This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Rocker Lever Adjusting Screw, identified by part number 4006269, is a component manufactured by Cummins, a well-established name in the engine manufacturing industry. This screw plays a significant role in the operation of the engine, particularly within the valve train system. Its design and function are integral to maintaining the efficiency and reliability of Cummins engines 1.

Function and Operation

The Rocker Lever Adjusting Screw operates within the engine’s valve train system, where it is responsible for maintaining proper valve clearance. This clearance is vital for the efficient opening and closing of the engine’s valves, which in turn affects the intake and exhaust processes. The screw allows for precise adjustments to be made to the rocker arm, ensuring that the valves operate within the manufacturer’s specified tolerances. This adjustment capability is crucial for the engine’s performance, as it helps in optimizing the valve timing and lift, which are critical for the engine’s overall efficiency and power output 2.

Key Features

The Rocker Lever Adjusting Screw is characterized by its durable construction and precision engineering. It is typically made from high-quality materials that offer resistance to wear and corrosion, ensuring longevity and reliability in demanding engine environments. The screw’s design incorporates features that allow for fine adjustments, which is essential for maintaining the precise valve clearances required for optimal engine performance. Additionally, the screw is engineered to be compatible with Cummins engines, ensuring seamless integration and operation within the valve train system 3.

Role in Truck Operation

In the context of truck operation, the Rocker Lever Adjusting Screw plays a role in ensuring the engine’s efficient performance. By maintaining proper valve clearance, the screw contributes to the engine’s fuel efficiency, power output, and overall reliability. This is particularly important in heavy-duty trucks, where engine performance directly impacts the vehicle’s operational capabilities and economic efficiency. The screw’s ability to facilitate precise adjustments ensures that the engine operates within its optimal parameters, enhancing the truck’s performance and longevity.

Benefits

The Rocker Lever Adjusting Screw offers several advantages that contribute to enhanced engine performance and reduced maintenance requirements. Its precise adjustment capability allows for fine-tuning of the valve train, which can lead to improved engine efficiency and power output. Additionally, the screw’s durable construction and compatibility with Cummins engines contribute to prolonged component lifespan, reducing the need for frequent replacements. This not only enhances the engine’s reliability but also contributes to lower overall maintenance costs.

Troubleshooting and Maintenance

Identifying common issues related to the Rocker Lever Adjusting Screw involves monitoring the engine’s performance for signs of improper valve operation, such as decreased power output or increased fuel consumption. Diagnostic procedures may include checking the valve clearances and inspecting the screw for signs of wear or damage. Recommended maintenance practices include regular inspection and adjustment of the screw to ensure it remains within the manufacturer’s specified tolerances. Additionally, ensuring the screw is clean and free from debris can help maintain its functionality and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product portfolio includes a wide range of engines and power solutions designed to meet the diverse needs of its customers, from light-duty to heavy-duty applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a leader in the engine manufacturing industry.

Cummins Rocker Lever Adjusting Screw 4006269 in Engine Applications

The Cummins Rocker Lever Adjusting Screw, part number 4006269, is a critical component in several engine models. This part is integral to the operation of the engine’s valve train, ensuring that the rocker levers maintain the correct clearance from the camshaft.

QSK78 Engine Series

In the QSK78 engine series, the Rocker Lever Adjusting Screw 4006269 is used to fine-tune the valve clearances. This engine series is known for its robust design and is commonly used in heavy-duty applications, such as marine and industrial settings. The precision of this screw ensures that the rocker arms operate smoothly, reducing wear and tear on the engine components.

CM500 Engine Series

Similarly, in the CM500 engine series, the Rocker Lever Adjusting Screw 4006269 plays a vital role. The CM500 engines are designed for on-highway applications, providing reliable power for various commercial vehicles. The screw’s role in maintaining proper valve clearance is crucial for the engine’s longevity and performance.

Application Across Cummins Engines

The Rocker Lever Adjusting Screw 4006269 is designed to be compatible with multiple Cummins engine models. Its application across different engine series highlights its versatility and importance in ensuring the smooth operation of the valve train. This part is engineered to withstand the rigors of heavy-duty use, providing durability and reliability in demanding environments.

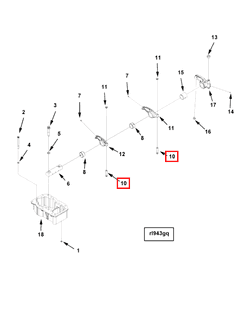

Role of Part 4006269 Rocker Lever Adjusting Screw in Engine Systems

The 4006269 Rocker Lever Adjusting Screw is an integral component in the precise operation of engine systems, particularly in the context of the rocker lever and rocker top level assembly lever mechanisms. This adjusting screw is designed to fine-tune the clearance between the camshaft and the rocker arm, ensuring optimal performance and longevity of the engine.

In the rocker lever system, the adjusting screw allows for the minute adjustments necessary to maintain the proper gap. This gap is essential for the efficient transfer of motion from the camshaft to the valves. Without proper adjustment, the engine may experience issues such as valve train noise, decreased performance, or even valve damage.

The rocker top level assembly lever, which includes the rocker arm and associated components, relies on the 4006269 screw to keep the system within specified tolerances. The screw’s role is to compensate for wear and thermal expansion, both of which can affect the clearance over time. By making precise adjustments, the screw helps to ensure that the rocker arm maintains consistent contact with the camshaft and pushrod, leading to smooth and reliable valve operation.

Conclusion

In summary, the 4006269 Rocker Lever Adjusting Screw is a key element in the maintenance and performance of engine systems. Its ability to provide fine-tuned adjustments is essential for the proper function of the rocker lever and rocker top level assembly lever, contributing to the overall efficiency and reliability of the engine.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.