This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

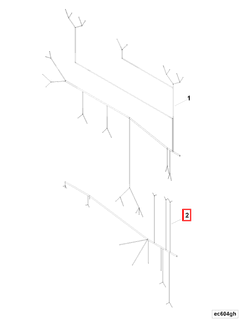

Wiring harnesses are essential components in the electrical systems of commercial trucks. They consist of a collection of wires, connectors, and terminals that facilitate the transmission of electrical signals and power throughout the vehicle. The primary function of a wiring harness is to organize and protect the electrical cables, ensuring efficient and reliable operation of the truck’s various electrical systems. This organization reduces the risk of short circuits, enhances safety, and simplifies the installation and maintenance processes 1.

Function and Role of the 4310101 Wiring Harness

The 4310101 Wiring Harness by Cummins is designed to play a specific role within the electrical system of a truck. It connects various electrical components, ensuring seamless communication and power distribution. This harness integrates with the truck’s engine control module (ECM), sensors, and other critical systems, allowing for precise control and monitoring of engine functions. By providing a structured pathway for electrical signals, the 4310101 Wiring Harness contributes to the overall efficiency and performance of the truck’s electrical system 2.

Key Features of the 4310101 Wiring Harness

The 4310101 Wiring Harness is constructed with high-quality materials to ensure durability and reliability. It features robust connectors and terminals that are designed to withstand the harsh conditions often encountered in commercial trucking environments. The harness is built with precision, ensuring a snug fit and secure connections. Additionally, it includes protective coatings and shielding to guard against environmental factors such as moisture, dust, and vibrations. These features contribute to the longevity and consistent performance of the wiring harness 3.

Benefits of Using the 4310101 Wiring Harness

Utilizing the 4310101 Wiring Harness offers several advantages. Its design enhances the reliability of the truck’s electrical system by providing a well-organized and protected pathway for electrical signals. The harness simplifies the installation process, reducing the time and effort required for setup. Furthermore, its high build quality ensures consistent performance, minimizing the likelihood of electrical issues. These benefits contribute to improved overall vehicle operation and maintenance efficiency.

Installation and Compatibility

Proper installation of the 4310101 Wiring Harness is crucial for optimal performance. It is important to follow the manufacturer’s guidelines to ensure correct integration with the truck’s electrical system. The harness is designed to be compatible with a range of truck models and engine types, though specific compatibility details should be verified to ensure a proper fit. Careful attention to installation procedures will help maintain the integrity of the electrical system and ensure the harness functions as intended.

Maintenance and Troubleshooting

Regular maintenance of the 4310101 Wiring Harness is important to ensure continued reliable operation. This includes periodic inspections for signs of wear, corrosion, or damage. Any issues identified should be addressed promptly to prevent further complications. Common troubleshooting steps involve checking connections, ensuring terminals are secure, and verifying that protective coatings remain intact. Proactive maintenance practices help extend the lifespan of the wiring harness and maintain the efficiency of the truck’s electrical system.

Safety and Regulatory Compliance

The 4310101 Wiring Harness meets safety standards and regulatory requirements for commercial vehicle electrical systems. It is designed to comply with industry regulations, ensuring that it operates safely within the specified parameters. This compliance not only enhances the safety of the vehicle but also ensures that the truck meets legal requirements for operation on public roads. Users can have confidence in the harness’s ability to perform reliably while adhering to necessary safety standards.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a strong reputation in the industry for producing high-quality automotive and heavy-duty truck parts. With a history of innovation and commitment to excellence, Cummins has established itself as a leader in the field. Their products are known for their durability, performance, and reliability, making them a preferred choice for commercial vehicle applications. Cummins’ dedication to quality and continuous improvement ensures that their wiring harnesses, including the 4310101, meet the demanding requirements of modern trucking operations.

Cummins Wiring Harness 4310101 Compatibility with Engine Models

The Cummins Wiring Harness 4310101 is designed to integrate seamlessly with various engine models, ensuring reliable electrical connectivity and performance. This wiring harness is engineered to meet the specific electrical needs of the engines it supports, providing a robust and efficient solution for power distribution and control.

K50 Engine Series

The K50 engine series, known for its durability and efficiency, is one of the key beneficiaries of the 4310101 wiring harness. This harness is meticulously crafted to fit the intricate electrical architecture of the K50 engines, ensuring that all components receive the necessary power and signals. The design of the harness allows for easy installation and maintenance, making it a preferred choice for both original equipment manufacturers (OEMs) and aftermarket users.

The compatibility of the 4310101 wiring harness with the K50 engines is achieved through precise engineering and adherence to stringent quality standards. Cummins ensures that the harness is compatible with the specific electrical requirements of the K50 series, which includes various configurations and power outputs. This compatibility extends to both standard and high-performance variants within the K50 series, providing a versatile solution for a wide range of applications.

In summary, the Cummins Wiring Harness 4310101 is a critical component for the K50 engine series, offering a reliable and efficient means of managing electrical connections. Its design and engineering make it an essential part of the engine’s overall performance and longevity.

Role of Part 4310101 Wiring Harness in Engine Systems

The Part 4310101 Wiring Harness is an integral component in the electrical system of engine assemblies, facilitating the seamless transmission of electrical power and signals between various engine components. This wiring harness is meticulously designed to interface with a multitude of engine subsystems, ensuring efficient and reliable operation.

Integration with Engine Components

-

Sensors and Actuators: The wiring harness serves as the conduit for electrical signals between the engine control unit (ECU) and an array of sensors and actuators. It ensures that data from oxygen sensors, throttle position sensors, and manifold absolute pressure sensors is accurately transmitted to the ECU. Conversely, it relays commands from the ECU to actuators such as fuel injectors, ignition coils, and variable valve timing solenoids, enabling precise control over engine performance.

-

Power Distribution: A key function of the wiring harness is the distribution of electrical power from the battery to essential engine components. This includes supplying power to the starter motor, alternator, and various auxiliary systems such as the fuel pump and cooling fan. The harness is engineered to handle the electrical load efficiently, minimizing voltage drop and ensuring consistent performance across all connected components.

-

Grounding: Effective grounding is vital for the proper functioning of the engine’s electrical system. The wiring harness incorporates dedicated ground wires that connect critical components to the engine block or chassis, providing a low-resistance path for electrical current. This not only enhances the reliability of electrical signals but also helps in dissipating electromagnetic interference, contributing to the overall stability of the engine’s electrical system.

-

Communication Networks: In modern engine systems, the wiring harness plays a pivotal role in facilitating communication between different control modules. It supports data exchange via protocols such as Controller Area Network (CAN) bus, allowing for coordinated operation of the engine, transmission, and other vehicle systems. This integration enhances diagnostic capabilities, enabling more efficient troubleshooting and maintenance.

-

Safety and Redundancy: The design of the wiring harness often includes redundancy features to enhance safety and reliability. For instance, critical circuits may have backup pathways to ensure continued operation in the event of a primary circuit failure. Additionally, the harness is protected against environmental factors such as moisture, heat, and mechanical stress, further safeguarding the integrity of the engine’s electrical system.

In summary, the Part 4310101 Wiring Harness is a foundational element in the electrical architecture of engine systems, supporting a wide range of functions from power distribution to signal transmission and system integration. Its robust design and precise engineering are essential for the reliable and efficient operation of modern engines.

Conclusion

The 4310101 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks and engines. Its role in organizing and protecting electrical cables, ensuring efficient power distribution, and facilitating communication between various engine components is indispensable. The harness’s high-quality construction, compatibility with a range of engine models, and adherence to safety standards make it a reliable choice for both OEMs and aftermarket users. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part, ensuring the overall efficiency and safety of the vehicle’s electrical system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.