This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

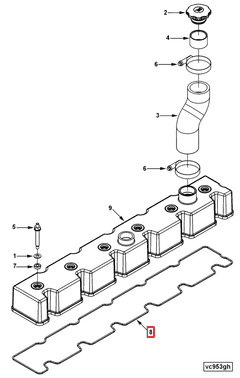

The Rocker Lever Cover Seal, identified by part number 4063961, is a component manufactured by Cummins, a well-established name in the heavy-duty truck engine industry. This seal is integral to the operation of heavy-duty truck engines, ensuring the system’s integrity and efficiency. This overview will delve into the specifics of the Rocker Lever Cover Seal, its placement within the engine, and its role in maintaining optimal engine performance.

Basic Concepts and Functionality

The Rocker Lever Cover Seal is positioned within the engine’s rocker lever cover assembly. Its primary function is to create a barrier that prevents fluid leaks and keeps contaminants from entering the engine. By maintaining a sealed environment, the seal contributes to the overall efficiency and reliability of the engine, ensuring that the internal components operate within the designed parameters 1.

Purpose of the Rocker Lever Cover Seal

The Rocker Lever Cover Seal serves a pivotal role in the operation of a truck engine. It ensures that the rocker lever cover remains sealed, which is vital for maintaining the engine’s lubrication system integrity. This seal helps in preserving the cleanliness of the engine’s internal components by preventing external contaminants from entering. Additionally, it plays a part in maintaining the engine’s efficiency by ensuring that lubrication is consistent and that there are no leaks that could lead to a loss of pressure or performance 2.

Key Features

The 4063961 Rocker Lever Cover Seal is designed with several key features that enhance its performance. It is composed of durable materials that can withstand the high temperatures and pressures within the engine environment. The seal is engineered to fit precisely within the rocker lever cover, ensuring a tight seal. Additionally, it may include unique design elements such as reinforced edges or specialized coatings that further enhance its durability and effectiveness 3.

Benefits

The installation of the Rocker Lever Cover Seal offers several benefits. It contributes to improved engine longevity by ensuring that the engine remains well-lubricated and free from contaminants. This results in reduced maintenance needs, as the seal helps prevent issues that could arise from leaks or contamination. Furthermore, the seal enhances the engine’s overall performance by maintaining system integrity and ensuring that all components operate efficiently.

Installation and Replacement

Proper installation and replacement of the Rocker Lever Cover Seal are vital to ensure its effectiveness. The process involves removing the old seal, cleaning the area, and installing the new seal with the appropriate tools. It is important to follow manufacturer guidelines to ensure a proper fit and seal. Precautions should be taken to avoid damaging the seal or the surrounding components during installation.

Troubleshooting and Maintenance

Common issues with the Rocker Lever Cover Seal may include leaks or signs of wear. Troubleshooting involves inspecting the seal for damage and ensuring that it is properly installed. Regular maintenance, such as checking for signs of wear and ensuring that the seal remains intact, can help prolong its effectiveness. If wear or failure is detected, prompt replacement is recommended to prevent further engine damage.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a strong reputation for quality and innovation. The company has a long history of producing reliable and high-performance engine components. Cummins’ range of products, including the Rocker Lever Cover Seal, plays a significant role in the heavy-duty truck market, providing solutions that enhance engine efficiency and reliability. The company’s commitment to quality is evident in the design and manufacturing of its components, ensuring that they meet the demanding requirements of heavy-duty applications.

Engine Compatibility with Rocker Lever Cover Seal Part 4063961

The Rocker Lever Cover Seal part number 4063961, manufactured by Cummins, is a critical component designed to ensure the integrity of the engine’s rocker lever cover. This seal plays a vital role in preventing oil leaks and maintaining the necessary lubrication within the engine’s rocker arm system.

Application in Specific Engines

6C8.3 Engine

The 6C8.3 engine, known for its robust performance and reliability, integrates the Rocker Lever Cover Seal part 4063961 seamlessly. This seal is specifically engineered to fit the contours and design of the 6C8.3 engine’s rocker lever cover, ensuring a tight and effective seal. Its placement is crucial for maintaining the engine’s operational efficiency and longevity, as it helps to keep contaminants out and lubrication in.

The seal’s design accommodates the unique demands of the 6C8.3 engine, including its high-pressure environment and the constant motion of the rocker arms. By providing a reliable barrier, the seal helps to maintain optimal engine performance and reduces the risk of mechanical failure due to oil leaks or contamination.

Role of Part 4063961 Rocker Lever Cover Seal in Engine Systems

The part 4063961 Rocker Lever Cover Seal is an essential component in maintaining the integrity and efficiency of engine systems. This seal is strategically positioned to interface with the rocker lever cover, ensuring a secure and leak-free environment for the internal components.

Interaction with the Rocker Lever Cover

The Rocker Lever Cover Seal fits snugly around the perimeter of the rocker lever cover. Its primary function is to prevent oil leaks from the valve train area. By creating a tight seal, it ensures that engine oil remains contained within the system, thereby maintaining proper lubrication for the rocker arms, pushrods, and other moving parts.

Sealing the Valve Train

In engine systems, the valve train is a critical assembly that includes components such as the camshaft, lifters, pushrods, and rocker arms. The Rocker Lever Cover Seal plays a significant role in sealing this area. It prevents contaminants from entering the valve train, which could otherwise lead to increased wear and potential failure of these components.

Integration with the Valve Cover

The seal also works in conjunction with the valve cover to provide a comprehensive barrier against oil leakage. The valve cover itself houses the valve train components and is designed to keep them protected from external elements. The Rocker Lever Cover Seal enhances this protection by ensuring that the interface between the rocker lever cover and the valve cover remains sealed.

Maintaining System Pressure

Another important aspect of the Rocker Lever Cover Seal is its role in maintaining system pressure. In engines where positive crankcase ventilation (PCV) systems are employed, the seal helps in keeping the pressure within the crankcase stable. This stability is vital for the efficient operation of the PCV system, which relies on maintaining a slight vacuum to draw crankcase gases back into the intake tract for combustion.

Enhancing Engine Performance

By ensuring that the rocker lever cover and valve train are well-sealed, the Rocker Lever Cover Seal contributes to overall engine performance. It helps in maintaining consistent oil levels, reducing the risk of oil starvation in critical components, and ensuring that the engine operates smoothly and efficiently.

Conclusion

In summary, the part 4063961 Rocker Lever Cover Seal is a vital component that works in harmony with the rocker lever cover, valve cover, and valve train to ensure the engine system functions optimally. Its role in preventing leaks, maintaining system pressure, and enhancing engine performance underscores its importance in the maintenance and efficiency of heavy-duty truck engines.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.