Introduction

The Rocker Lever Housing part #3202192 by Cummins is a critical component for heavy-duty truck engines. It houses and supports the rocker levers, which are essential for the valve train mechanism. This part ensures the efficient operation of the engine by maintaining precise valve movement, contributing to the engine’s performance and longevity 2.

Basic Concepts of Rocker Lever Housing

A Rocker Lever Housing is a structural component that encases the rocker levers within the engine. Its primary function is to provide a stable environment for the rocker levers to operate, ensuring they can effectively transfer motion from the camshaft to the valves. This housing interacts closely with the camshaft, pushrods, and valves, playing a pivotal role in the engine’s valve operation system 3.

Purpose of the 3202192 Rocker Lever Housing

The 3202192 Rocker Lever Housing is specifically designed to enhance the operation of a truck engine’s valve train. It facilitates the transfer of motion from the camshaft to the valves via the rocker levers. This part is engineered to withstand the high stresses and temperatures within the engine compartment, ensuring reliable valve actuation and contributing to the engine’s overall efficiency and performance 4.

Key Features

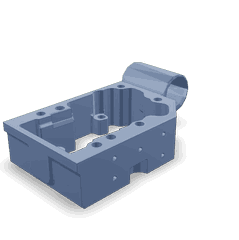

The 3202192 Rocker Lever Housing boasts several key features that enhance its performance and durability. Constructed from high-quality materials, it is designed to resist wear and corrosion. Its design includes precise machining to ensure a perfect fit and optimal function within the engine. Additionally, it features robust mounting points to secure the rocker levers firmly in place, reducing the risk of misalignment or failure under engine stress 1.

Benefits

Incorporating the 3202192 Rocker Lever Housing into a truck engine offers several benefits. It contributes to improved engine efficiency by ensuring smooth and precise valve operation. Its durable construction enhances the engine’s reliability, reducing the likelihood of unexpected failures. Furthermore, the housing’s design helps in maintaining the engine’s performance over time, providing a stable environment for the rocker levers to operate efficiently 2.

Installation Process

Installing the 3202192 Rocker Lever Housing requires careful attention to detail to ensure proper fitting and function. Preparatory steps include cleaning the installation area and inspecting the housing for any damage. Tools required may include torque wrenches and socket sets. The installation process involves positioning the housing over the rocker levers, securing it in place with the appropriate fasteners, and ensuring all connections are tight and secure. It is advisable to consult the engine’s service manual for specific torque specifications and installation guidelines 3.

Common Issues and Troubleshooting

Common issues associated with the 3202192 Rocker Lever Housing may include wear and tear, noise, or malfunctions due to improper installation or engine stress. Troubleshooting steps involve inspecting the housing for signs of damage or wear, ensuring all fasteners are secure, and checking the alignment of the rocker levers. If noise or malfunctions are detected, it may be necessary to disassemble the housing, inspect the rocker levers and other components for damage, and make any necessary repairs or replacements 4.

Maintenance Tips

Regular maintenance of the 3202192 Rocker Lever Housing is crucial for prolonging its lifespan and ensuring optimal engine performance. Maintenance practices include periodic inspection for signs of wear or damage, cleaning the housing to remove any debris or buildup, and ensuring all fasteners remain tight. It is also important to follow the manufacturer’s recommendations for inspection intervals and to consider replacement if significant wear or damage is observed 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product range includes a variety of engine sizes and configurations, designed to meet the diverse needs of the transportation, construction, and industrial sectors. Cummins is known for its commitment to innovation, quality, and customer satisfaction, making it a preferred choice for heavy-duty applications 2.

Compatibility with Cummins Engines

The Rocker Lever Housing part number 3202192 is designed to fit a variety of Cummins engines, ensuring compatibility across multiple models. This part is crucial for maintaining the operational integrity of the engine’s valve train system.

Compatible Engines

- GTA38 G CMEICS G116C

- K19, K38, K50

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

Grouping by Engine Series

The K-series engines, including K19, K38, and K50, are part of a robust line of Cummins engines known for their reliability and performance. The Rocker Lever Housing part 3202192 is engineered to fit seamlessly within these models, providing a secure and durable solution for the valve train.

Similarly, the KTA19GC and KTA38GC CM558 engines also benefit from this part. These engines are designed for heavy-duty applications, and the Rocker Lever Housing plays a critical role in ensuring the smooth operation of the engine’s valves.

The GTA38 G CMEICS G116C engine, while distinct in its design and application, is also compatible with the Rocker Lever Housing part 3202192. This compatibility ensures that the part can be used across a broad range of Cummins engines, providing a standardized solution for maintenance and repair 3.

Role of Part 3202192 Rocker Lever Housing in Engine Systems

The part 3202192 Rocker Lever Housing is an integral component in the efficient operation of various engine systems. It interfaces directly with the rocker lever, which is essential for the mechanical actuation of the engine’s valves. The housing provides a stable and secure environment for the rocker lever, ensuring precise and consistent valve operation.

In conjunction with the lifting arrangement, the Rocker Lever Housing plays a significant role in the valve train system. This arrangement includes components such as the bracket and lifting parts, which work together to facilitate the smooth and reliable movement of the rocker lever. The housing’s design ensures that these parts are correctly aligned and supported, contributing to the overall performance and longevity of the engine.

The interaction between the Rocker Lever Housing and the fuel system is also noteworthy. Efficient valve operation directly influences fuel delivery and combustion efficiency. By ensuring that the rocker lever functions optimally, the housing indirectly supports better fuel economy and engine performance.

Moreover, the housing is part of a comprehensive performance parts strategy. It is designed to withstand the rigors of high-performance applications, providing durability and reliability under demanding conditions. This makes it a key component in both standard and high-performance engine setups 4.

Conclusion

The part 3202192 Rocker Lever Housing is a fundamental element in the engine’s valve train system. Its role in supporting the rocker lever, interacting with the lifting arrangement, and contributing to fuel efficiency underscores its importance in maintaining engine performance and reliability.

-

Sean Bennett and Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition (Delmar Cengage Learning, 2011).

↩ ↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ ↩ ↩ -

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition (Cengage Learning, 2014).

↩ ↩ ↩ -

Moustafa ElGindy and Zeinab ElSayegh, Road and Off-Road Vehicle Dynamics (Springer Nature, 2023).

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.