This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Screw 2886982, a specialized component designed by Cummins, is crucial for commercial truck maintenance and operation. Engineered to withstand significant mechanical stress, this part ensures the reliability and longevity of truck components, contributing to the vehicle’s overall durability and performance.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws, including the 2886982, are designed to offer enhanced durability and resistance to mechanical stress compared to standard screws. Typically made from materials that provide superior strength and resistance to fracture under load, these screws securely fasten components together while withstanding dynamic forces encountered in mechanical applications. Their importance lies in maintaining structural integrity and preventing failure under stress 1.

Purpose and Role in Truck Operation

The 2886982 Fracture Resistant Screw is utilized in various truck components where durability and resistance to mechanical stress are paramount. Applications include engine components, chassis parts, and other critical areas where standard screws may not provide sufficient strength. By ensuring a secure and lasting connection, this Cummins part contributes to the overall reliability and performance of the truck 2.

Key Features

The 2886982 boasts several key features that set it apart from standard screws. Its material composition is designed to offer enhanced strength and durability. The screw’s design incorporates elements that specifically enhance its fracture resistance, such as a specialized thread pattern and a robust head design. These features work together to provide a screw that can withstand the demanding conditions encountered in commercial truck operation 3.

Benefits

Utilizing the 2886982 offers several advantages. Its increased durability and resistance to mechanical stress mean that it can withstand the rigors of commercial truck operation more effectively than standard screws. This can lead to potential cost savings over time due to reduced maintenance needs and fewer replacements. Additionally, the enhanced performance and reliability provided by this screw contribute to the overall efficiency and safety of the truck.

Installation Considerations

Proper installation of the 2886982 is crucial for optimal performance. Guidelines for installation include adhering to specified torque values to ensure the screw is tightened to the correct level without over-tightening, which could lead to damage. Recommended tools for installation should be used to facilitate a secure and precise fit. Preparatory steps, such as cleaning the installation area and inspecting the screw for any defects, are also important to ensure the screw functions as intended.

Troubleshooting and Maintenance

Common issues that may arise with fracture resistant screws include loosening over time due to vibration or corrosion. Diagnostic steps for identifying problems involve inspecting the screw and surrounding components for signs of wear, corrosion, or damage. Maintenance practices to ensure the longevity and performance of the 2886982 include regular inspections, cleaning, and re-tightening as necessary. Addressing issues promptly can prevent more significant problems and ensure the continued reliability of the truck.

Comparative Analysis

When compared to standard screws and other fracture resistant options available in the market, the 2886982 offers distinct advantages in terms of performance, durability, and application suitability. Its material composition and design elements provide superior strength and resistance to fracture, making it a preferred choice for applications where reliability is critical. Differences in performance and durability are evident in its ability to withstand the demanding conditions of commercial truck operation.

Real-World Applications

The 2886982 is utilized in various commercial truck models and components, demonstrating its versatility and effectiveness in different scenarios. Examples of its application include use in engine components where it secures critical parts under high stress, and in chassis components where it ensures structural integrity. Its effectiveness in these applications showcases the screw’s ability to enhance the durability and performance of commercial trucks.

Manufacturer Overview - Cummins

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to producing high-quality, reliable components for commercial vehicles. With a strong reputation for innovation and excellence, Cummins has established itself as a leader in the field. Their dedication to quality and performance is evident in the design and manufacturing of the 2886982, reflecting their ongoing commitment to providing superior products for the commercial vehicle market.

Fracture Resistant Screw 2886982 in Cummins Engines

The Fracture Resistant Screw 2886982, manufactured by Cummins, is a critical component in several of their engine models. This screw is specifically designed to enhance the durability and reliability of the engines by mitigating the risk of fractures under operational stress.

In the QSK95 series, the screw is integral to the assembly of various engine parts, ensuring that the engine maintains its structural integrity over extended periods of use. The QSK95 CM2350 K111 and QSK95 CM2350 K113 models both utilize this screw in their construction, highlighting its importance in these engine configurations.

The design of the Fracture Resistant Screw 2886982 incorporates advanced materials and engineering techniques to withstand the high-stress environments typical of heavy-duty engines. This ensures that the screw can perform reliably even under the most demanding conditions, contributing to the overall longevity and performance of the engine.

Role of Part 2886982 Fracture Resistant Screw in Engine Systems

Part 2886982, a fracture-resistant screw, is integral to the assembly and functionality of several key engine components. Its application ensures the secure fastening of parts, contributing to the overall stability and performance of the engine.

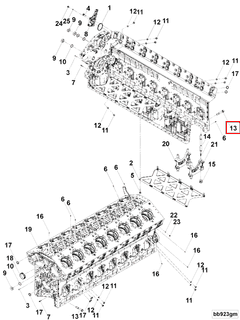

Cylinder Block

In the cylinder block, part 2886982 is utilized to fasten various components securely. This includes attaching the cylinder block kit to the main structure. The screw’s fracture-resistant properties are particularly beneficial in this application, as the cylinder block is subject to significant stress and vibration during engine operation. The secure fastening provided by this screw helps maintain the integrity of the cylinder block, ensuring consistent engine performance.

Engine Crankshaft

The engine crankshaft is another component where part 2886982 plays a significant role. It is used to attach the crankshaft to the cylinder block and other supporting structures. Given the high rotational speeds and forces experienced by the crankshaft, the fracture-resistant nature of the screw is essential. It ensures that the crankshaft remains firmly in place, reducing the risk of misalignment or failure under stress.

Engine Support Arrangement

Part 2886982 is also employed in the engine support arrangement. This includes securing the engine to the vehicle’s frame or other supporting structures. The screw’s ability to withstand significant stress without fracturing is vital in this application. It ensures that the engine remains securely mounted, which is essential for maintaining proper alignment and reducing vibrations that could affect engine performance and longevity.

Conclusion

In summary, part 2886982 fracture-resistant screw is a key component in the secure assembly of various engine parts. Its application in the cylinder block, engine crankshaft, and engine support arrangement highlights its importance in ensuring the structural integrity and reliable performance of engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.