3067459

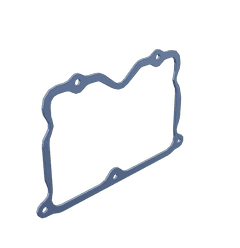

Rocker Lever Cover Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Cover Gasket, identified by Part #3067459, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This gasket is integral to the operation of heavy-duty truck engines, ensuring the efficient and reliable performance of the engine’s rocker lever cover system.

Function and Operation

The Rocker Lever Cover Gasket serves a pivotal role in sealing the rocker lever cover to the engine block. This seal is crucial for preventing oil leaks, which could otherwise lead to engine damage and decreased performance. By maintaining a secure seal, the gasket ensures that the engine’s lubrication system operates effectively, providing the necessary oil flow to critical engine components. This, in turn, helps in reducing friction and wear, contributing to the overall efficiency and longevity of the engine 1.

Key Features

The design and material characteristics of the Rocker Lever Cover Gasket are specifically tailored to meet the demanding requirements of Cummins engines. Crafted from high-quality materials, the gasket is engineered to withstand the high temperatures and pressures present within the engine compartment. Its fit, form, and function are meticulously designed to ensure a precise and durable seal, accommodating the unique contours and specifications of Cummins engines 2.

Benefits

Utilizing a high-quality Rocker Lever Cover Gasket, such as Part #3067459 by Cummins, offers several advantages. These include enhanced engine performance due to effective oil management, reduced maintenance costs as a result of decreased likelihood of oil leaks, and prolonged engine life thanks to the consistent and reliable operation of the lubrication system. The gasket’s durable construction and precise fit contribute to these benefits, making it a valuable component in the maintenance and operation of heavy-duty truck engines.

Installation and Maintenance

Proper installation of the Rocker Lever Cover Gasket is vital for its effectiveness and longevity. Installation procedures should adhere to manufacturer guidelines, including the use of specified torque settings to ensure a secure fit without over-tightening, which could damage the gasket or engine components. Additionally, applying the correct sealing techniques, such as using a light coating of engine oil on the gasket’s surface, can enhance its sealing capabilities. Regular maintenance checks are recommended to ensure the gasket remains in good condition, with any signs of wear or damage addressed promptly to prevent potential engine issues.

Troubleshooting Common Issues

Common problems associated with Rocker Lever Cover Gaskets include oil leaks and gasket failure. These issues can often be identified through visual inspection or by monitoring engine performance and oil levels. Diagnostic methods may involve checking for signs of oil seepage around the rocker lever cover or analyzing engine operation for any irregularities that could indicate a gasket issue. Recommended solutions typically involve replacing the gasket with a new one, ensuring that the replacement part is compatible with the engine model and meets the necessary quality standards.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industries for producing reliable, high-performance engines and components. The company’s product portfolio includes a wide range of engines and technologies designed to meet the diverse needs of its customers, from on-highway and off-highway applications to industrial and marine uses. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a leader in the industry.

Cummins Rocker Lever Cover Gasket 3067459 Compatibility

The Cummins Rocker Lever Cover Gasket part number 3067459 is designed to fit seamlessly with several engine models, ensuring a secure seal between the rocker lever cover and the engine block. This gasket is critical for maintaining the integrity of the engine’s lubrication system and preventing oil leaks.

N14 MECHANICAL Engines

For the N14 MECHANICAL engines, the Rocker Lever Cover Gasket 3067459 is engineered to provide a precise fit, ensuring that the gasket forms a tight seal. This is crucial for maintaining optimal engine performance and preventing oil from leaking out of the rocker lever cover area.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the use of the Rocker Lever Cover Gasket 3067459. This gasket is designed to match the specific contours and dimensions of the rocker lever cover in these engines, ensuring a reliable seal that prevents oil from escaping and maintains engine efficiency.

General Compatibility

The Rocker Lever Cover Gasket 3067459 is crafted with high-quality materials that can withstand the high temperatures and pressures found in diesel engines. Its design ensures that it can adapt to the unique requirements of different engine models, providing a consistent and reliable seal across various applications.

Role of Part 3067459 Rocker Lever Cover Gasket in Engine Systems

The part 3067459 Rocker Lever Cover Gasket is an essential component in maintaining the integrity and efficiency of various engine systems. It is specifically designed to seal the rocker lever housing, preventing oil leaks and ensuring that the internal components remain properly lubricated.

Integration with Engine Components

-

Rocker Cover Mounting and Housing: The gasket fits between the rocker cover and the cylinder head, providing a seal that is vital for the operation of the rocker lever system. This ensures that oil does not escape from the housing, which could lead to insufficient lubrication of the rocker arms and other moving parts.

-

Valve Covers & Breather: When installed, the gasket works in conjunction with the valve covers and breather system to maintain a consistent pressure within the crankcase. This is important for the proper functioning of the crankcase breather, which helps to vent gases and moisture from the engine.

-

Crankcase and Breather Vent Tube: The seal provided by the gasket is also important for the crankcase breather system. It ensures that the breather vent tube can effectively remove unwanted gases without allowing oil to escape, which could contaminate other engine components or the environment.

-

Upper Engine Gasket Set and Head Gasket Set: As part of the upper engine gasket set, the Rocker Lever Cover Gasket complements other gaskets such as the upper head gasket set. Together, they create a comprehensive sealing solution that protects the engine’s internal environment.

-

Engine Brake System: In engines equipped with an engine brake, the gasket plays a role in maintaining the seal around the engine brake housing and gasket set. This is important for the efficient operation of the engine brake system, ensuring that it functions correctly without oil contamination.

-

Onboard Spares and Overland Kit: For vehicles with onboard spares or overland kits, the integrity of the Rocker Lever Cover Gasket is important for maintaining engine performance during long journeys or in remote locations where immediate repairs may not be possible.

-

Tachometer Parts Kit: Although indirectly related, the proper sealing provided by the gasket ensures that engine components, including those monitored by a tachometer, operate within expected parameters, providing accurate readings and diagnostics.

Conclusion

In summary, the part 3067459 Rocker Lever Cover Gasket is a key component in the maintenance of engine systems, ensuring that seals are maintained, pressures are consistent, and lubrication is effective across a range of engine operations and configurations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.