The 2897319 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a leading manufacturer of diesel engines and related components, produces this part to ensure reliable fluid transfer in various truck systems. Banjo connector screws play a role in fluid systems by providing a secure connection point for hoses and pipes, facilitating the transfer of fluids such as oil, fuel, or hydraulic fluid.

Basic Concepts and Functionality

A banjo connector screw is a type of fitting used in fluid systems to connect hoses or pipes to components such as pumps, filters, or reservoirs. The basic design of a banjo connector screw includes a threaded body, a sealing washer, and a banjo bolt. The threaded body screws into a corresponding port on the component, while the banjo bolt clamps the hose or pipe in place, creating a secure and leak-free connection. The sealing washer ensures that fluid does not escape between the connector and the component 1.

Purpose and Role in Truck Operation

The 2897319 Banjo Connector Screw plays a role in the operation of a truck by facilitating the transfer of fluids within the system. It ensures that oil, fuel, or hydraulic fluid is delivered efficiently and without leaks, which is important for maintaining system integrity and performance. By providing a reliable connection point, the banjo connector screw helps to prevent fluid loss and ensures that the truck’s systems operate smoothly 2.

Key Features

The 2897319 Banjo Connector Screw features a durable material composition, typically made from high-strength steel or stainless steel, which enhances its resistance to corrosion and wear. It has a specific thread type that matches the ports on Cummins components, ensuring a secure fit. Unique design elements, such as reinforced sealing washers and precision-machined threads, contribute to its functionality and durability 3.

Benefits

Using the 2897319 Banjo Connector Screw provides several benefits. Its design allows for improved sealing, reducing the risk of leaks in the fluid system. The ease of installation, thanks to its threaded design, means that it can be quickly and securely attached to components. Additionally, its resistance to corrosion and high pressures ensures long-lasting performance in demanding truck environments 4.

Installation and Usage

Proper installation of the 2897319 Banjo Connector Screw involves threading it into the corresponding port on the component until it is snug. It is important to follow torque specifications provided by the manufacturer to ensure a secure connection without over-tightening, which could damage the threads or the sealing washer. Using the correct tools and following recommended practices will help achieve a leak-free connection 5.

Troubleshooting and Maintenance

Common issues with banjo connector screws, such as leaks or connection failures, can often be traced to improper installation or wear on the sealing washer. Regular inspection and maintenance, including checking for signs of wear or corrosion, can help prolong the lifespan of the component. Replacing worn washers and ensuring that connections are tight can prevent leaks and ensure optimal performance 6.

Safety Considerations

When working with banjo connector screws, it is important to use the correct tools and follow manufacturer guidelines to prevent accidents. Ensuring that connections are secure and leak-free is important for system reliability and safety. Additionally, wearing appropriate personal protective equipment (PPE) and following safe work practices can help prevent injuries during installation and maintenance 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted provider of high-quality automotive components. The company’s commitment to innovation and excellence is reflected in its wide range of products, including the 2897319 Banjo Connector Screw, which is designed to meet the demanding requirements of commercial truck applications 8.

Cummins Engine Compatibility with Part 2897319

The 2897319 Banjo Connector Screw, manufactured by Cummins, is designed to fit seamlessly within a range of engine models. This component is integral to the proper functioning of the engine’s fuel and hydraulic systems, ensuring secure connections and preventing leaks.

ISX15 CM2250 and ISX15 CM2250 SN

The ISX15 CM2250 and its variant, the ISX15 CM2250 SN, both benefit from the precise fit and reliability of the 2897319 Banjo Connector Screw. This part is crucial for maintaining the integrity of the connections in these engines, which are known for their robust performance and efficiency.

ISX15 CM2350 X101

In the ISX15 CM2350 X101 engine, the 2897319 Banjo Connector Screw is essential for the secure attachment of fuel and hydraulic lines. Its design ensures that the connections remain tight and leak-proof, contributing to the overall reliability of the engine.

QSX15 CM2250 and QSX15 CM2250 ECF

The QSX15 CM2250 and QSX15 CM2250 ECF engines also utilize the 2897319 Banjo Connector Screw. This part is vital for the secure fastening of various lines, ensuring that the engine operates smoothly and efficiently without any risk of leaks.

QSX15 CM2350 X105

Similar to its counterparts, the QSX15 CM2350 X105 engine relies on the 2897319 Banjo Connector Screw for the secure connection of fuel and hydraulic lines. This component’s precision engineering ensures that the connections are both reliable and long-lasting.

X15 CM2350 X116B

The X15 CM2350 X116B engine also incorporates the 2897319 Banjo Connector Screw. This part is essential for maintaining the integrity of the engine’s connections, ensuring that the engine performs at its best with minimal maintenance issues.

Each of these engines, while differing in specific configurations and capabilities, shares a common need for the reliable and precise connection provided by the 2897319 Banjo Connector Screw. This part’s compatibility across these models underscores its importance in maintaining the performance and longevity of Cummins engines.

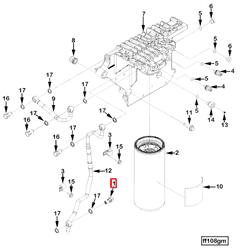

Role of Part 2897319 Banjo Connector Screw in Engine Systems

The 2897319 Banjo Connector Screw plays a significant role in ensuring the integrity and efficiency of fuel delivery systems within various engine setups. This component is integral to the secure connection between the fuel filter and the fuel lines, facilitating a reliable flow of fuel from the tank to the engine.

In the context of the fuel filter, the Banjo Connector Screw ensures a leak-free seal. The fuel filter is responsible for removing impurities and contaminants from the fuel before it reaches the engine. A secure connection is essential to prevent any fuel leaks, which could lead to performance issues or safety hazards. The Banjo Connector Screw achieves this by providing a tight and consistent seal, maintaining the pressure required for optimal fuel delivery.

Additionally, the Banjo Connector Screw is involved in connecting other components within the fuel system, such as fuel rails and injectors. In fuel-injected engines, the fuel rail distributes fuel to each injector, and the Banjo Connector Screw ensures that this distribution is consistent and free from leaks. This reliability is key to maintaining the engine’s performance and efficiency.

Furthermore, in turbocharged engines, where fuel demand is higher, the Banjo Connector Screw’s role becomes even more pronounced. It ensures that the increased fuel flow is managed securely, supporting the engine’s heightened performance requirements without compromising safety.

Overall, the 2897319 Banjo Connector Screw is a fundamental component in maintaining the structural and functional integrity of the fuel system, directly influencing the engine’s overall performance and reliability.

Conclusion

The 2897319 Banjo Connector Screw is a critical component in the fluid systems of commercial trucks, ensuring secure and leak-free connections for hoses and pipes. Its durable construction, precise design, and compatibility with various Cummins engines make it an essential part for maintaining the performance and reliability of truck systems. Proper installation, regular maintenance, and adherence to safety guidelines are important to maximize the benefits of this Cummins part.

-

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.