This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5292281 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a critical part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power from the battery to various electrical components, such as lights, sensors, and control units, ensuring they operate correctly 1.

Purpose of the Cummins 5292281 Wiring Harness

The Cummins 5292281 Wiring Harness is designed to facilitate the electrical connections required for the operation of a truck’s engine and related systems. It integrates with the engine control module (ECM), sensors, and other electrical components, allowing for the efficient transmission of power and signals. This harness plays a role in ensuring that all electrical components receive the necessary power and signals to function correctly, contributing to the overall performance and reliability of the truck 2.

Key Features

The Cummins 5292281 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features insulated wires to prevent short circuits, durable connectors for secure connections, and protective housing to shield the wires from damage. Unique attributes of this wiring harness include its compatibility with specific Cummins engine models and its design to withstand the harsh conditions often encountered in commercial truck operations 3.

Benefits of Using the Cummins 5292281 Wiring Harness

Utilizing the Cummins 5292281 Wiring Harness offers several advantages. Its design contributes to the reliability of the truck’s electrical system by ensuring secure and durable connections. The efficiency of the harness in transmitting power and signals helps maintain the optimal performance of electrical components. Additionally, its design facilitates ease of installation, reducing the time and effort required for setup 4.

Installation Process

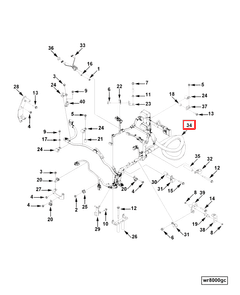

Installing the Cummins 5292281 Wiring Harness involves several steps to ensure proper integration with the truck’s electrical system. Begin by identifying the correct location for the harness within the truck’s engine compartment. Use the provided connectors to link the harness with the engine control module, sensors, and other components. Secure the harness in place using the supplied mounting brackets and fasteners. Finally, test the electrical connections to confirm they are secure and functioning correctly.

Maintenance and Troubleshooting

Maintaining the Cummins 5292281 Wiring Harness involves regular inspections for signs of wear, damage, or corrosion. Common issues may include loose connections, damaged wires, or faulty connectors. Troubleshooting methods include checking for continuity in the wires, ensuring connectors are securely attached, and replacing any damaged components as necessary. Regular maintenance helps ensure the longevity and reliability of the wiring harness.

Safety Considerations

When working with the Cummins 5292281 Wiring Harness, it is important to follow electrical safety practices. This includes ensuring the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Use appropriate tools and equipment for installation and maintenance tasks. Handle the wiring harness with care to avoid damaging the wires or connectors. Adhering to these safety practices helps protect both the individual and the vehicle’s electrical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is known for its high-quality engines and components, which are designed to meet the demanding requirements of commercial truck operations. Cummins plays a significant role in the industry by providing reliable and efficient power solutions for a wide range of applications.

Conclusion

The Cummins 5292281 Wiring Harness is a critical component in the electrical system of commercial trucks, ensuring reliable operation and safety. Its robust design, compatibility with specific Cummins engine models, and ease of installation make it a valuable part for maintaining the performance and reliability of commercial vehicles. Regular maintenance and adherence to safety practices are essential for the longevity and effectiveness of this part.

-

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.