This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

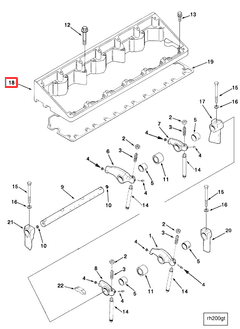

The Rocker Lever Housing, identified by part number 3062607, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This Cummins part plays a significant role in the engine system, ensuring the efficient operation of the valve train mechanism. Cummins is renowned for its high-quality engine components, and the Rocker Lever Housing is no exception, designed to meet the rigorous demands of heavy-duty applications 3.

Function and Operation

The Rocker Lever Housing operates within the engine by providing a secure mounting point for the rocker arms. These rocker arms are pivotal in transferring motion from the camshaft to the valves, thereby controlling the intake and exhaust processes. The housing interacts closely with the camshaft and valve train, ensuring precise and reliable valve operation. This interaction is crucial for maintaining the engine’s performance and efficiency 2.

Purpose of the Rocker Lever Housing

In the operation of a truck, the Rocker Lever Housing contributes to the engine’s efficiency and performance by ensuring that the valve train components function smoothly and accurately. It helps in maintaining the correct valve timing and lift, which are vital for optimal combustion and power output. The housing’s role in supporting the rocker arms directly influences the engine’s overall reliability and durability 1.

Key Features

The Rocker Lever Housing is characterized by its robust design and the use of high-quality materials, which enhance its durability and functionality. It is typically made from cast iron or a similar robust material to withstand the high stresses and temperatures within the engine compartment. The housing is designed to provide a precise fit for the rocker arms, ensuring minimal clearance and maximum efficiency. Additionally, it may feature integrated oil passages to facilitate lubrication, further enhancing its longevity and performance 3.

Benefits

The Rocker Lever Housing offers several advantages, including improved engine performance, enhanced durability, and increased reliability. By ensuring precise valve operation, it contributes to better fuel efficiency and reduced emissions. Its robust construction allows it to withstand the harsh conditions of heavy-duty applications, providing long-lasting service. Moreover, the housing’s design helps in reducing maintenance requirements, making it a cost-effective component for truck operators 2.

Installation Process

Proper installation of the Rocker Lever Housing is vital for ensuring its optimal performance and longevity. The process involves several steps:

- Preparation: Ensure the engine is clean and free from debris. Inspect the mating surfaces for any damage or irregularities.

- Alignment: Position the housing correctly over the mounting points on the engine block. Ensure it is aligned properly to avoid any binding or misalignment of the rocker arms.

- Securing: Use the appropriate fasteners to secure the housing in place. Tighten the bolts in a specified sequence to ensure even distribution of pressure and prevent warping.

- Lubrication: Apply a suitable lubricant to the rocker arm contact points to reduce friction and wear.

- Final Checks: Verify that the housing is securely mounted and that the rocker arms operate smoothly without any interference.

Common Issues and Troubleshooting

Typical problems associated with the Rocker Lever Housing include wear and tear, misalignment, and lubrication issues. Symptoms may include noisy valve operation, reduced engine performance, or increased oil consumption. Troubleshooting methods include:

- Inspection: Check for signs of wear or damage on the housing and rocker arms.

- Alignment: Ensure that the housing is correctly aligned and securely mounted.

- Lubrication: Verify that adequate lubrication is present and that oil passages are clear.

- Replacement: If significant wear or damage is detected, consider replacing the housing to restore optimal performance.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and optimal performance of the Rocker Lever Housing. These include:

- Periodic Inspection: Regularly check the housing for signs of wear, damage, or misalignment.

- Lubrication: Ensure that the rocker arms and contact points are properly lubricated.

- Cleanliness: Keep the engine compartment clean to prevent debris from interfering with the housing’s operation.

- Tightening: Periodically check and tighten the fasteners securing the housing to prevent loosening over time.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies and services. Cummins is committed to sustainability and efficiency, providing solutions that meet the evolving needs of its customers 3.

Conclusion

The Rocker Lever Housing, part number 3062607, is a critical component in the engine assembly of various models. Its role in supporting the rocker lever is essential for the smooth and efficient operation of the engine, influencing both power output and fuel efficiency. Proper installation, regular maintenance, and timely troubleshooting are key to ensuring the longevity and optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.