This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

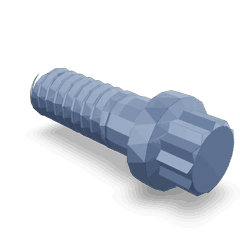

The 3007417 Twelve Point Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality components, including this particular cap screw. The 3007417 Twelve Point Cap Screw is integral to the assembly and maintenance of various truck systems, ensuring secure and reliable connections.

Basic Concepts of Twelve Point Cap Screws

A Twelve Point Cap Screw is a type of fastener characterized by its twelve-sided head, which provides a larger contact area compared to traditional hex cap screws. This design reduces the risk of cam-out during tightening and offers enhanced grip, making it suitable for high-torque applications 2. Twelve Point Cap Screws are commonly used in mechanical assemblies where durability and resistance to loosening are essential.

Function and Role in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks. It is typically used in critical components and systems such as engine mounts, transmission housings, and chassis assemblies. By providing a secure and stable connection, this cap screw helps maintain the integrity and performance of these systems, ensuring the truck operates efficiently and safely 3.

Key Features

The 3007417 Twelve Point Cap Screw features a robust design with a twelve-sided head that enhances its torque capacity and grip. It is made from high-strength materials, ensuring durability and resistance to wear and corrosion. The screw’s unique design includes a larger contact area, which reduces the likelihood of cam-out and provides a more secure fastening solution compared to traditional hex cap screws 1.

Benefits of Using Twelve Point Cap Screws

Using Twelve Point Cap Screws offers several advantages. These screws provide increased torque capacity, allowing for tighter and more secure connections. The reduced risk of cam-out ensures that the screw can be tightened more effectively without slipping. Additionally, the enhanced grip provided by the twelve-sided head helps prevent loosening over time, making these screws ideal for high-stress applications 2.

Installation Considerations

Proper installation of the 3007417 Twelve Point Cap Screw is crucial for ensuring a secure and lasting connection. It is recommended to use the appropriate torque specifications provided by the manufacturer to avoid over-tightening or under-tightening. Using the correct tools, such as a torque wrench, ensures that the screw is installed to the precise torque required. Following best practices, such as cleaning the mating surfaces and inspecting the screw for any damage before installation, will help achieve a reliable connection 3.

Troubleshooting Common Issues

Common issues associated with Twelve Point Cap Screws include loosening, corrosion, and damage. To address these problems, regular inspections should be conducted to identify any signs of wear or corrosion. If a screw is found to be loose, it should be re-tightened to the specified torque. In cases of corrosion, the affected area should be cleaned, and an appropriate corrosion-resistant coating may be applied. Damaged screws should be replaced to maintain the integrity of the assembly 1.

Maintenance Tips

Regular maintenance of Twelve Point Cap Screws is essential to prolong their service life and ensure continued reliable performance. Inspection intervals should be established to check for signs of wear, corrosion, or loosening. Cleaning the screws and their mating surfaces periodically will help prevent buildup and ensure a secure connection. Applying a corrosion-resistant coating can further protect the screws from environmental factors 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of commercial applications 3.

Conclusion

The 3007417 Twelve Point Cap Screw is a vital component in the maintenance and operation of commercial trucks. Its unique design, robust features, and reliable performance make it an essential part for ensuring secure and durable connections in critical truck systems. Proper installation, regular maintenance, and timely troubleshooting are key to maximizing the lifespan and effectiveness of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.