2897318

Banjo Connector Screw

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

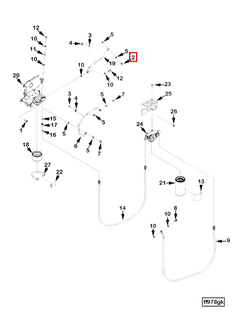

The 2897318 Banjo Connector Screw, manufactured by Cummins, is a specialized component used in commercial trucks. Cummins, a leading manufacturer of diesel engines and related technologies, produces this part to meet the demanding requirements of heavy-duty applications. The banjo connector screw is integral to fluid systems, facilitating the connection of hoses and pipes in hydraulic and fuel systems.

Basic Concepts and Functionality

A banjo connector screw is a type of fitting used to join hoses and pipes in fluid systems. It consists of a bolt with an integrated fitting, often featuring a flat surface or “banjo” shape that allows for the attachment of hoses via clamps. In heavy-duty trucks, these connectors are crucial for maintaining the integrity of fluid pathways, ensuring that hydraulic and fuel systems operate efficiently. The principles of fluid dynamics, such as pressure differentials and flow rates, are relevant to the function of banjo connector screws, as they must withstand high pressures and provide a secure seal to prevent leaks 1.

Purpose of the 2897318 Banjo Connector Screw

The 2897318 Banjo Connector Screw plays a role in the operation of a truck by connecting hoses and pipes in hydraulic and fuel systems. It ensures a reliable seal, which is vital for the efficient transfer of fluids under pressure. This component contributes to the overall efficiency and reliability of the truck’s systems by providing a robust connection point that can endure the rigors of heavy-duty use 2.

Key Features

The design and construction of the 2897318 Banjo Connector Screw include several features that enhance its performance and durability. It is typically made from high-strength materials such as stainless steel, which provides resistance to corrosion and wear. The thread type is designed to ensure a tight fit, and the banjo fitting allows for easy attachment and detachment of hoses. Unique design elements may include reinforced sealing surfaces and precision machining to ensure optimal performance 3.

Benefits

Using the 2897318 Banjo Connector Screw offers several advantages. Its design allows for improved sealing capabilities, reducing the risk of leaks in high-pressure systems. The ease of installation is another benefit, as the banjo fitting simplifies the connection process. Additionally, the material composition provides resistance to corrosion, extending the lifespan of the component. It can also withstand high pressures, making it suitable for demanding applications 4.

Installation and Usage

Proper installation of the 2897318 Banjo Connector Screw is crucial for ensuring a secure and leak-free connection. Guidelines for installation include using the correct torque specifications to avoid over-tightening, which can damage the fitting, or under-tightening, which can lead to leaks. Recommended practices involve using the appropriate tools and ensuring that all surfaces are clean and free of debris before making connections.

Troubleshooting and Maintenance

Common issues with banjo connector screws include leaks and corrosion. Troubleshooting steps may involve inspecting the fitting for signs of wear or damage, ensuring that the torque specifications were followed during installation, and checking for proper alignment of the hose and fitting. Maintenance tips to prolong the lifespan of the connector screw include regular inspection for signs of wear, cleaning the fitting surfaces, and replacing hoses and seals as needed to prevent leaks and ensure optimal performance.

Safety Considerations

When working with banjo connector screws, it is important to follow safety practices to prevent injuries and equipment damage. This includes using appropriate tools to avoid damaging the fitting and wearing personal protective equipment such as gloves and safety glasses. Potential hazards associated with fluid leaks, such as slippery surfaces and flammable fluids, should be mitigated by cleaning up spills immediately and ensuring proper ventilation in work areas.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. Founded in 1919, Cummins has a long history of innovation and quality in the automotive industry. The company is known for producing high-quality components, such as the 2897318 Banjo Connector Screw, which are designed to meet the rigorous demands of commercial and industrial applications.

Cummins Engine Compatibility with Part 2897318

The Banjo Connector Screw, part number 2897318, manufactured by Cummins, is a critical component in the fuel and fluid systems of various Cummins engines. This part is designed to secure hoses and connectors firmly, ensuring leak-free operations and maintaining system integrity.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines benefit from the use of the Banjo Connector Screw in their fuel and fluid lines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The Banjo Connector Screw ensures that the connections in these engines remain tight and secure, preventing any potential leaks that could compromise engine performance.

QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine also utilizes the Banjo Connector Screw in its system. This engine is designed for applications requiring high power and efficiency, such as vocational and on-highway uses. The secure fastening provided by the Banjo Connector Screw is crucial in maintaining the efficiency and reliability of the engine’s fuel and fluid systems.

By integrating the Banjo Connector Screw into their systems, these Cummins engines ensure that their fuel and fluid lines are securely fastened, contributing to the overall performance and longevity of the engine.

Role of Part 2897318 Banjo Connector Screw in Engine Systems

The Part 2897318 Banjo Connector Screw is an essential component in various engine systems, facilitating the secure connection of fluid lines to critical engine components. Its role is particularly significant in the following systems:

Fuel System

In the fuel system, the Banjo Connector Screw ensures a reliable connection between the fuel lines and the fuel filter. This connection is vital for maintaining the integrity of the fuel flow, preventing leaks, and ensuring that the fuel filter receives a consistent supply of fuel. The secure fitting also helps in maintaining the pressure within the fuel lines, which is essential for the efficient operation of the fuel pump.

Fuel Pump

The Banjo Connector Screw is used to connect the fuel lines to the fuel pump. This connection is important for delivering fuel from the tank to the engine under the correct pressure. The screw fitting ensures that the fuel lines are securely attached, reducing the risk of fuel leaks and maintaining the efficiency of the fuel delivery system.

XPI JV System

In the XPI JV System, the Banjo Connector Screw plays a role in connecting various components within the system. This includes securing the connections to the fuel injectors and other critical parts. The secure fitting ensures that the system operates under the correct pressure, which is essential for the precise delivery of fuel to the engine cylinders.

Scania HD Engine

For the Scania HD engine, the Banjo Connector Screw is used in multiple applications, including the connection of fuel lines to the high-pressure fuel system. This ensures that the fuel is delivered to the engine components under the required pressure, contributing to the overall performance and efficiency of the engine.

Conclusion

The 2897318 Banjo Connector Screw is a critical component in ensuring the secure and efficient connection of fluid lines in various engine systems. Its robust design, made from high-strength materials, ensures durability and resistance to corrosion. Proper installation and maintenance are essential to maximize its performance and longevity, contributing to the overall efficiency and reliability of the engine systems in which it is used.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Kasab, John, and Strzelec, Andrea. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.