity and performance of engine systems.

Conclusion

The 3022583 Flat Head Cap Screw is a critical component in the assembly and maintenance of commercial trucks, offering secure fastening, resistance to loosening, and compatibility with high-stress environments. Proper installation, regular maintenance, and understanding of its key features and benefits are essential for ensuring the longevity and reliability of this Cummins part in heavy-duty applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.