2887828

Fracture Resistant Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2887828 Fracture Resistant Screw, manufactured by Cummins, is a specialized component designed for use in commercial truck maintenance and operation. Cummins, a well-established name in the industry, produces this screw to meet the demanding requirements of heavy-duty applications. The significance of this screw lies in its ability to withstand high stress and resist fractures, thereby contributing to the reliability and safety of commercial trucks.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to endure significant mechanical stress without breaking. These screws function by distributing stress evenly across their structure, which is achieved through precise design and material selection. The principles of material science and engineering play a vital role in enhancing fracture resistance. Typically, these screws are made from high-strength alloys that offer superior tensile strength and durability. The manufacturing process often includes heat treatment and other techniques to further improve their mechanical properties 1.

Purpose and Role in Truck Operation

The 2887828 Fracture Resistant Screw serves a specific purpose in the context of commercial trucks. It is utilized in areas where components are subjected to high stress and dynamic loads. By providing a secure and durable fastening solution, this screw contributes to the overall functionality and safety of the vehicle. Its role is particularly important in critical assemblies where failure could lead to significant operational issues or safety hazards 2.

Key Features

The 2887828 Fracture Resistant Screw boasts several key features that enhance its performance and durability. Its design includes a threaded shaft that ensures a strong grip, reducing the likelihood of loosening under vibration. The material composition typically consists of high-strength steel alloys, which provide excellent resistance to wear and corrosion. Additionally, the screw may feature a specialized coating that further protects against environmental factors, ensuring long-term reliability.

Benefits

Using fracture resistant screws in commercial trucks offers several advantages. These screws provide increased longevity, reducing the frequency of replacements and associated downtime. They also lower maintenance needs, as their robust design minimizes the risk of failure. Enhanced safety is another significant benefit, as the reliable performance of these screws helps prevent unexpected component failures that could compromise vehicle operation.

Installation Guidelines

Proper installation of the 2887828 Fracture Resistant Screw is crucial for ensuring its effectiveness. Begin by cleaning the installation area to remove any debris or contaminants. Use the appropriate torque wrench to install the screw, ensuring it is tightened to the manufacturer’s specified torque settings. This prevents over-tightening, which could damage the screw or the surrounding components. Follow any additional guidelines provided by Cummins to ensure a secure and proper fit.

Troubleshooting Common Issues

Common problems associated with fracture resistant screws include loosening due to vibration and corrosion. To address these issues, regular inspections should be conducted to check for signs of wear or damage. If corrosion is detected, cleaning the affected area and applying a protective coating can help mitigate further damage. Ensuring that the screw is properly torqued during installation can prevent loosening. Preventive maintenance practices, such as routine checks and re-torquing, are also recommended.

Maintenance Tips

To ensure the longevity and effectiveness of the 2887828 Fracture Resistant Screw, regular maintenance checks are advisable. Inspect the screw periodically for any signs of wear, corrosion, or damage. Re-torque the screw as needed to maintain the proper tension. Additionally, keep the installation area clean and free of contaminants that could accelerate wear or corrosion. Following these maintenance tips will help sustain the screw’s performance over time.

Cummins: A Brief Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history spanning over a century, Cummins has built a reputation for innovation and quality in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ commitment to excellence and customer satisfaction underscores its position as a trusted provider in the industry.

Fracture Resistant Screw (Part 2887828) in Cummins Engines

The Fracture Resistant Screw (Part 2887828) manufactured by Cummins is a critical component in ensuring the structural integrity and operational reliability of several Cummins engine models. This part is specifically designed to withstand high stress and fatigue, which is essential in the demanding environments these engines operate.

Application in QSK95 CM2350 K111 and QSK95 CM2350 K113 Engines

The Fracture Resistant Screw (Part 2887828) is integral to the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are known for their robust performance and are widely used in various industrial and marine applications. The screw’s design ensures that it can endure the rigorous conditions these engines face, including high torque and continuous operation.

In these engines, the Fracture Resistant Screw is used in several key areas where structural integrity is paramount. Its ability to resist fracture under stress helps maintain the alignment and stability of critical engine components, thereby contributing to the overall longevity and efficiency of the engine.

Importance of the Fracture Resistant Screw

The importance of the Fracture Resistant Screw in these engines cannot be overstated. Its design and material properties are specifically tailored to prevent failure under extreme conditions. This is particularly crucial in high-performance engines like the QSK95 CM2350 K111 and QSK95 CM2350 K113, where any failure could lead to significant downtime and costly repairs.

By integrating this screw into the engine’s design, Cummins ensures that the engines can operate reliably even in the most challenging environments. This reliability is a testament to Cummins’ commitment to quality and durability in their engine components.

Role of Part 2887828 Fracture Resistant Screw in Engine Systems

Part 2887828 Fracture Resistant Screw is integral to the secure assembly and reliable operation of several key engine components.

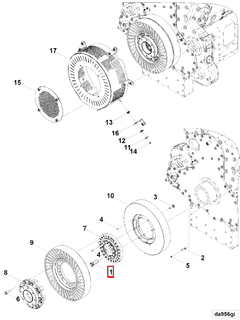

Damper

In the context of engine systems, the damper is designed to absorb and mitigate vibrations generated during operation. The Fracture Resistant Screw ensures that the damper remains firmly attached to its mounting points. This secure attachment is essential for the damper to effectively perform its function, thereby contributing to the overall stability and longevity of the engine.

Vibration

While vibration itself is not a component, it is a byproduct of engine operation that must be managed. The Fracture Resistant Screw plays a role in minimizing unwanted vibrations by ensuring that all connected components, such as the damper and flywheel, are tightly secured. This reduces the likelihood of component loosening over time, which can lead to increased vibration and potential engine damage.

Flywheel

The flywheel is a pivotal component in the engine system, responsible for storing rotational energy and smoothing out the power delivery between engine cycles. The Fracture Resistant Screw is used to secure the flywheel to the crankshaft or other mounting points. This ensures that the flywheel operates within precise tolerances, maintaining engine balance and efficiency. The robust nature of the screw helps in withstanding the high stresses and dynamic loads experienced by the flywheel during engine operation.

Conclusion

The 2887828 Fracture Resistant Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its design and material properties ensure that it can withstand high stress and resist fractures, contributing to the reliability and safety of these vehicles. Proper installation, regular maintenance, and adherence to manufacturer guidelines are essential to maximize the performance and longevity of this screw.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.