This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

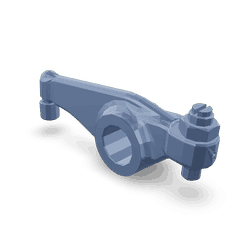

The Cummins 5282811 Rocker Lever is a component designed for use in commercial truck engines. It plays a role in the engine’s operation by facilitating the movement of the valves, which is important for the intake and exhaust processes. Understanding its function and significance can provide valuable insights into the overall performance and reliability of truck engines.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a mechanical component found in internal combustion engines. It operates within the valve train mechanism, transferring motion from the camshaft to the valves. When the camshaft lobe rises, it pushes against the rocker lever, which then pivots and opens the valve. This action allows air and fuel to enter the combustion chamber or exhaust gases to exit, depending on the engine cycle phase 1.

Purpose of the 5282811 Rocker Lever

The Cummins 5282811 Rocker Lever is specifically engineered to enhance the efficiency and reliability of truck engines. It interacts with other components such as pushrods and valves to ensure precise and timely valve operation. The rocker lever amplifies the motion from the camshaft, providing the necessary force to open the valves effectively. This interaction is vital for maintaining optimal engine performance and fuel efficiency 2.

Key Features

The Cummins 5282811 Rocker Lever is constructed from high-quality materials, ensuring durability and performance under demanding conditions. Its design includes features such as a hardened surface to resist wear and a precise pivot point to ensure smooth operation. Additionally, the rocker lever may incorporate roller tips to reduce friction and enhance efficiency. These characteristics contribute to its reliability and longevity in heavy-duty applications 3.

Benefits

The use of the Cummins 5282811 Rocker Lever offers several advantages. It contributes to improved engine efficiency by ensuring precise valve timing and operation. The durable construction and design elements enhance the component’s longevity, reducing the need for frequent replacements. Furthermore, the reliable performance of the rocker lever under heavy-duty conditions supports the overall efficiency and reliability of the truck engine 4.

Installation and Compatibility

Proper installation of the Cummins 5282811 Rocker Lever is crucial for ensuring its effective operation. It is important to follow manufacturer guidelines to achieve the correct fit and function. Compatibility with specific engine models and configurations should be verified to ensure optimal performance and integration within the engine system.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 5282811 Rocker Lever. Regular inspections for wear and proper lubrication are essential. Common issues may include wear on the pivot point or roller tips, which can be addressed through timely maintenance or replacement. Troubleshooting steps should involve checking for proper valve operation and ensuring there are no obstructions or misalignments.

Performance Enhancements

While the Cummins 5282811 Rocker Lever is designed for reliable performance, there may be opportunities for enhancements to further optimize engine performance. This could involve upgrading to high-performance rocker levers or modifying existing components to improve efficiency and power output. Such modifications should be approached with caution and ideally performed by experienced professionals to ensure compatibility and safety.

Cummins Corporation

Cummins Corporation is a renowned manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company is committed to producing high-quality components that enhance the performance and reliability of engines. With a history of innovation and excellence, Cummins continues to be a trusted name in the manufacturing of automotive parts, including the 5282811 Rocker Lever.

Cummins Rocker Lever 5282811 in Engine Applications

The Cummins Rocker Lever part number 5282811 is a component in several engine models, ensuring smooth and efficient operation. This part is integral to the valve train mechanism, facilitating the opening and closing of engine valves.

QSB3.3 CM2250 EC

In the QSB3.3 CM2250 EC engine, the Rocker Lever 5282811 plays a role in the valve train system. It is designed to interface with the camshaft and pushrods, ensuring precise valve timing and operation. This engine is known for its robust performance and reliability, often used in various industrial and commercial applications.

Grouping of Engines

The Rocker Lever 5282811 is compatible with a range of Cummins engines, including but not limited to the QSB3.3 series. This part’s design allows it to fit seamlessly into these engines, providing consistent performance and durability. The compatibility ensures that maintenance and repair processes are streamlined, reducing downtime and enhancing operational efficiency.

Role of Part 5282811 Rocker Lever in Engine Systems

The Part 5282811 Rocker Lever is an integral component within the engine’s valve train system, facilitating the transfer of motion from the camshaft to the valves. This transfer is essential for the precise timing of valve opening and closing, which directly influences engine performance and efficiency.

Interaction with the Camshaft

The Rocker Lever engages with the camshaft through a cam lobe. As the camshaft rotates, driven by the engine’s crankshaft via a timing belt or chain, the cam lobe pushes against the Rocker Lever. This action causes the Rocker Lever to pivot, initiating the valve operation sequence.

Connection to the Valve

On the opposite end of its pivot point, the Rocker Lever is connected to the valve stem via a pushrod in overhead valve (OHV) engines or directly in overhead cam (OHC) engines. When the Rocker Lever pivots, it either pushes down or pulls up on the valve stem, depending on the engine’s design, to open the valve. The spring-loaded valve then returns to its closed position once the Rocker Lever moves back to its original position.

Role in the Valve Train

Within the valve train, the Rocker Lever serves as a force multiplier. It amplifies the motion initiated by the camshaft, ensuring that the valve opens sufficiently to allow the necessary airflow into and out of the combustion chamber. This is vital for maintaining the engine’s air-fuel mixture and combustion efficiency.

Integration with Other Components

The Rocker Lever Assembly, which includes the Rocker Lever, mounting bracket, and any associated hardware, is designed to withstand the high stresses and temperatures within the engine compartment. Its precise fit and function are essential for the durability and performance of the engine. The assembly must be correctly aligned and secured to prevent any misalignment that could lead to valve train noise, reduced efficiency, or engine damage.

Conclusion

In summary, the Part 5282811 Rocker Lever plays a significant role in the engine’s operation by ensuring the valves open and close at the correct times and with the appropriate force. Its interaction with the camshaft, valve, and other components within the valve train is fundamental to the engine’s overall performance and longevity.

-

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.