This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5320969 Wiring Harness Assembly is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This assembly ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harness Assembly

A wiring harness assembly is a collection of wires, connectors, and components that are bundled together to transmit electrical power and signals within a vehicle. It typically includes wires of various gauges, connectors, terminals, and sometimes fuses or relays. The primary function of a wiring harness is to organize and protect the electrical connections, reducing the risk of short circuits and ensuring reliable performance of the vehicle’s electrical systems 1.

Role of the 5320969 Wiring Harness Assembly in Truck Operation

The 5320969 Wiring Harness Assembly plays a specific role in the electrical system of a truck by providing a structured pathway for electrical current to flow between the battery, engine control module (ECM), sensors, and other electrical components. It ensures that all electrical systems receive the necessary power and signals to operate correctly. This assembly interacts with other components such as the ECM, sensors, and actuators, enabling the truck to perform various functions, including engine management, transmission control, and diagnostic monitoring 2.

Key Features

The 5320969 Wiring Harness Assembly is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to corrosion, abrasion, and extreme temperatures. The assembly is designed to withstand the harsh conditions typically encountered in commercial truck operations. Additionally, it features precise engineering to ensure a perfect fit and reliable connections, enhancing the overall performance and longevity of the truck’s electrical system 3.

Benefits of Using the 5320969 Wiring Harness Assembly

Utilizing the 5320969 Wiring Harness Assembly offers several advantages. It provides improved reliability by ensuring secure and consistent electrical connections. The assembly enhances efficiency by reducing the risk of electrical faults and minimizing power loss. Furthermore, it contributes to safety by maintaining the integrity of the electrical system, which is crucial for the proper functioning of safety-critical components such as brakes and lights 4.

Installation Process

Installing the 5320969 Wiring Harness Assembly requires careful attention to detail. The process involves disconnecting the battery to prevent electrical shocks, routing the harness through the designated pathways in the truck, and connecting it to the appropriate terminals and components. It is important to follow the manufacturer’s instructions and use the correct tools to ensure a secure and proper installation. Additionally, verifying all connections and performing a system check post-installation is recommended to confirm that the harness is functioning correctly.

Maintenance and Troubleshooting

Maintaining the 5320969 Wiring Harness Assembly involves regular inspections for signs of wear, corrosion, or damage. Common issues may include frayed wires, loose connections, or faulty connectors. Troubleshooting techniques include visual inspections, using a multimeter to test for continuity, and consulting the vehicle’s diagnostic system for error codes. Preventive maintenance measures such as keeping the harness clean and dry, and protecting it from physical damage, can help extend its lifespan and ensure reliable performance.

Compatibility and Applications

The 5320969 Wiring Harness Assembly is designed to be compatible with specific models of commercial trucks. Its applications span various commercial truck settings, including long-haul transportation, construction, and logistics. The assembly is engineered to meet the demanding requirements of these environments, ensuring reliable electrical performance under a wide range of operating conditions.

Safety Considerations

When working with the 5320969 Wiring Harness Assembly, it is important to observe safety protocols to protect both personnel and equipment. This includes disconnecting the battery before beginning any work, using insulated tools to prevent electrical shocks, and wearing appropriate personal protective equipment (PPE). Additionally, ensuring that the work area is well-ventilated and free from flammable materials is crucial to maintaining a safe working environment.

Environmental Impact

The production, use, and disposal of the 5320969 Wiring Harness Assembly have environmental considerations. Cummins Inc. is committed to minimizing the environmental footprint of its products through sustainable manufacturing practices, the use of recyclable materials, and responsible disposal methods. Efforts are made to reduce waste, conserve energy, and lower emissions throughout the product lifecycle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success. The company offers a wide range of products and services for various industries, including automotive, construction, and power generation, consistently delivering reliable and high-performance solutions.

Integration with Cummins Engines

ISL G CM2180

The Wiring Harness Assembly part 5320969 is specifically tailored to fit the ISL G CM2180 engine. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The wiring harness ensures that all electrical components are properly connected, enhancing the engine’s operational efficiency and longevity.

Other Cummins Engines

While the primary focus is on the ISL G CM2180, the part 5320969 is also compatible with other Cummins engines within the same series. This compatibility ensures that the wiring harness can be used across multiple engine models, providing a standardized solution for electrical connectivity. The design of the harness is such that it can be easily integrated into the engine’s architecture, ensuring a secure and efficient fit.

Compatibility and Installation

The installation of the Wiring Harness Assembly part 5320969 is straightforward, thanks to its precise engineering. Technicians can expect a seamless integration process, minimizing downtime and ensuring that the engine can return to operation quickly. The harness is designed to withstand the rigors of heavy-duty use, providing a durable and reliable solution for electrical connectivity.

Importance of the Wiring Harness

The Wiring Harness Assembly part 5320969 plays a role in the overall functionality of the engine. By ensuring that all electrical components are properly connected, it helps to maintain the engine’s performance and reliability. This part is essential for the efficient operation of the engine, making it a vital component for any Cummins engine user.

Role of Part 5320969 Wiring Harness Assembly in Engine Systems

The Part 5320969 Wiring Harness Assembly is an integral component in the electrical system of an engine, facilitating the connection between various electrical components and the power source. Its primary function is to transmit electrical power and signals efficiently and reliably throughout the engine system.

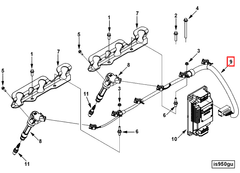

Integration with the Ignition System

In the ignition system, the Wiring Harness Assembly serves as the backbone for electrical distribution. It connects the ignition coil to the spark plugs, ensuring that the high voltage required for spark generation is delivered accurately. This assembly also interfaces with the ignition control module, allowing for precise timing of the spark in relation to the engine’s operation. Additionally, it links the ignition switch to the system, enabling the driver to start and stop the engine with ease.

Role in the Engine System

Beyond the ignition system, the Wiring Harness Assembly plays a significant role in the broader engine system. It provides power to essential components such as the fuel injectors, ensuring that fuel is delivered at the correct moments in the combustion cycle. The assembly also connects sensors throughout the engine, such as the oxygen sensor and the crankshaft position sensor, to the engine control unit (ECU). This allows the ECU to monitor engine performance in real-time and make necessary adjustments for optimal operation.

Furthermore, the Wiring Harness Assembly is responsible for powering ancillary components like the alternator, which charges the battery while the engine is running, and the starter motor, which cranks the engine during startup. It also facilitates communication between the ECU and other control modules within the vehicle, ensuring a cohesive and efficient operation of all engine-related systems.

Conclusion

In summary, the Part 5320969 Wiring Harness Assembly is a vital component that ensures the seamless operation of the engine’s electrical systems, contributing to the overall performance and reliability of the engine.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.