4003912

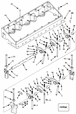

Rocker Lever

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Rocker Lever 4003912 by Cummins is a specialized component designed for use in commercial truck engines. This part is integral to the operation of the engine, facilitating the precise movement of valves in response to camshaft actions. Understanding its purpose and function is key to maintaining engine efficiency and reliability.

Basic Concepts of Rocker Levers

A rocker lever is a mechanical component within an engine’s valve train mechanism. It acts as a lever to transfer motion from the camshaft to the valves. When the camshaft rotates, it pushes against the rocker lever, which then pivots and opens the valve. This mechanism ensures that the valves open and close at the correct times, allowing for the intake and exhaust of air and fuel mixtures necessary for combustion 1.

Purpose and Function of Rocker Lever 4003912

The Rocker Lever 4003912 by Cummins plays a specific role in the engine’s operation by providing a mechanical advantage that allows for efficient valve actuation. It interacts directly with the camshaft and valves, ensuring that the valves open and close with the precision required for optimal engine performance. This component is designed to withstand the high stresses and temperatures within the engine environment, contributing to consistent valve operation 2.

Key Features

The Rocker Lever 4003912 is engineered with specific design and material characteristics to enhance its performance and durability. It is typically made from high-strength materials that resist wear and corrosion. The design may include features such as hardened contact surfaces to reduce friction and wear, and precise machining to ensure accurate valve actuation. These attributes contribute to the component’s reliability and longevity in demanding engine conditions 3.

Benefits

The use of the Rocker Lever 4003912 in commercial truck engines offers several advantages. Its robust design and material properties contribute to improved engine efficiency by ensuring precise valve timing. This precision helps in maintaining optimal combustion, which can lead to better fuel economy and reduced emissions. Additionally, the durability of the rocker lever enhances the overall reliability and longevity of the engine, reducing the need for frequent replacements and maintenance.

Troubleshooting and Maintenance

Common issues associated with rocker levers include wear, noise, and improper valve actuation. Regular inspection and maintenance are recommended to ensure optimal performance. Diagnostic tips may include listening for unusual noises during engine operation, which could indicate wear or misalignment. Maintenance practices should involve checking for proper clearances and ensuring that all contact surfaces are free from debris and corrosion. Timely replacement of worn components can prevent more severe engine issues.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s history of developing reliable and efficient engine components underscores its dedication to advancing technology and meeting the needs of its customers.

Conclusion

The Rocker Lever 4003912 by Cummins is a critical component in ensuring the efficient and reliable operation of commercial truck engines. Its design and function are integral to the precise actuation of engine valves, contributing to optimal engine performance and longevity. Regular maintenance and timely replacement of worn components are essential to prevent engine issues and ensure continued efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.