This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

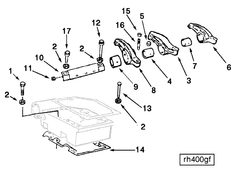

The Cummins 3013300 Rocker Lever is a component designed for use in heavy-duty truck engines. It plays a significant role in the operation of these engines by facilitating the transfer of motion from the camshaft to the valves. This transfer is vital for the engine’s ability to intake air and expel exhaust gases, which are fundamental processes for engine function and performance.

Basic Concepts of Rocker Levers

A rocker lever, in the context of an engine system, is a mechanical component that amplifies and redirects the motion it receives. Typically, it converts the rotational motion of the camshaft into the linear motion needed to open and close the engine’s valves. This conversion is achieved through a pivot point, allowing the lever to rock back and forth, hence its name. The efficiency and precision of this motion transfer are crucial for the engine’s overall performance and efficiency 1.

Purpose of the 3013300 Rocker Lever

The 3013300 Rocker Lever plays a role in the operation of a truck engine by connecting the camshaft’s motion to the valves. It ensures that the valves open and close at the correct times and with the appropriate force. This interaction is critical for maintaining the engine’s combustion process, affecting both the engine’s power output and its fuel efficiency. The rocker lever works in conjunction with pushrods, camshafts, and valve springs, forming a coordinated system that regulates the engine’s air and fuel mixture 2.

Key Features

The 3013300 Rocker Lever is characterized by several key features that enhance its functionality and durability. It is typically made from high-strength materials to withstand the high pressures and temperatures within the engine environment. Its design includes precise machining to ensure smooth operation and minimal friction. Additionally, the lever may feature specific geometries or coatings to improve wear resistance and longevity.

Benefits

The advantages provided by the 3013300 Rocker Lever include enhanced engine performance through precise valve actuation, increased durability due to its robust construction, and improved reliability under demanding operating conditions. These benefits contribute to the overall efficiency and longevity of the engine, making the rocker lever a valuable component in heavy-duty applications.

Installation Process

Installing the 3013300 Rocker Lever requires careful attention to detail to ensure proper function and longevity. The process involves several steps, including preparing the engine compartment, aligning the lever with the camshaft and valve, and securing it in place with the appropriate fasteners. Tools required may include torque wrenches and socket sets to ensure all components are tightened to the manufacturer’s specifications.

Common Issues and Troubleshooting

Common problems associated with the 3013300 Rocker Lever can include wear and tear leading to decreased performance, noise from the valve train, or complete failure in extreme cases. Troubleshooting steps may involve inspecting the lever for signs of wear, checking the alignment and clearances, and ensuring all related components are in good condition. Solutions can range from simple adjustments to replacement of the lever or associated parts 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 3013300 Rocker Lever, regular maintenance practices are recommended. This includes periodic inspections for wear and damage, ensuring proper lubrication, and following the manufacturer’s guidelines for replacement intervals. Keeping the engine clean and well-maintained can also contribute to the rocker lever’s durability and efficiency.

Compatibility and Applications

The 3013300 Rocker Lever is designed for use in specific types of engines and truck models. Its application is primarily within the Cummins engine lineup, where it is used to enhance the performance and reliability of the engine’s valve train system. Compatibility with other engine types or models may vary, and it is important to consult the manufacturer’s specifications for detailed information.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the 3013300 Rocker Lever, which is designed to meet the demanding requirements of heavy-duty applications.

Rocker Lever 3013300 Compatibility with Cummins Engines

The Rocker Lever part number 3013300, manufactured by Cummins, is designed to fit seamlessly into a range of Cummins engines. This component plays a crucial role in the engine’s valve train system, ensuring proper valve operation and overall engine performance.

K19 and K38 Engines

The Rocker Lever 3013300 is compatible with both the K19 and K38 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The lever’s precision engineering ensures it can handle the demands of these engines, providing consistent and reliable valve actuation.

K50 Engine

Similarly, the K50 engine also benefits from the Rocker Lever 3013300. This engine is designed for high-performance and durability, making it suitable for various industrial and commercial applications. The compatibility of the rocker lever with the K50 engine ensures that the valve train operates smoothly, contributing to the engine’s overall efficiency and longevity.

Grouping of Engines

The K19, K38, and K50 engines share common design principles and components, which makes the Rocker Lever 3013300 a versatile part. Its compatibility across these engines highlights its universal design, allowing for easier maintenance and repair across different engine models. This grouping also indicates that the rocker lever is engineered to meet the stringent requirements of Cummins’ high-performance engines.

Role of Part 3013300 Rocker Lever in Engine Systems

The part 3013300 Rocker Lever is an essential component in the operation of various engine systems. It functions by transferring motion from the camshaft to the valves, ensuring precise and timely valve operation. This transfer of motion is fundamental for the intake and exhaust processes within the engine.

In conjunction with the base part, the Rocker Lever amplifies the camshaft’s motion, providing the necessary force to open and close the valves effectively. The base parts serve as the foundation, securing the Rocker Lever in place and ensuring stability during engine operation.

When considering the base parts less rgt, the Rocker Lever still plays a significant role. It maintains the integrity of the valve train system, allowing for smooth and consistent valve actuation. The interaction between the Rocker Lever and these base components is vital for the overall performance and efficiency of the engine.

The part and base work in unison to facilitate the mechanical advantage needed for valve operation. This synergy ensures that the valves open and close at the correct intervals, optimizing the engine’s combustion process.

In summary, the part 3013300 Rocker Lever is integral to the functionality of the engine’s valve train system. Its collaboration with various base components ensures efficient and reliable valve operation, contributing to the engine’s overall performance.

Conclusion

The 3013300 Rocker Lever is a critical component in the operation of heavy-duty truck engines, particularly within the Cummins engine lineup. Its role in transferring motion from the camshaft to the valves ensures precise and timely valve operation, which is fundamental for the engine’s intake and exhaust processes. The lever’s robust construction, precise machining, and compatibility with various Cummins engines highlight its importance in maintaining engine performance and efficiency. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.