This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4017382 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This part is significant due to its role in ensuring the reliable and efficient operation of the truck’s electrical systems.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle 1. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce electrical interference. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for electrical distribution, ensuring that power and signals reach their intended destinations efficiently and safely.

Purpose of the 4017382 Wiring Harness

The Cummins 4017382 Wiring Harness is designed to serve specific functions within the electrical system of a truck. It connects various electrical components, such as sensors, lights, and control modules, to the truck’s power source. This harness plays a role in facilitating communication between different parts of the truck’s electrical system, ensuring that all components operate in unison. Its applications include supporting the truck’s engine management system, lighting, and other critical electrical functions.

Key Features

The Cummins 4017382 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The harness is engineered to withstand the vibrations and harsh conditions typical of truck environments. Additionally, it features precise wiring and connector placements to ensure optimal functionality and ease of installation.

Benefits of Using the 4017382 Wiring Harness

Utilizing the Cummins 4017382 Wiring Harness offers several advantages. It contributes to improved efficiency within the truck’s electrical system by providing a reliable and organized method for power distribution. The harness enhances the reliability of electrical connections, reducing the likelihood of failures and malfunctions. Furthermore, it plays a role in promoting safety by ensuring that electrical components operate correctly, minimizing the risk of electrical fires or other hazards.

Installation Process

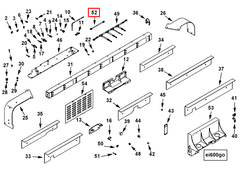

Installing the Cummins 4017382 Wiring Harness requires careful attention to detail to ensure proper functionality. The process involves identifying the correct location for the harness within the truck’s electrical system, routing the wires according to the manufacturer’s specifications, and securing the harness in place. Tools such as wire strippers, crimping tools, and electrical tape may be required. It is important to follow the installation instructions provided by Cummins to ensure a successful and safe installation.

Common Issues and Troubleshooting

Wiring harnesses, including the Cummins 4017382, may encounter issues such as loose connections, damaged wires, or corrosion. Common problems can lead to electrical malfunctions or failures. Troubleshooting these issues involves inspecting the harness for visible damage, checking connections for tightness, and testing electrical continuity. Addressing problems promptly can prevent more significant issues and ensure the continued reliable operation of the truck’s electrical system.

Maintenance Tips

Regular maintenance of the Cummins 4017382 Wiring Harness is vital for ensuring its longevity and optimal performance. Maintenance practices include inspecting the harness for signs of wear or damage, cleaning connections to prevent corrosion, and ensuring that all components are securely connected. Periodically reviewing the harness’s condition and addressing any issues can help maintain the efficiency and reliability of the truck’s electrical system.

Safety Considerations

When working with the Cummins 4017382 Wiring Harness, it is important to follow safety guidelines to prevent accidents and ensure safe operation. This includes disconnecting the truck’s battery before beginning any work on the electrical system, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. Adhering to these safety practices can help protect both the technician and the vehicle from potential hazards.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations.

Cummins Engine Wiring Harness 4017382

The Cummins Wiring Harness part number 4017382 is a critical component designed to integrate seamlessly with the Cummins QSK45 CM500 and QSK60 CM500 engines. This wiring harness is engineered to ensure reliable electrical connections and efficient power distribution across the engine’s various systems.

For the QSK45 CM500 engine, the wiring harness is meticulously crafted to interface with the engine’s control systems, sensors, and actuators. It ensures that all electrical signals are transmitted accurately and without interference, which is crucial for maintaining optimal engine performance and reliability.

Similarly, for the QSK60 CM500 engine, the wiring harness is designed to handle the increased electrical demands and complexity of this larger engine. It provides a robust and secure connection for the engine’s extensive network of sensors, control units, and other electrical components. This ensures that the engine operates smoothly and efficiently, even under heavy load conditions.

Both engines benefit from the precision engineering of the wiring harness, which is built to withstand the harsh operational environments typical of industrial and marine applications. The harness is designed to be durable, with high-quality materials that resist wear and corrosion, ensuring a long service life and minimal maintenance requirements.

In summary, the Cummins Wiring Harness part number 4017382 is an essential component for both the QSK45 CM500 and QSK60 CM500 engines, providing a reliable and efficient means of managing the electrical systems of these powerful engines.

Role of Part 4017382 Wiring Harness in Engine Systems

The 4017382 Wiring Harness is a component that facilitates the electrical connectivity within various engine systems. It ensures seamless communication and power distribution among different parts, enhancing the overall functionality and reliability of the engine.

Integration with Accessories

The Wiring Harness plays a role in connecting various accessories to the engine system. These accessories may include fuel pumps, ignition systems, and emission control devices. By providing a structured pathway for electrical signals and power, the harness ensures that these accessories operate efficiently and in sync with the engine’s performance.

Electrical System Coordination

In the electrical system, the 4017382 Wiring Harness acts as the backbone, linking sensors, actuators, and control modules. It allows for the precise transmission of data and power, enabling real-time monitoring and adjustments. This coordination is vital for maintaining optimal engine performance and ensuring that all electrical components function harmoniously.

Mounting and Structural Support

Beyond its electrical functions, the Wiring Harness also offers structural support. It is often mounted in a way that protects the wires from physical damage and environmental factors. This mounting ensures that the electrical connections remain intact under various operating conditions, contributing to the durability and longevity of the engine system.

Engine Monitor Connectivity

The Wiring Harness is integral to the engine monitor system, providing the necessary connections for data acquisition and feedback. It links the engine monitor to various sensors distributed throughout the engine, allowing for comprehensive monitoring of parameters such as temperature, pressure, and fuel efficiency. This connectivity enables engineers and mechanics to diagnose issues promptly and make informed adjustments to enhance engine performance.

Conclusion

The Cummins 4017382 Wiring Harness is a vital component in the electrical systems of commercial trucks, particularly for the Cummins QSK45 CM500 and QSK60 CM500 engines. Its design ensures reliable electrical connections, efficient power distribution, and seamless integration with various engine accessories and systems. Regular maintenance and adherence to safety guidelines are essential for maximizing the performance and longevity of this part.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.