This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

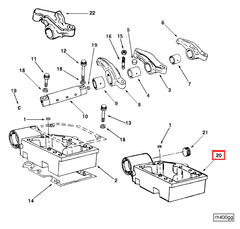

The Rocker Lever Housing, identified by Part #3200480, is a component manufactured by Cummins, a well-established name in the engine manufacturing industry. This housing plays a significant role in the engine system, particularly in the operation of the valve train. Its design and functionality are integral to the efficient and reliable performance of the engine.

Function and Operation

The Rocker Lever Housing operates within the engine by providing a secure mounting point for the rocker arms. These rocker arms are pivotal in transferring motion from the camshaft to the valves, thereby controlling the intake and exhaust processes. The housing ensures that the rocker arms are correctly positioned and supported, which is vital for the precise operation of the valve train. Its interaction with other components, such as the camshaft and valve springs, is crucial for maintaining the engine’s performance and longevity 1.

Key Features

The design of the Rocker Lever Housing is characterized by its robust construction and precise engineering. Typically made from high-strength materials, it is built to withstand the high stresses and temperatures encountered within the engine environment. The housing’s design often includes features such as integrated mounting points and alignment dowels, which enhance its performance and durability. These attributes ensure that the housing can maintain its structural integrity and functional accuracy over the engine’s operational life 2.

Role in Truck Operation

In the context of a commercial truck, the Rocker Lever Housing contributes significantly to the engine’s efficiency and reliability. By ensuring the proper function of the valve train, it plays a role in maintaining the engine’s power output and fuel efficiency. Additionally, its durable construction helps in reducing the likelihood of engine failures, thereby enhancing the truck’s overall reliability and reducing downtime 3.

Benefits

The Rocker Lever Housing offers several advantages, including improved engine performance due to its precise engineering and robust construction. Its durability ensures long-term reliability, reducing the need for frequent replacements. Moreover, the design of the housing can facilitate easier maintenance, allowing for quicker access to the valve train components when necessary.

Troubleshooting and Maintenance

Common issues associated with the Rocker Lever Housing may include wear and tear, misalignment, or damage due to extreme conditions. Regular inspection for signs of wear, such as cracks or deformation, is recommended. Diagnostic tips include checking for proper alignment and ensuring that all mounting points are secure. Maintenance practices should involve cleaning the housing and its surrounding components to prevent the accumulation of debris, which could affect its operation. Additionally, following the manufacturer’s guidelines for inspection intervals and replacement can ensure the longevity and optimal performance of the housing.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and services. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. Their product range includes diesel and natural gas engines, as well as related components and technologies, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted name in the industry.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with specific engine models, ensuring optimal performance and reliability.

K19 and K38 Engines

The Rocker Lever Housing (3200480) is compatible with both the K19 and K38 engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The housing plays a crucial role in these engines by providing a secure mounting point for the rocker levers, which are essential for the valve train operation.

K50 Engine

Similarly, the K50 engine also utilizes the Rocker Lever Housing (3200480). This engine is part of the Cummins lineup that is designed for high-performance and durability. The housing ensures that the rocker levers are properly aligned and supported, which is vital for the smooth operation of the engine’s valve train.

Grouping of Engines

The compatibility of the Rocker Lever Housing (3200480) with the K19, K38, and K50 engines indicates that these engines share a common design philosophy in their valve train mechanisms. This commonality allows for easier maintenance and repair, as the same part can be used across multiple engine models.

By ensuring that the Rocker Lever Housing fits these engines, Cummins maintains a high standard of interchangeability and reliability in their engine components.

Role of 3200480 in Engine Systems

This Cummins part is an integral component in the orchestration of various engine systems, ensuring efficient and reliable performance. It interfaces directly with the camshaft, facilitating the transfer of motion to the valve train. This motion is essential for the precise opening and closing of the engine’s valves, which in turn regulates the intake of air and fuel and the expulsion of exhaust gases.

In conjunction with the intake manifold, the Rocker Lever Housing plays a part in optimizing the airflow into the combustion chambers. Its design and placement contribute to the overall efficiency of the air induction system, impacting the engine’s performance and power output.

The housing is also a key element in the lifting arrangement of the valve train. It supports the rocker arms, which are responsible for amplifying the camshaft’s motion to operate the valves. The integrity and alignment of the Rocker Lever Housing are therefore vital for the consistent and reliable operation of the valve train.

Furthermore, the Rocker Lever Housing is often part of a comprehensive lifting bracket system. This system ensures that the rocker arms are securely held in place and correctly aligned with the camshaft and valves. The housing’s role in this system is to provide a stable and durable platform for the rocker arms, contributing to the longevity and performance of the engine.

In high-performance engine setups, the Rocker Lever Housing may be upgraded or modified as part of performance parts to enhance the engine’s capabilities. Such modifications can include changes to the housing’s material, shape, or internal features to better accommodate higher stresses and more aggressive camshaft profiles.

Additionally, in engines equipped with an aftercooler, the Rocker Lever Housing must be designed to withstand the potentially higher temperatures and pressures that may result from the aftercooling process. This ensures that the housing maintains its structural integrity and functional reliability under these demanding conditions.

Conclusion

In summary, the 3200480 Rocker Lever Housing is a fundamental component that interacts with various engine systems to ensure the smooth and efficient operation of the valve train, contributing to the engine’s overall performance and durability.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.