This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

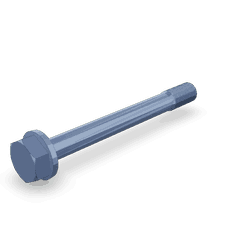

The 2897117 Captive Washer Cap Screw is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw plays a role in the maintenance and operation of commercial trucks, contributing to the overall efficiency and reliability of truck systems.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer. This design ensures that the washer remains in place during installation, reducing the risk of loss and simplifying the assembly process. These screws are commonly used in mechanical assemblies where consistent torque and secure fastening are required 1.

Purpose of the 2897117 Captive Washer Cap Screw in Truck Operation

This Cummins part is designed to provide secure fastening in various applications within commercial trucks. It is used in areas where vibration resistance and consistent clamping force are necessary. This screw helps maintain the integrity of truck components, ensuring they remain securely fastened under operational conditions.

Key Features

The 2897117 is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a hex head for easy installation using common tools. The integrated washer is made from a compatible material, providing a uniform distribution of clamping force. Additionally, the screw features a threaded shaft that ensures a strong grip in the application area.

Benefits

Using this part offers several advantages. Its design enhances reliability by preventing the washer from being misplaced during installation. The integrated washer also ensures consistent torque application, which is vital for maintaining secure fastenings. Furthermore, the ease of installation can lead to time savings during maintenance procedures, potentially reducing overall costs.

Installation Process

To install the 2897117, begin by ensuring the application area is clean and free of debris. Use a torque wrench to apply the specified torque, ensuring the screw is tightened to the manufacturer’s recommendations. It is important to avoid over-tightening, which can damage the screw or the surrounding components. Follow the recommended torque sequence if multiple screws are being installed to ensure even clamping force.

Troubleshooting and Maintenance

Regular inspection of the 2897117 is recommended to identify any signs of wear or corrosion. If the screw shows signs of damage or loosening, it should be replaced to maintain the integrity of the fastening. Proper maintenance includes keeping the application area clean and free of contaminants that could affect the screw’s performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications 2.

Cummins Part 2897117: Captive Washer Cap Screw in Engine Applications

The Cummins part 2897117, a Captive Washer Cap Screw, is integral to the assembly and maintenance of several engine models. This component is designed to secure various parts within the engine, ensuring stability and reliability during operation.

QST30 and CM2350 Engines

In the QST30 and CM2350 engines, the Captive Washer Cap Screw is utilized in several critical areas. These engines, known for their robust performance, require precise fastening to maintain the integrity of their components. The part 2897117 is often employed in securing engine mounts, brackets, and other structural elements that are essential for the engine’s operation. Its design ensures that the washer remains captive, preventing it from being lost during assembly or maintenance, which is crucial for the safety and efficiency of these engines.

T101 Engine

The T101 engine also benefits from the use of the Captive Washer Cap Screw. This engine, designed for high-performance applications, demands reliable fastening solutions to withstand the stresses of its operation. The part 2897117 is used in various applications within the T101, including securing the engine block, cylinder heads, and other critical components. Its captive washer feature ensures that the screw remains securely in place, reducing the risk of loosening over time and enhancing the engine’s overall durability.

Grouping of Engines

The QST30 and CM2350 engines, while distinct in their specific applications, share common design philosophies and engineering principles. The use of the Captive Washer Cap Screw in these engines highlights the importance of precision and reliability in their construction. Similarly, the T101 engine, with its focus on high-performance, also relies on this component to maintain the integrity of its components under demanding conditions.

By integrating the Captive Washer Cap Screw into these engines, Cummins ensures that each part is securely fastened, contributing to the overall performance and longevity of the engine. This thoughtful design approach underscores Cummins’ commitment to quality and reliability in their engine components.

Part 2897117 Captive Washer Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 2897117 Captive Washer Cap Screw is instrumental in ensuring the secure attachment and reliable operation of various components. This screw is specifically designed to integrate a washer within its structure, which enhances its functionality by providing additional support and stability.

Lever Mechanisms

Within lever mechanisms, the 2897117 Captive Washer Cap Screw plays a significant role. It is used to fasten the lever to its mounting point, ensuring that the lever remains firmly in place under operational stress. The integrated washer distributes the load more evenly across the surface, reducing the risk of damage to the lever or its mounting point. This is particularly important in high-stress environments where the lever may be subjected to frequent and intense use.

Rocker Systems

In rocker systems, the 2897117 Captive Washer Cap Screw is employed to secure the rocker arm to its pivot point. The rocker arm, which oscillates to transfer motion, relies on a stable and secure attachment to function correctly. The captive washer within the screw ensures that the connection remains tight, even under the dynamic forces exerted during engine operation. This stability is essential for maintaining the precision and efficiency of the rocker arm’s movement, which directly impacts the engine’s performance.

The use of the 2897117 Captive Washer Cap Screw in these components underscores its importance in maintaining the integrity and reliability of engine systems. Its design facilitates easier assembly and disassembly, reducing the likelihood of losing washers during maintenance, and ensures a consistent and secure connection across various engine applications.

Conclusion

The 2897117 Captive Washer Cap Screw is a vital component in the maintenance and operation of commercial trucks and engine systems. Its design, which includes an integrated washer, ensures secure fastening, consistent torque application, and ease of installation. Regular maintenance and proper installation practices are essential to maximize the benefits of this Cummins part, contributing to the overall efficiency and reliability of truck and engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.