This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

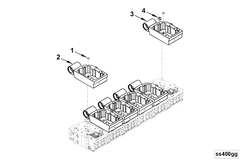

The Rocker Lever Housing 3039097, manufactured by Cummins, is a critical component designed for heavy-duty truck engines. This part plays a significant role in the engine’s valve train system, contributing to the overall efficiency and reliability of the vehicle. Its function in the valve train mechanism ensures smooth engine operation, making it a vital component in the performance of heavy-duty trucks.

Basic Concepts of Rocker Lever Housing

A Rocker Lever Housing is an engine component that encases the rocker arms, which are essential for the operation of the valve train. The housing protects the rocker arms and facilitates their movement, which is crucial for the precise opening and closing of the engine’s valves. This interaction with the valve train is fundamental to the engine’s combustion process, affecting its ability to intake air and expel exhaust 1.

Purpose of Rocker Lever Housing 3039097

The Rocker Lever Housing 3039097 is designed to house and protect the rocker arms within a truck engine. It ensures that the rocker arms operate within a controlled environment, shielding them from debris and excessive wear. This housing is involved in the valve train mechanism, where it allows for the precise movement of the rocker arms, which in turn controls the opening and closing of the engine valves. This precise control is vital for the engine’s performance, affecting both its efficiency and power output 2.

Key Features of Rocker Lever Housing 3039097

The Rocker Lever Housing 3039097 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to wear and corrosion, ensuring longevity in demanding environments. The design of the housing includes precise engineering to accommodate the rocker arms and allow for their smooth operation. Additionally, it may feature unique characteristics such as integrated seals or gaskets to prevent oil leaks and maintain a clean operating environment for the rocker arms 3.

Benefits of Using Rocker Lever Housing 3039097

Utilizing the Rocker Lever Housing 3039097 in a truck engine offers several advantages. It contributes to improved engine efficiency by ensuring that the valve train operates smoothly and precisely. This can lead to better fuel economy and reduced emissions. The housing’s durable construction and protective features enhance the reliability of the engine, reducing the likelihood of unexpected failures. Furthermore, its design can contribute to the longevity of the engine by protecting critical components from wear and damage 4.

Installation and Integration

Installing the Rocker Lever Housing 3039097 requires careful consideration of the engine’s condition and the proper use of tools. It is important to ensure that the engine is clean and free from debris before installation. The housing should be aligned correctly with the rocker arms and secured in place according to the manufacturer’s instructions. Special tools may be required to properly install and adjust the housing, ensuring that it fits snugly and functions as intended within the engine 5.

Troubleshooting Common Issues

Common issues with Rocker Lever Housings can include oil leaks, excessive wear on the rocker arms, or misalignment. These problems can often be traced back to improper installation, lack of maintenance, or the use of incompatible parts. Solutions may involve re-sealing the housing, replacing worn components, or readjusting the housing to ensure proper alignment and operation. Regular inspections and maintenance can help prevent these issues from arising.

Maintenance Tips

To ensure the longevity and optimal performance of the Rocker Lever Housing 3039097, routine maintenance is recommended. This includes regular inspections for signs of wear, corrosion, or oil leaks. Cleaning the housing and its surroundings can prevent the accumulation of debris that may cause damage. Additionally, following the manufacturer’s guidelines for maintenance intervals and procedures can help maintain the housing’s integrity and performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications, ensuring efficiency, durability, and performance.

Role of Part 3039097 Rocker Lever Housing in Engine Systems

The Rocker Lever Housing (part 3039097) is an integral component in the orchestration of various engine systems, ensuring efficient operation and performance.

Interaction with the Camshaft and Gear System

The Rocker Lever Housing interfaces directly with the camshaft and camshaft and gear assembly. This housing provides a stable and secure environment for the rocker arms to pivot, translating the camshaft’s rotational motion into linear motion that operates the valves. This precise movement is essential for the intake and exhaust cycles, directly influencing engine performance and efficiency.

Coordination with Injectors

In engines equipped with direct fuel injection, the Rocker Lever Housing works in conjunction with injectors. It ensures that the fuel delivery system operates smoothly, allowing for optimal air-fuel mixture and combustion. The housing’s design helps maintain the necessary clearances and alignments for the injectors to function correctly.

Support for Oil Control Valve

The oil control valve relies on the Rocker Lever Housing to regulate oil flow to different engine components. The housing provides the structural integrity needed to support the valve and its associated plumbing, ensuring consistent oil pressure and lubrication across the engine.

Integration with Aftercooler Systems

In turbocharged engines, the Rocker Lever Housing is positioned near the aftercooler core and aftercooler plumbing. It plays a role in managing the charged air’s path, ensuring that the air remains cool and dense before entering the combustion chamber. This integration helps in maximizing engine efficiency and power output.

Structural and Protective Functions

The Rocker Lever Housing also incorporates a protective cover that shields sensitive components from debris and excessive heat. Additionally, it often includes a bracket for lifting purposes, facilitating easier maintenance and component replacement.

Enhancing Performance Parts

When upgrading to performance parts, the Rocker Lever Housing becomes even more significant. High-performance camshafts and rocker arms require a housing that can withstand increased stresses and provide precise alignment. The housing’s design can influence the engine’s responsiveness, power output, and overall performance.

Conclusion

In summary, the Rocker Lever Housing (part 3039097) is a multifaceted component that supports and enhances the functionality of various engine systems, from camshaft operations to fuel injection and aftercooling. Its role in maintaining alignment, providing structural support, and ensuring efficient operation of interconnected parts is indispensable for both standard and high-performance engine configurations.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

General Information, Bulletin Number 4021557, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.