This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3001646 Self Tapping Metal Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this screw to meet the demanding requirements of truck maintenance and repair. This screw is integral to various applications within commercial trucks, ensuring secure and reliable fastening solutions.

Basic Concepts of Self Tapping Metal Screws

Self tapping metal screws are designed to cut their own mating threads as they are driven into a material, eliminating the need for pre-tapping. This feature makes them highly efficient for various fastening applications. In the automotive industry, these screws are commonly used for attaching panels, securing components, and providing robust connections in both metal and plastic materials. Their ability to create threads as they are installed allows for quicker and more convenient fastening processes 1.

Purpose of the 3001646 Self Tapping Metal Screw

The 3001646 Self Tapping Metal Screw plays a specific role in the operation and maintenance of commercial trucks. It is used to secure various components and panels, ensuring that parts remain firmly in place under the rigorous conditions experienced by trucks. This screw is particularly useful in applications where quick and reliable fastening is required, such as in the attachment of body panels, engine components, and other critical parts 2.

Key Features

The 3001646 Self Tapping Metal Screw boasts several key features that enhance its performance and reliability. It is made from high-quality steel, providing excellent strength and durability. The screw features a unique thread design that allows it to cut through materials efficiently while maintaining a strong grip. Additionally, it is coated to resist corrosion, ensuring longevity even in harsh environments. The screw’s design also includes a hexagonal head for easy installation using standard tools 3.

Benefits

Using the 3001646 Self Tapping Metal Screw offers several advantages. Its self tapping design simplifies the installation process, reducing the time and effort required compared to traditional screws. The screw’s durable material and corrosion-resistant coating ensure long-lasting performance, even under the demanding conditions of commercial truck use. Furthermore, the secure fastening provided by this screw helps maintain the integrity of truck components, contributing to overall vehicle safety and reliability 4.

Installation Process

Proper installation of the 3001646 Self Tapping Metal Screw is crucial for optimal performance. Begin by ensuring the screw and the material to be fastened are clean and free of debris. Use a drill with a bit slightly smaller than the screw’s diameter to create a pilot hole, which will guide the screw and reduce the risk of material splitting. Insert the screw into the pilot hole and drive it in using a suitable tool, such as a screwdriver or drill with a hexagonal driver attachment. Ensure the screw is driven in until the head is flush with the material surface, providing a secure and professional finish.

Troubleshooting Common Issues

Common issues with self tapping metal screws include stripped threads, difficulty driving the screw, and corrosion. If threads become stripped, it may be necessary to use a larger screw or repair the threads with a thread repair kit. Difficulty driving the screw can often be resolved by ensuring the pilot hole is the correct size and that the material is free of obstructions. Corrosion can be mitigated by regularly inspecting screws and applying a protective coating if necessary. Proper maintenance and careful installation can prevent many of these issues.

Maintenance Tips

Regular maintenance of the 3001646 Self Tapping Metal Screw can help prevent issues and extend its lifespan. Inspect screws periodically for signs of corrosion or damage. Clean screws and surrounding areas to remove dirt and debris that could contribute to corrosion. If screws show signs of wear or damage, consider replacing them to maintain the integrity of the fastened components. Applying a protective coating can also help prevent corrosion and prolong the life of the screws.

Compatibility and Usage

The 3001646 Self Tapping Metal Screw is designed for use in a variety of commercial truck applications. It is compatible with different truck models and is commonly used for securing body panels, engine components, and other critical parts. Its versatile design makes it suitable for both metal and plastic materials, providing a reliable fastening solution across a range of truck maintenance and repair scenarios.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products, including engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction has established it as a trusted name in the automotive and truck industry.

Self Tapping Metal Screw Part 3001646 Compatibility with Cummins Engines

The Self Tapping Metal Screw part 3001646, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This screw is engineered to provide secure fastening in metal components, ensuring durability and reliability across different engine models.

Compatibility with Specific Engine Models

- 6B5.9: This screw is compatible with the 6B5.9 engine, providing a reliable fastening solution for various components.

- G855: The part 3001646 fits well with the G855 engine, ensuring secure attachment in metal parts.

- K19: The screw is suitable for use in the K19 engine, offering a robust fastening option.

- KTA19GC: This engine model can utilize the part 3001646 for its metal fastening needs.

- N14 CELECT, N14 CELECT PLUS, N14 MECHANICAL: These three variants of the N14 engine all benefit from the use of the part 3001646, providing a consistent fastening solution across different configurations.

- NH/NT 855: The screw is compatible with the NH/NT 855 engine, ensuring secure attachment in metal parts.

- QSNT14 CM876 N102: This engine model can use the part 3001646 for its self-tapping needs, ensuring durability and reliability.

- V28: The screw is suitable for use in the V28 engine, providing a robust fastening option.

- V903: This engine model can utilize the part 3001646 for its metal fastening needs.

Grouping of Compatible Engines

For the engines N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL, the part 3001646 offers a standardized fastening solution, ensuring consistency and reliability across different engine configurations. This grouping highlights the versatility of the screw in catering to various engine models within the same family.

By ensuring compatibility with these engines, the part 3001646 provides a reliable fastening solution, enhancing the overall performance and longevity of the engine components.

Role of Part 3001646 Self Tapping Metal Screw in Engine Systems

The part 3001646 Self Tapping Metal Screw is integral to the assembly and securement of various components within engine systems. Its application spans across multiple parts, ensuring robust connections and efficient operation.

Accessory Cover Mounting

In the accessory cover mounting, the self-tapping metal screw provides a reliable fastening solution. It ensures that the accessory cover remains securely attached to the engine, protecting internal components from debris and external elements.

Accessory Hole Cover and Mounting Cover

For the accessory hole cover and accessory hole mounting cover, the screw plays a vital role in maintaining the integrity of these covers. It prevents any potential leaks or misalignments that could affect engine performance.

After Cooler and Air Aftercooler

In the after cooler and air aftercooler systems, the screw is used to fasten components that are essential for cooling the air before it enters the engine. This ensures optimal air temperature for combustion, enhancing engine efficiency.

Air Intake Manifold and Manifold Air Intake

The air intake manifold and manifold air intake rely on the self-tapping metal screw to secure various connections. This ensures a smooth airflow into the engine, which is critical for maintaining proper air-fuel ratios.

Intercooler and Air Intercooler

For the intercooler and air intercooler, the screw is employed to fasten components that cool the air between stages of compression. This helps in reducing the temperature of the air, thereby increasing its density and improving engine performance.

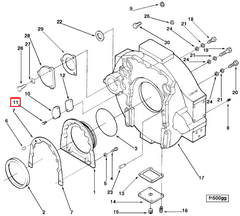

Flywheel and Flywheel Housing

In the flywheel and flywheel housing, the screw ensures that all components are tightly secured. This is essential for maintaining the balance and smooth operation of the flywheel, which is crucial for engine start-up and consistent running.

Guard, Front Engine

The guard, front engine, utilizes the screw to secure the guard in place. This protects the engine from front-end impacts and debris, ensuring longevity and safety.

EBM: Housing and Location

For the EBM (Electric Blower Motor) housing and location, the screw provides a secure attachment point. This is important for the proper functioning and positioning of the EBM within the engine system.

Turbo and Turbo Housing

In turbo and turbo housing applications, the screw ensures that all turbo components are firmly attached. This is essential for maintaining the turbo’s efficiency and preventing any potential leaks that could compromise engine performance.

Rear Cover Plate

Finally, the rear cover plate uses the self-tapping metal screw to secure the plate in place. This ensures that the rear section of the engine is well-protected and all internal components are safely enclosed.

Overall, the part 3001646 Self Tapping Metal Screw is a versatile fastener that plays a significant role in the securement and functionality of various engine components.

Conclusion

The 3001646 Self Tapping Metal Screw is a crucial component in the maintenance and repair of commercial trucks. Its design, featuring high-quality steel, a unique thread design, and corrosion-resistant coating, ensures durability and reliability in various applications. Proper installation and maintenance of this screw contribute to the overall safety and performance of truck components. Its compatibility with a wide range of Cummins engines further underscores its versatility and importance in the automotive industry.

-

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ -

Klyde, Michael and VanGelder, Kirk. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.