This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Injector Stop Screw 3018772, manufactured by Cummins, is a critical component in the automotive industry, particularly for diesel engines. This part ensures the proper functioning of the fuel injection system in heavy-duty trucks.

Function and Operation

The Injector Stop Screw 3018772 operates within the fuel injection system to control fuel delivery and maintain precise injection timing. It limits the travel of the fuel injector plunger, regulating the amount of fuel injected into the combustion chamber. This control is vital for optimizing engine performance, ensuring efficient combustion, and maintaining consistent power output 1.

Key Features

This Cummins part is designed with features that enhance its performance and durability. It is constructed from high-quality materials that resist wear and corrosion, ensuring longevity in demanding environments. The screw has specific thread specifications for secure installation and adjustment. Additionally, its design includes features that facilitate easy maintenance and replacement, contributing to the overall reliability of the fuel injection system 2.

Benefits

The Injector Stop Screw 3018772 offers several advantages. It contributes to improved fuel efficiency by optimizing the fuel injection process. This optimization leads to enhanced engine performance, as the engine operates more smoothly and efficiently. Furthermore, precise fuel delivery results in reduced emissions, aligning with environmental regulations and promoting sustainable operation. The screw also plays a role in the overall reliability and longevity of the fuel injection system, minimizing the need for frequent repairs or replacements 3.

Installation and Maintenance

Proper installation of the Injector Stop Screw 3018772 is crucial for its effective operation. It should be installed according to the manufacturer’s torque specifications to ensure a secure fit. Alignment requirements must be met to maintain the integrity of the fuel injection system. Regular maintenance is recommended to ensure optimal performance. This includes inspecting the screw for signs of wear or damage and ensuring it is properly lubricated to prevent seizing or malfunction.

Troubleshooting

Common issues associated with Injector Stop Screws include leaks, misfires, or irregular engine performance. These problems can often be traced back to improper installation, wear and tear, or contamination. Diagnostic procedures involve checking the screw for proper seating, inspecting for damage, and ensuring that all connections are secure. If issues are detected, the screw may need to be adjusted, cleaned, or replaced to restore proper function.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry, particularly for its diesel engines and components. The company is committed to innovation and sustainability, offering a wide range of products that meet the needs of various industries, from heavy-duty trucking to power generation.

Cummins Injector Stop Screw (Part 3018772) Compatibility

The Cummins Injector Stop Screw, identified by part number 3018772, is a critical component in the fuel injection system of various engines. This part is designed to ensure precise control over the fuel injection process, enhancing engine performance and reliability. Below is a detailed overview of the engines and engine groups where this part is applicable.

L10 MECHANICAL Engines

The L10 MECHANICAL engine series is known for its robust design and durability, often used in heavy-duty applications. The Injector Stop Screw (3018772) is integral to the proper functioning of the fuel injection system in these engines. It ensures that the injectors are properly calibrated, preventing any potential over-fueling or under-fueling issues that could lead to performance degradation or engine damage.

Group Compatibility

The Injector Stop Screw (3018772) is compatible with a range of engine groups within the L10 MECHANICAL series. This includes:

-

L10 MECHANICAL Group 1: This group comprises engines that are primarily used in industrial and construction machinery. The injector stop screw ensures that the fuel injection timing is precise, which is crucial for maintaining optimal engine performance in these demanding applications.

-

L10 MECHANICAL Group 2: Engines in this group are often found in agricultural and mining equipment. The injector stop screw plays a vital role in ensuring that the fuel injection system operates smoothly under varying load conditions, contributing to the engine’s longevity and efficiency.

-

L10 MECHANICAL Group 3: This group includes engines used in marine and power generation applications. The injector stop screw is essential for maintaining consistent fuel delivery, which is critical for the reliable operation of these engines in harsh marine environments.

By ensuring that the injectors are correctly positioned, the Injector Stop Screw (3018772) helps maintain the integrity of the fuel injection system across these diverse engine groups. This compatibility underscores the importance of using genuine Cummins parts to ensure the best performance and reliability of the L10 MECHANICAL engines.

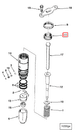

Role of Part 3018772 Injector Stop Screw in Engine Systems

The Injector Stop Screw, identified by part number 3018772, is an integral component in the regulation and management of fuel injection within engine systems. Its primary function is to control the maximum fuel delivery by setting a limit on the injector’s travel. This ensures that the injector does not over-extend, which could lead to excessive fuel delivery and potential engine performance issues.

In the context of an emissions rebuild kit, the Injector Stop Screw plays a significant role in maintaining the precision of fuel injection. Accurate fuel delivery is essential for meeting emissions standards, as it directly impacts the combustion process and the resulting exhaust emissions. By ensuring that the injector operates within specified limits, the screw helps in achieving the desired air-fuel ratio, which is critical for reducing harmful emissions.

When considering the injector itself, the Injector Stop Screw is a key element in its proper functioning. It works in conjunction with the injector mounting to provide a stable and controlled environment for the injector to operate. This interaction is vital for the injector’s performance, as any deviation in the injector’s travel can lead to inconsistent fuel delivery, affecting engine efficiency and power output.

In systems where performance parts are utilized, the Injector Stop Screw becomes even more significant. High-performance engines often require precise fuel delivery to maximize power and efficiency. The screw ensures that the injector’s operation is fine-tuned to meet these demanding requirements, contributing to the overall performance of the engine.

For systems involving PTD (Pump-to-Rail Direct) less link, the Injector Stop Screw helps in maintaining the integrity of the fuel delivery system. By controlling the injector’s travel, it ensures that the fuel pressure and delivery are consistent, which is essential for the reliable operation of PTD systems.

Conclusion

The Injector Stop Screw 3018772 is a fundamental component in various engine systems, contributing to the precision and reliability of fuel injection. Its role in controlling injector travel is essential for maintaining performance, efficiency, and compliance with emissions standards.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.