This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw, part number 3022153, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of components that contribute to the efficiency and reliability of truck operations. This screw plays a role in securing various components within the truck’s mechanical systems, ensuring both structural integrity and operational stability.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a cylindrical head with a hex socket that allows for installation and removal using a hex key. These screws are commonly used in mechanical assemblies due to their strength and resistance to loosening. They provide a secure fastening solution that can withstand significant stress and vibration, making them suitable for a variety of applications within automotive and heavy-duty truck systems 3.

Role of Socket Head Cap Screw Part #3022153 in Truck Operation

Part #3022153 serves a specific purpose in the context of truck mechanics. It is utilized to secure components that are subject to high stress and vibration, such as engine mounts, transmission components, and chassis parts. By providing a robust fastening solution, this screw helps maintain the structural integrity of these components, which is vital for the safe and efficient operation of the truck 1.

Key Features of Part #3022153

The design of the Socket Head Cap Screw Part #3022153 includes several key features that enhance its functionality. The hex socket head allows for easy installation and removal using a hex key, which provides a more secure and precise fit compared to traditional screwdrivers. Additionally, the screw is crafted from high-strength materials, ensuring it can withstand the demanding conditions encountered in commercial truck applications 2.

Benefits of Using Socket Head Cap Screws

Socket Head Cap Screws offer several advantages in fastening applications. Their strength and resistance to loosening make them ideal for use in environments where vibrations and dynamic loads are common. Additionally, the precision offered by the hex socket head ensures that components are securely fastened, reducing the risk of failure or misalignment. These screws also provide a clean, flush appearance, which can be important in applications where aesthetics are a consideration 3.

Installation and Usage Guidelines

Proper installation techniques are vital to ensure the optimal performance and longevity of Socket Head Cap Screws. It is important to use the correct size hex key to avoid damaging the socket. The screw should be tightened to the manufacturer’s specified torque to ensure a secure fit without over-tightening, which could lead to stripping or damage to the component being fastened. Regular inspection and maintenance can help identify any signs of wear or loosening, allowing for timely replacement or adjustment 1.

Troubleshooting Common Issues

Typical problems associated with Socket Head Cap Screws include stripping and seizing. Stripping can occur if the screw is over-tightened or if the material being fastened is too soft. To prevent this, it is important to use the correct torque settings and to ensure that the screw is compatible with the material being fastened. Seizing can occur if the screw is exposed to corrosive environments. Using screws made from corrosion-resistant materials and applying a suitable lubricant can help mitigate this issue 2.

Maintenance Tips for Socket Head Cap Screws

Regular checks and maintenance practices can help prolong the life of Socket Head Cap Screws and ensure continued reliable operation. Inspecting screws for signs of wear, corrosion, or loosening is important, especially in applications where they are exposed to harsh environments or high stress. Replacing screws that show signs of damage or wear can prevent more serious issues from developing. Additionally, ensuring that all screws are properly torqued during installation can help maintain their integrity over time 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ commitment to innovation and quality has made it a trusted name among truck manufacturers and operators worldwide 4.

Socket Head Cap Screw 3022153 Compatibility with Cummins Engines

This part is a versatile component designed to fit a variety of Cummins engines. It is integral in securing different parts and assemblies within the engine system, ensuring stability and reliability. Below is a detailed description of its compatibility across various Cummins engine models:

CM2670 Series Engines

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

- L9 CM2670 L128B

- X11 CM2670 X126B

- X13 CM2670 X122B

This Cummins part is compatible with the CM2670 series engines, which include the B5.6, B6.7, L9, X11, and X13 models. These engines are known for their robust performance and are used in various applications, from industrial to heavy-duty transport. The screw’s design ensures it can withstand the operational stresses and provide a secure fastening solution.

CM2880 Series Engines

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

The Socket Head Cap Screw 3022153 is also suitable for the CM2880 series engines, which include the ISB5.9, ISG11, ISG12, and ISG12 G CMOH6.0 models. These engines are designed for high-performance applications and benefit from the screw’s ability to maintain tight tolerances and secure connections under demanding conditions.

CM2350 Series Engines

- QSG12/X12 CM2350 G110

- X12 CM2350 X119B

This screw is compatible with the CM2350 series engines, specifically the QSG12/X12 and X12 models. These engines are engineered for durability and efficiency, and the Socket Head Cap Screw 3022153 ensures that critical components remain securely fastened.

Other Cummins Engines

- ISBE4 CM850

- ISF2.8 CM2220 F129

- L10 GAS

- L10 MECHANICAL

- V903

- X12N CMMDG1 X143B

The Socket Head Cap Screw 3022153 also fits various other Cummins engines, including the ISBE4, ISF2.8, L10, V903, and X12N models. These engines cover a wide range of applications, and the screw’s design allows it to be used across different engine types, ensuring a reliable fastening solution.

This comprehensive compatibility ensures that the Socket Head Cap Screw 3022153 can be used across a broad spectrum of Cummins engines, providing a dependable and secure fastening solution for various engine components.

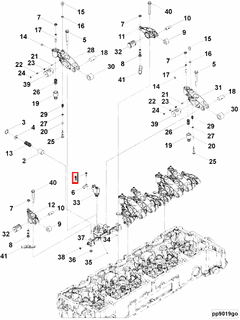

Role of Part 3022153 Socket Head Cap Screw in Engine Systems

The Socket Head Cap Screw 3022153 is instrumental in securing various components within engine systems, ensuring their stability and proper function.

In the Cylinder Head, this screw is used to fasten components that are essential for combustion efficiency and engine performance. It secures parts that contribute to the sealing and structural integrity of the cylinder head, which is vital for maintaining compression and preventing leaks.

Within the Cylinder Top Level Assembly Head, the screw plays a role in attaching components that interface with the cylinder head and the engine block, ensuring a secure and leak-proof connection.

For the Fan Drive system, the Socket Head Cap Screw is employed to fix the fan drive mechanism to the engine, allowing for efficient cooling by ensuring the fan operates correctly in relation to engine speed.

In the Oil Filler Tube Mounting, this screw is critical for securing the oil filler tube to the engine, ensuring that oil can be added without spillage and that the tube remains in the correct position for optimal engine lubrication.

The Rear Gear Housing utilizes the Socket Head Cap Screw to secure the housing to the engine, which is essential for the proper operation of the gear system and the transmission of power from the engine to other components.

For the Rocker Lever and Rocker Lever Support, the screw is used to ensure these components are firmly attached, allowing for precise control over the valve operation, which is fundamental for engine timing and performance.

In the Rocker Top Level Assembly Lever, the screw secures the assembly, ensuring that the rocker arms move smoothly and efficiently, which is necessary for the proper opening and closing of engine valves.

The Water Pump assembly uses the Socket Head Cap Screw to secure the pump to the engine, ensuring efficient coolant circulation, which is essential for maintaining engine temperature within safe operating limits.

Finally, in the Water Top Level Assembly Pump, the screw is used to secure components that are part of the water pump assembly, ensuring that the coolant system functions correctly and that the engine remains cool under operation.

Conclusion

The Socket Head Cap Screw, part number 3022153, is a critical component in the maintenance and operation of Cummins engines. Its robust design, compatibility with a wide range of Cummins engine models, and essential role in securing various engine components make it a vital part of the engine system. Proper installation, maintenance, and understanding of its applications ensure the continued reliability and performance of commercial trucks.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ ↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ ↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ ↩ ↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613140, X13 CM2880 X138B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.