This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4924942 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to operate correctly 1.

Purpose of the 4924942 Wiring Harness

The Cummins 4924942 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This harness plays a role in the efficient distribution of electrical power and signals, ensuring that all connected components function as intended. Its design allows for seamless integration with other systems and components within the truck, enhancing overall vehicle performance.

Key Features

The Cummins 4924942 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, insulated wires that resist wear and environmental damage. The harness features precise connectors that ensure secure and reliable connections between components. Additionally, its design includes protective housing to shield the wires from physical damage, moisture, and other potential hazards, contributing to its longevity and performance.

Benefits of Using the 4924942 Wiring Harness

Utilizing the Cummins 4924942 Wiring Harness in commercial trucks offers several advantages. It enhances the reliability of the truck’s electrical system by ensuring consistent and efficient power distribution. The harness contributes to improved efficiency by minimizing electrical losses and ensuring that components receive the correct voltage and signals. Furthermore, it plays a role in enhancing safety by maintaining the integrity of the electrical connections, reducing the risk of electrical faults or failures 2.

Installation Considerations

When installing the Cummins 4924942 Wiring Harness, it is important to follow guidelines and best practices to ensure proper integration with the truck’s electrical system. This includes verifying that all prerequisites are met, such as having the correct tools and ensuring the truck’s electrical system is prepared for the installation. Careful attention to the installation steps helps ensure that the harness is correctly connected and functions as intended within the vehicle’s electrical network.

Troubleshooting Common Issues

Common problems associated with wiring harnesses can include loose connections, damaged wires, or faulty connectors. Diagnosing these issues involves inspecting the harness for visible signs of damage, testing electrical connections for continuity, and using diagnostic tools to identify any irregularities in the electrical system. Resolving these issues may require repairing or replacing damaged sections of the harness, ensuring all connections are secure, and verifying that the electrical system operates correctly.

Maintenance Tips

To prolong the lifespan and performance of the Cummins 4924942 Wiring Harness, routine maintenance practices are recommended. This includes regular inspection of the harness for signs of wear or damage, cleaning connectors to ensure good electrical contact, and protecting the harness from physical damage and environmental factors. Preventive measures, such as using cable ties to secure the harness and applying protective coatings, can also contribute to its durability and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the diverse needs of its customers, contributing to the efficiency, performance, and sustainability of commercial transportation.

Compatibility with Engine Models

The Cummins Wiring Harness part number 4924942 is designed to fit seamlessly with specific engine models, ensuring reliable power distribution and communication between various engine components.

QSK60 Engine

The QSK60 engine, known for its robust performance and efficiency, is compatible with the 4924942 wiring harness. This harness is engineered to integrate with the QSK60’s electrical architecture, providing essential connections for sensors, actuators, and control modules. Its design ensures that the engine’s complex systems operate smoothly, enhancing overall performance and reliability.

CM850 and MCRS Engines

The CM850 and MCRS engines, both part of Cummins’ lineup of medium-duty engines, also utilize the 4924942 wiring harness. This harness is tailored to fit these engines’ specific electrical requirements, ensuring that all critical systems are properly connected and powered. The compatibility of this wiring harness with these engines is crucial for maintaining optimal engine performance and ensuring that all electronic components function as intended.

Role of the 4924942 Wiring Harness in Engine Systems

The 4924942 Wiring Harness is an integral component that facilitates the electrical connections within various engine systems. Its primary function is to ensure reliable and efficient transmission of electrical signals and power between different engine components.

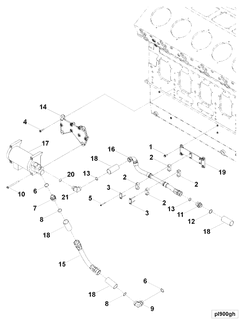

Integration with Engine Components

-

Arrangement: The wiring harness is meticulously arranged to interface with multiple engine components. This arrangement ensures that all electrical connections are secure and properly insulated, minimizing the risk of short circuits and ensuring optimal performance.

-

Engine Lubrication Primer: The wiring harness plays a significant role in the operation of the engine lubrication primer. It provides the necessary electrical connections that allow the primer to function correctly, ensuring that the engine receives adequate lubrication before start-up. This is essential for reducing wear and tear on engine components.

-

Primer: In conjunction with the engine lubrication primer, the wiring harness ensures that the primer system receives the correct electrical signals to activate at the appropriate times. This timing is vital for the primer to effectively prepare the engine for operation, enhancing overall engine efficiency and reliability.

-

Engine Lubricating System: The wiring harness is also responsible for connecting various sensors and actuators within the engine lubricating system. These connections allow for real-time monitoring and control of the lubrication process, ensuring that the engine maintains optimal lubrication levels throughout its operation.

By seamlessly integrating with these components, the 4924942 Wiring Harness ensures that the engine systems operate harmoniously, contributing to the engine’s overall performance and longevity.

Conclusion

The Cummins 4924942 Wiring Harness is a critical component in the electrical systems of commercial trucks and specific Cummins engines. Its robust design, high-quality materials, and precise connectors ensure reliable and efficient power distribution, enhancing the overall performance and safety of the vehicle. Proper installation, maintenance, and troubleshooting practices are essential to maximize the benefits of this Cummins part, ensuring that it continues to function effectively within the vehicle’s electrical network.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.