This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Rocker Lever 4003926 is a component designed to enhance the operation of commercial trucks. This part is integral to the engine’s valve train system, ensuring efficient and reliable performance. Understanding its purpose and significance can help in maintaining and optimizing the truck’s engine functionality.

Basic Concepts of Rocker Levers

A rocker lever, also known as a rocker arm, is a pivotal component in an engine’s valve train. It operates on the principle of leverage, amplifying the motion from the camshaft to open and close the engine’s valves. This mechanism allows for precise control over the valve timing and lift, which are essential for the engine’s combustion process. Within the engine system, the rocker lever interacts with the camshaft, pushrods (in pushrod engines), and valves to facilitate the intake and exhaust cycles 1.

Purpose of Rocker Lever 4003926

The Cummins Rocker Lever 4003926 is designed to transfer motion from the camshaft to the valves in a truck’s engine. It plays a role in the valve train system by ensuring that the valves open and close at the correct times and with the appropriate force. This part interacts with other engine components such as the camshaft, pushrods, and valve springs to maintain the engine’s operational efficiency. Proper function of the rocker lever is vital for achieving optimal engine performance and fuel efficiency 2.

Key Features

The Rocker Lever 4003926 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, typically including heat-treated alloy steel, which provides strength and resistance to wear. The design incorporates precise engineering specifications to ensure smooth operation and longevity. Additionally, the rocker lever features a polished surface to reduce friction and wear, and it is designed to withstand high temperatures and pressures within the engine environment 3.

Benefits

The Rocker Lever 4003926 offers several advantages that contribute to improved engine performance. Its robust material composition and precise engineering result in enhanced durability and reliability. The reduced friction from the polished surface leads to smoother operation, which can improve fuel efficiency and reduce wear on other engine components. Additionally, the design of the rocker lever ensures consistent valve operation, which is essential for maintaining engine performance over time.

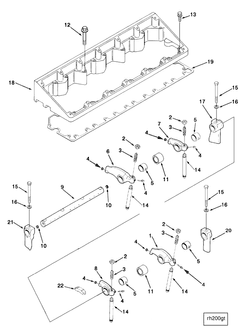

Installation Process

Installing the Rocker Lever 4003926 requires careful attention to detail to ensure proper function and longevity. The process involves several steps:

- Ensure the engine is cool and the valve cover is removed to access the valve train components.

- Use appropriate tools, such as a torque wrench, to remove the old rocker lever.

- Inspect the camshaft and valve surfaces for any damage or wear.

- Position the new Rocker Lever 4003926 onto the camshaft and align it with the pushrod and valve.

- Torque the rocker lever to the manufacturer’s specified settings to ensure proper tension and operation.

- Reinstall the valve cover and perform a thorough inspection to confirm that all components are securely in place.

Common Issues and Troubleshooting

Several issues can arise with the Rocker Lever 4003926, including noise, improper valve operation, and wear. Common problems and their solutions include:

- Noise: Excessive noise from the valve train may indicate improper installation or wear. Inspect the rocker lever and related components for proper alignment and condition.

- Improper Valve Operation: If the valves are not opening or closing correctly, check the rocker lever for proper seating and torque. Ensure there is no interference from other components.

- Wear: Visible wear on the rocker lever or related surfaces may require replacement of the affected parts. Regular inspection and maintenance can help identify and address wear before it leads to significant issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Rocker Lever 4003926, regular maintenance is recommended. This includes:

- Regular Inspections: Periodically check the rocker lever and related components for signs of wear or damage.

- Lubrication: Ensure that the valve train is properly lubricated to reduce friction and wear on the rocker lever.

- Torque Checks: Regularly verify that the rocker lever is torqued to the manufacturer’s specifications to maintain proper tension and operation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins is committed to innovation, quality, and customer satisfaction. The company’s extensive product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles and industrial equipment.

Cummins Rocker Lever 4003926 Compatibility

The Cummins Rocker Lever part number 4003926 is a critical component in the valve train system of certain engines. This part is designed to interface with the camshaft and the valve, ensuring smooth and reliable operation of the engine’s valves. Below is a detailed description of how this rocker lever fits with the specified engines.

L10 GAS and L10 MECHANICAL Engines

The Cummins Rocker Lever 4003926 is compatible with the L10 GAS and L10 MECHANICAL engines. These engines are known for their robust design and are often used in heavy-duty applications. The rocker lever’s role in these engines is to translate the rotational motion of the camshaft into the linear motion required to open and close the engine’s valves.

In the L10 GAS engine, the rocker lever works in conjunction with the fuel injection system to ensure precise valve timing and operation. This is crucial for maintaining the engine’s efficiency and performance, especially under varying load conditions.

Similarly, in the L10 MECHANICAL engine, the rocker lever is integral to the mechanical valve train system. It ensures that the valves open and close at the correct times, which is essential for the engine’s overall operation and longevity.

The compatibility of the Cummins Rocker Lever 4003926 with both the L10 GAS and L10 MECHANICAL engines underscores its versatility and importance in maintaining the functionality of these engines.

Part 4003926 Rocker Lever Component Usage

The part 4003926 Rocker Lever is an essential component in the operation of various engine systems. It is primarily responsible for transferring motion from the camshaft to the valves, ensuring precise timing and efficient engine performance.

Valve Train Mechanism

In the valve train mechanism, the Rocker Lever interacts directly with the camshaft and the valve. As the camshaft rotates, it pushes against the Rocker Lever, which then amplifies this motion to open the valve. This amplification is necessary because the camshaft’s motion is typically small, and the valve requires a larger movement to open and close effectively. The Rocker Lever ensures that the valve opens at the correct time and to the correct extent, which is vital for the engine’s combustion process 1.

Pushrod System

In engines that utilize a pushrod system, the Rocker Lever plays a significant role in transmitting motion from the camshaft, located in the engine block, to the valves situated in the cylinder head. The pushrod connects the camshaft to the Rocker Lever. As the camshaft lobe rises, it pushes the pushrod, which in turn pushes the Rocker Lever. The Rocker Lever then rocks on its pivot point and opens the valve. This system allows for a more compact engine design and is commonly found in overhead valve (OHV) engines 2.

Overhead Camshaft Engines

In overhead camshaft (OHC) engines, the Rocker Lever may still be present, though its role can vary depending on the engine’s design. In some OHC engines, the camshaft is positioned directly above the valves, and the Rocker Lever is used to provide additional mechanical advantage or to change the direction of the motion. This setup can help in reducing the forces acting on the camshaft and improving the overall efficiency of the valve operation 3.

Variable Valve Timing Systems

In engines equipped with variable valve timing (VVT) systems, the Rocker Lever can also play a role in adjusting the timing of the valve operation. VVT systems alter the timing of the valve opening and closing events to optimize engine performance across different operating conditions. The Rocker Lever, in conjunction with other components, helps to implement these timing changes by modifying the motion transmitted from the camshaft to the valve.

Performance and Efficiency

The precise function of the Rocker Lever in these systems directly impacts the engine’s performance and efficiency. By ensuring that the valves open and close at the optimal times and with the correct force, the Rocker Lever contributes to better fuel efficiency, increased power output, and reduced emissions. Additionally, the durability and design of the Rocker Lever are important for the longevity and reliability of the engine, as it must withstand the high stresses and temperatures within the engine compartment.

Conclusion

The Cummins Rocker Lever 4003926 is a critical component in the valve train system of commercial truck engines. Its role in transferring motion from the camshaft to the valves ensures precise timing and efficient engine performance. Understanding its features, benefits, and proper installation and maintenance procedures can help in optimizing the engine’s functionality and longevity.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.