This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Wiring harnesses are integral components in vehicles, designed to organize and route electrical cables and wires efficiently. Their primary purpose is to ensure reliable electrical connections throughout the vehicle, contributing significantly to the functionality of the electrical system. By consolidating wires into a single unit, wiring harnesses reduce the complexity of the electrical system, minimize the risk of short circuits, and enhance the overall reliability of electrical connections 1.

Purpose of the Cummins 4968708 Wiring Harness

The Cummins 4968708 Wiring Harness is specifically engineered for commercial trucks, playing a vital role in their operation. It facilitates the connection between various electrical components and systems within the truck, ensuring seamless communication and operation. This wiring harness is designed to support the truck’s electrical needs, from powering essential systems to enabling advanced features, thereby contributing to the truck’s overall performance and efficiency 2.

Key Features of the Cummins 4968708 Wiring Harness

The Cummins 4968708 Wiring Harness is characterized by several notable features and design elements that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the demanding conditions of commercial truck environments. Its design includes robust connectors and terminals that ensure secure and reliable connections. Additionally, the harness is engineered with flexibility and durability in mind, allowing it to adapt to the dynamic movements and vibrations inherent in truck operations 3.

Benefits of Using the Cummins 4968708 Wiring Harness

Utilizing the Cummins 4968708 Wiring Harness in commercial trucks offers several advantages. It contributes to improved electrical efficiency by ensuring that power is distributed effectively throughout the truck’s systems. The design of the harness reduces the risk of short circuits, enhancing the safety and reliability of the electrical system. Furthermore, its robust construction and high-quality materials ensure longevity, providing commercial truck operators with a dependable solution for their electrical needs.

Installation and Compatibility

Proper installation of the Cummins 4968708 Wiring Harness is crucial for ensuring optimal performance and integration within the vehicle’s electrical system. Guidelines for installation should be followed carefully to avoid common pitfalls and ensure compatibility with the truck’s existing systems. While specific compatibility details are provided separately, it is important to consider the harness’s design and construction when integrating it into different truck models and engine types.

Troubleshooting and Maintenance

Regular maintenance and proper troubleshooting techniques are key to ensuring the longevity and effectiveness of the Cummins 4968708 Wiring Harness. Common issues may include loose connections, damaged wires, or faulty components. Inspection procedures should be conducted at recommended intervals to identify and address potential problems early. Maintenance practices, such as cleaning connectors and checking for wear and tear, can help prevent issues and ensure the harness continues to operate efficiently.

Safety Considerations

When working with the Cummins 4968708 Wiring Harness, observing safety protocols and precautions is paramount. Proper handling, installation, and maintenance practices are necessary to prevent electrical hazards and ensure the safety of both the vehicle and its occupants. This includes adhering to manufacturer guidelines, using appropriate tools and equipment, and ensuring that all connections are secure and correctly installed.

Cummins: A Brief Overview

Cummins Inc. is a renowned leader in the automotive and commercial vehicle industries, with a rich history of innovation, quality, and customer satisfaction. The company is committed to designing and manufacturing high-quality automotive components, including wiring harnesses, that meet the demanding needs of commercial vehicles. Cummins’ dedication to excellence is evident in the performance, reliability, and durability of its products, making it a trusted name in the industry.

Cummins Engine Wiring Harness 4968708 Compatibility

The Cummins Wiring Harness part number 4968708 is designed to integrate seamlessly with specific Cummins engine models. This wiring harness is a critical component that ensures the electrical systems of the engines function correctly, facilitating communication between various engine control units and auxiliary systems.

QSK50 Engines

The QSK50 engine series, including the QSK50 CM2150 K107 and QSK50 CM2150 MCRS models, are high-performance engines widely used in various industrial applications. The wiring harness 4968708 is engineered to fit these engines by providing a robust and reliable electrical connection. This ensures that the engine’s control systems, sensors, and other electrical components operate efficiently and without interruption.

-

QSK50 CM2150 K107: This model is known for its durability and efficiency in demanding environments. The wiring harness 4968708 is specifically tailored to meet the electrical requirements of this engine, ensuring optimal performance and longevity.

-

QSK50 CM2150 MCRS: This variant is designed for applications requiring high reliability and performance. The wiring harness 4968708 is compatible with this engine, providing a seamless integration that supports the engine’s advanced control systems and diagnostic capabilities.

Integration and Installation

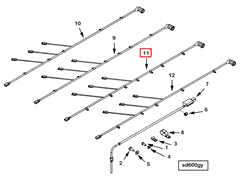

The installation of the wiring harness 4968708 in the QSK50 engines involves connecting it to various electrical components, including the engine control unit (ECU), sensors, and other auxiliary systems. Proper installation is crucial to ensure that the engine operates smoothly and that all electrical systems function as intended. Technicians should follow the manufacturer’s guidelines and use the appropriate tools to ensure a secure and reliable connection.

Compatibility and Performance

The compatibility of the wiring harness 4968708 with the QSK50 engines is a result of rigorous testing and design. This ensures that the harness can handle the electrical demands of the engine and provide a stable connection even under harsh operating conditions. The use of high-quality materials and precise engineering guarantees that the wiring harness will perform reliably over the engine’s operational life.

Role of Part 4968708 Wiring Harness in Engine Systems

The 4968708 Wiring Harness is an integral component in the electrical system of various engine setups. It serves as the vital link between the sensor and the engine’s control unit, facilitating the transmission of data and power.

In the context of the Exhaust Gas Temperature (EGT) sensor, the wiring harness is responsible for connecting the sensor to the engine control module (ECM). This connection allows the EGT sensor to monitor the temperature of the exhaust gases. The data collected is then sent to the ECM, which uses this information to adjust the fuel injection timing and air-fuel ratio for optimal engine performance and efficiency.

Additionally, the wiring harness ensures that the sensor receives the necessary power supply to function correctly. It also protects the electrical connections from environmental factors such as moisture, vibration, and physical damage, which could otherwise lead to sensor malfunction or failure.

Conclusion

In summary, the Cummins 4968708 Wiring Harness plays a significant role in maintaining the integrity and reliability of the engine’s electrical system, particularly in relation to the EGT sensor. Its proper installation and maintenance are essential for the accurate monitoring and control of engine operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.