2895392

Socket Head Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Socket Head Cap Screws are essential components in the assembly and maintenance of commercial trucks. They are utilized across various applications due to their robust design and reliable performance. The 2895392 Socket Head Cap Screw by Cummins is a prime example of such a component, designed to meet the demanding requirements of heavy-duty truck operations 3.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a cylindrical head with a hex socket that allows for tool engagement. They are widely used in the automotive industry for their strength and the ease with which they can be installed and removed using a hex key. Mechanically, these screws function by converting torque applied by a tool into clamping force, which holds components together securely 1.

Purpose of the 2895392 Socket Head Cap Screw in Truck Operation

This Cummins part plays a role in various aspects of truck assembly and maintenance. It is employed in engine components, where it helps secure parts that are subject to high stress and vibration. Additionally, it is used in chassis parts, contributing to the structural integrity of the vehicle. Its application extends to other critical areas where secure fastening is required to ensure safe and efficient truck operation 2.

Key Features of the 2895392 Socket Head Cap Screw

The 2895392 is designed with several key features that enhance its functionality. The hex socket head allows for precise tool engagement, facilitating easy installation and removal. The cap of the screw provides a countersunk finish, which enables the screw to sit flush with the surface of the fastened material. The threaded shank ensures a secure and tight fit, which is crucial for maintaining the integrity of the assembly 4.

Benefits of Using the 2895392 Socket Head Cap Screw

There are several advantages to using this part. Its design allows for straightforward installation, reducing the time and effort required during assembly. The screw’s resistance to loosening under vibration is beneficial in the dynamic environment of a commercial truck. Additionally, the countersunk head creates a flush surface, which can improve the aesthetics of the assembly and reduce the risk of snagging on clothing or other materials 3.

Troubleshooting and Maintenance Suggestions

To ensure the longevity and reliable performance of Socket Head Cap Screws, it is important to be aware of common issues such as corrosion or stripping. Regular inspection for signs of wear or damage can help identify problems early. Maintenance practices, such as applying an appropriate lubricant or using corrosion-resistant coatings, can enhance the screw’s performance and lifespan. In cases where a screw has become stripped, it may be necessary to replace it to maintain the integrity of the assembly 1.

Manufacturer Overview - Cummins

Cummins is a well-regarded manufacturer in the automotive industry, known for producing high-quality components. The company has a strong reputation for reliability and innovation, which is reflected in their range of products, including the 2895392 Socket Head Cap Screw. Cummins’ commitment to quality ensures that their components meet the rigorous demands of commercial truck applications 2.

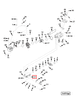

Socket Head Cap Screw 2895392 in Cummins Engines

The Socket Head Cap Screw 2895392, manufactured by Cummins, is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is integral to the assembly and maintenance of several engine models.

B6.7 G CMOH6.0 B125 and ISB6.7 G CM2180 B118

In the B6.7 G CMOH6.0 B125 and ISB6.7 G CM2180 B118 engines, the Socket Head Cap Screw 2895392 is used to secure various engine components, ensuring that parts remain tightly fastened during operation. This screw is essential for maintaining the structural integrity of the engine, particularly in areas where vibration and stress are common.

ISX12 G CM2180 EJ and L8.9G CMOH2.0 L125B

Similarly, in the ISX12 G CM2180 EJ and L8.9G CMOH2.0 L125B engines, the Socket Head Cap Screw 2895392 plays a crucial role. It is used to fasten components that are subjected to high loads and stresses, ensuring that the engine operates smoothly and efficiently. The screw’s design allows for precise torque application, which is vital for the longevity and performance of these engines.

QSB6.7 M CM2250

In the QSB6.7 M CM2250 engine, the Socket Head Cap Screw 2895392 is utilized in a variety of applications. Its robust construction and precise fit are essential for securing components that are critical to the engine’s operation. This screw helps maintain the alignment and stability of parts that are exposed to significant mechanical forces.

Each of these engines benefits from the reliable performance of the Socket Head Cap Screw 2895392, ensuring that all fastened components remain securely in place, contributing to the overall efficiency and durability of the engine 4.

Role of Part 2895392 Socket Head Cap Screw in Engine Systems

The part 2895392 Socket Head Cap Screw is integral to the assembly and maintenance of various engine components. Its primary function is to provide secure fastening, ensuring that components remain firmly in place under the dynamic conditions of engine operation.

In the camshaft guide system, the Socket Head Cap Screw is used to secure the guide in position, allowing for smooth and precise movement of the camshaft. This is essential for maintaining the timing and efficiency of the engine’s valve operation.

When it comes to the camshaft replacer, the Socket Head Cap Screw plays a role in holding the replacement mechanism in place, ensuring that the camshaft can be accurately and securely installed or removed without any misalignment.

In the cleaner air system, these screws are employed to fasten components that filter and direct air into the engine, maintaining the integrity of the air intake system and ensuring optimal air-fuel mixture.

The electronic control module wiring harness relies on Socket Head Cap Screws to secure the harness in place, protecting the wiring from vibrations and ensuring consistent electrical connections throughout the engine system.

Within the fuel control module, these screws are used to attach the module to the engine, guaranteeing that the fuel delivery system operates efficiently and reliably.

For the engine control module and fuel control system, Socket Head Cap Screws are vital in securing these modules, allowing for precise control over engine functions and fuel management.

Lastly, in the engine monitoring system, these screws help in attaching sensors and monitoring devices, ensuring that all components are accurately positioned to provide real-time data on engine performance 3.

Conclusion

The 2895392 Socket Head Cap Screw by Cummins is a critical component in the assembly and maintenance of commercial trucks and various Cummins engines. Its robust design, reliable performance, and key features make it an indispensable part in ensuring the structural integrity and efficient operation of truck and engine systems. Regular maintenance and proper use of this part contribute to the longevity and performance of the vehicles it serves 4.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ ↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ ↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ ↩ ↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.