4899230

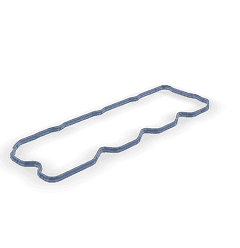

Rocker Lever Housing Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Housing Gasket, identified by Part #4899230, is a component manufactured by Cummins, a well-established name in the automotive industry. This gasket plays a significant role in the operation of heavy-duty truck engines, ensuring the integrity of the valve train system. Its design and function are critical for maintaining engine efficiency and reliability.

Function and Operation

The Rocker Lever Housing Gasket is integral to the engine’s valve train system. It is positioned between the rocker lever housing and the engine block, where it creates a seal that prevents oil leaks. This seal is vital for maintaining the proper lubrication of moving parts within the valve train, ensuring smooth operation and reducing wear. By preventing oil from escaping, the gasket helps maintain the correct oil pressure, which is necessary for the efficient functioning of the engine 1.

Key Features

The Rocker Lever Housing Gasket is designed with specific characteristics to ensure durability and effectiveness. It is constructed from high-quality materials that can withstand the high temperatures and pressures present in heavy-duty truck engines. The gasket features a precise fit, which ensures that it forms a reliable seal without gaps. This design not only enhances the gasket’s performance but also contributes to its longevity 2.

Benefits

The use of the Rocker Lever Housing Gasket offers several advantages. It contributes to enhanced engine performance by ensuring that the valve train system operates efficiently. The gasket’s ability to prevent oil leaks reduces the need for frequent maintenance, saving time and resources. Additionally, by maintaining proper lubrication and preventing wear, the gasket helps prolong the lifespan of engine components 3.

Installation Process

Proper installation of the Rocker Lever Housing Gasket is crucial for its performance and longevity. The process involves cleaning the mating surfaces to ensure a smooth fit, applying a thin layer of gasket sealant if required, and positioning the gasket correctly between the rocker lever housing and the engine block. It is important to follow the manufacturer’s guidelines for torque specifications when securing the housing to avoid over-tightening, which could damage the gasket, or under-tightening, which could lead to leaks.

Common Issues and Troubleshooting

Typical problems associated with the Rocker Lever Housing Gasket include leaks and wear. Leaks may occur due to improper installation, gasket degradation over time, or damage from high temperatures. Wear can result from insufficient lubrication or the use of incompatible materials. Troubleshooting steps include inspecting the gasket for signs of damage, ensuring proper installation, and replacing the gasket if necessary to restore seal integrity.

Maintenance Tips

To maintain the Rocker Lever Housing Gasket, regular inspections are recommended. This involves checking for signs of wear or damage during routine engine maintenance. Best practices for prolonging the gasket’s service life include using high-quality lubricants, following recommended maintenance schedules, and addressing any issues promptly to prevent further damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and emission solutions, demonstrating its commitment to providing comprehensive solutions for its customers.

Compatibility with Cummins Engines

The Rocker Lever Housing Gasket part number 4899230 is designed to fit a range of Cummins engines, ensuring a proper seal and preventing leaks in the rocker lever housing area. This gasket is essential for maintaining engine performance and longevity. Here are the Cummins engines that are compatible with this gasket:

ISB/ISD4.5 Engines

- ISB/ISD4.5 CM2150 B119

- ISD4.5 CM2220 D108

These engines are part of the Cummins ISB/ISD4.5 series, known for their reliability and efficiency in various applications. The 4899230 gasket is specifically engineered to fit the rocker lever housing of these engines, ensuring a tight seal and preventing any oil or coolant leaks.

ISBE Engines

- ISBE CM800

- ISBE4 CM850

The ISBE series engines, including the CM800 and CM850, are designed for heavy-duty applications. The 4899230 gasket is compatible with these engines, providing a crucial seal in the rocker lever housing to maintain optimal engine operation.

QSB4.5 Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

The QSB4.5 engines, such as the CM2250 EC and CM850 (CM2850), are known for their versatility and performance in various industrial and commercial applications. The 4899230 gasket is designed to fit these engines, ensuring that the rocker lever housing remains sealed and free from leaks.

Role of Part 4899230 Rocker Lever Housing Gasket in Engine Systems

The part 4899230 Rocker Lever Housing Gasket is an essential component that ensures the proper functioning and sealing of various engine systems. Here’s how it integrates with the provided components:

Integration with Cylinder Block

The cylinder block serves as the foundational structure of the engine, housing the cylinders, pistons, and other critical components. The Rocker Lever Housing Gasket, when installed correctly, creates a seal between the rocker lever housing and the cylinder block. This seal is vital for maintaining the integrity of the combustion process by preventing oil and coolant leaks, which could otherwise lead to engine damage.

Interaction with Lever and Rocker

The lever and rocker mechanisms are responsible for transferring the motion from the camshaft to the valves. The Rocker Lever Housing Gasket ensures that the housing enclosing these components remains sealed. This prevents any contaminants from entering the housing and ensures that the lever and rocker operate in a clean, lubricated environment, enhancing their longevity and performance.

Role in Long Block Assembly

A long block typically includes the cylinder block, crankshaft, pistons, and other core components but excludes ancillary parts like the fuel system and exhaust manifold. The Rocker Lever Housing Gasket plays a significant role in the long block by ensuring that the upper valve train components are properly sealed. This is particularly important during the reassembly phase of engine maintenance or overhaul, where precise sealing is required to maintain engine efficiency.

Sealing the Rocker Lever Housing

The rocker lever housing is designed to enclose the rocker arms and related components, protecting them from external elements and ensuring smooth operation. The Rocker Lever Housing Gasket forms a critical seal between the housing and adjacent components, such as the cylinder head or valve cover. This seal is essential for maintaining the pressure and vacuum necessary for optimal engine performance.

Component of Upper Engine Gasket Kit and Set

The upper engine gasket kit and set are comprehensive packages that include various gaskets required for the upper portion of the engine, including the valve cover, intake manifold, and rocker lever housing. The Rocker Lever Housing Gasket is a key component in these kits, ensuring that all upper engine components are properly sealed. This comprehensive sealing is essential for preventing leaks and maintaining the engine’s overall performance and reliability.

Conclusion

The 4899230 Rocker Lever Housing Gasket is a critical component in the maintenance and efficiency of Cummins engines. Its proper installation and maintenance are essential for ensuring the longevity and performance of the engine. By understanding its function, benefits, and compatibility with various Cummins engines, users can ensure optimal engine operation and reduce the risk of leaks and other related issues.

-

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.